Agricultural vibratory screening device for coarse grain

A vibratory screening and coarse grain technology, which is applied in the fields of screening, transportation and packaging, conveyor objects, etc., can solve the problems of heavy labor and achieve the effect of convenient collection and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

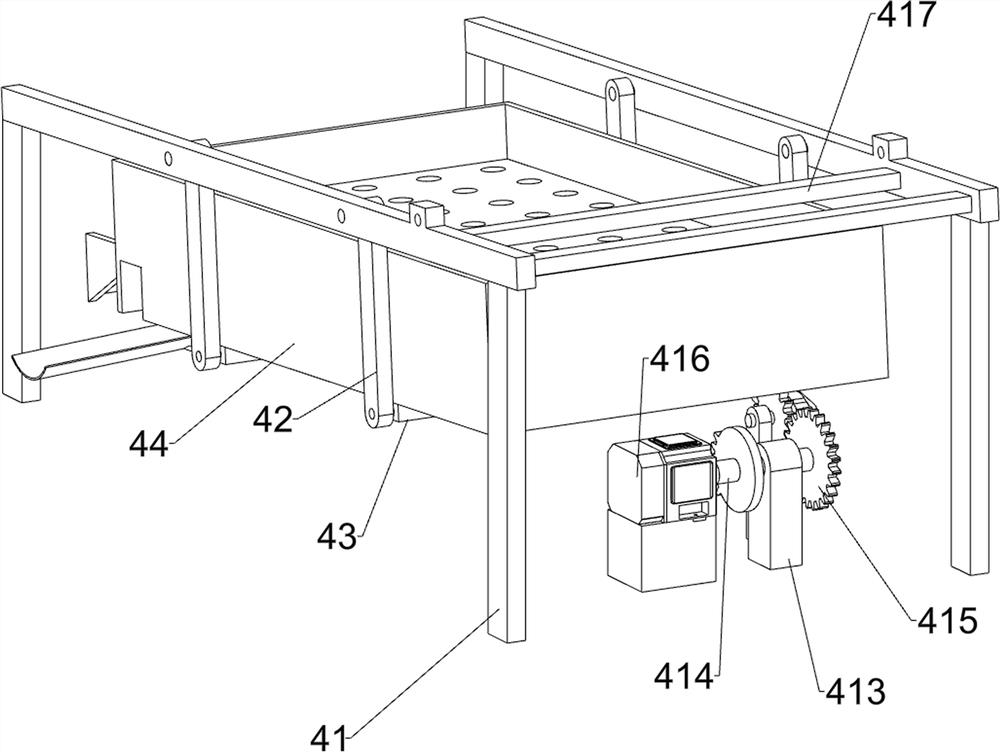

[0022] Such as Figure 1-4 As shown, a vibratory screening device for agricultural wool grains includes a base 1, a support column 2, a workbench 3, a screening mechanism 4 and a feeding mechanism 5, the base 1 is provided with a support column 2, and the support column 2 is provided with a working The table 3 and the workbench 3 are provided with a screening mechanism 4, and the upper right side of the screening mechanism 4 is provided with a blanking mechanism 5.

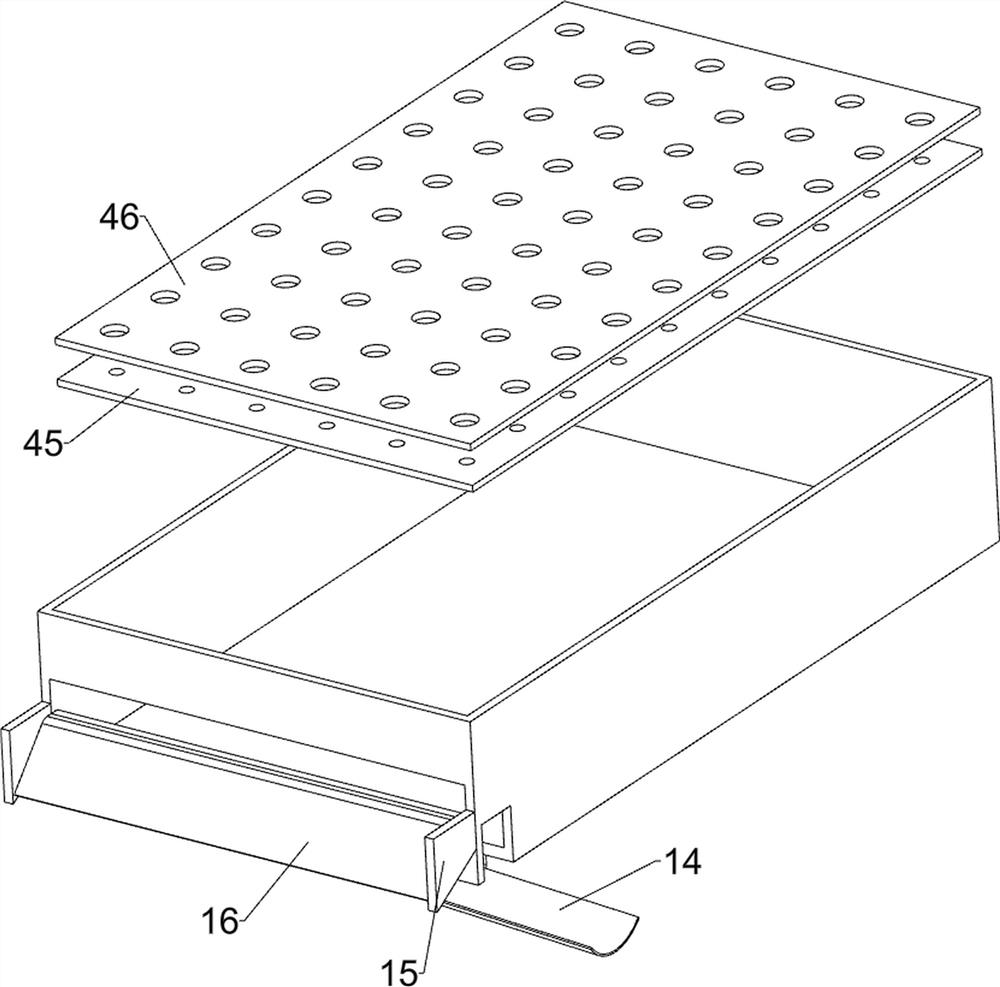

[0023] The screening mechanism 4 includes a bracket 41, a first connecting rod 42, a pad rod 43, a box body 44, a fine sieve plate 45, a coarse sieve plate 46, a sector block 47, a first bearing seat 48, a first transmission shaft 49, and a cam 410 , the second connecting rod 411, the first circular gear 412, the second bearing seat 413, the second transmission shaft 414, the second circular gear 415, the servo motor 416 and the connecting rod 417, and the workbench 3 is symmetrical about the center line of the wo...

Embodiment 2

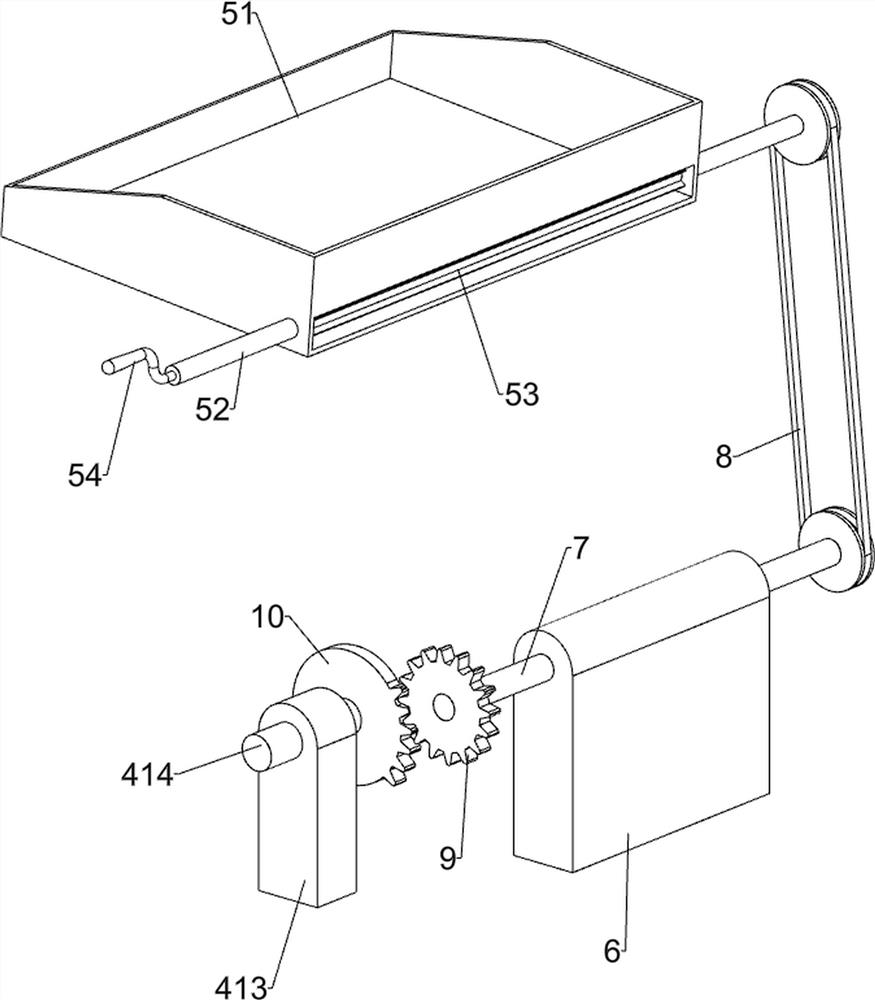

[0027] Such as Figure 5 Shown, on the basis of embodiment 1, a kind of vibratory screening device for agricultural wool grain also includes the 3rd bearing block 6, the 3rd transmission shaft 7, belt drive 8 and the 3rd round gear 9, missing gear 10, On the workbench 3, a third bearing seat 6 is arranged on the right side, and a third transmission shaft 7 is arranged in rotation in the third bearing seat 6. A belt transmission device 8 is arranged between the front end of the third transmission shaft 7 and the front part of the rotating shaft 52. The rear end of the three transmission shafts 7 is provided with a third round gear 9 , and the front end of the second transmission shaft 414 is provided with a missing gear 10 , and the missing gear 10 cooperates with the third round gear 9 .

[0028] In the process that the second transmission shaft 414 rotates, the rotation of the second transmission shaft 414 will drive the missing gear 10 to rotate, and when the screening mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com