Screening, weighing, sorting and packaging device applied to sheet product assembly line

A technology for sheet products and packaging equipment, applied in packaging, sorting, packaging protection, etc., can solve problems such as slow efficiency, high cost, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0051] The sheet product mentioned in this application scheme refers to the small packaging products of rectangular, square, and circular sheet quantitatively filled in various industries such as food, medicine, and cosmetics;

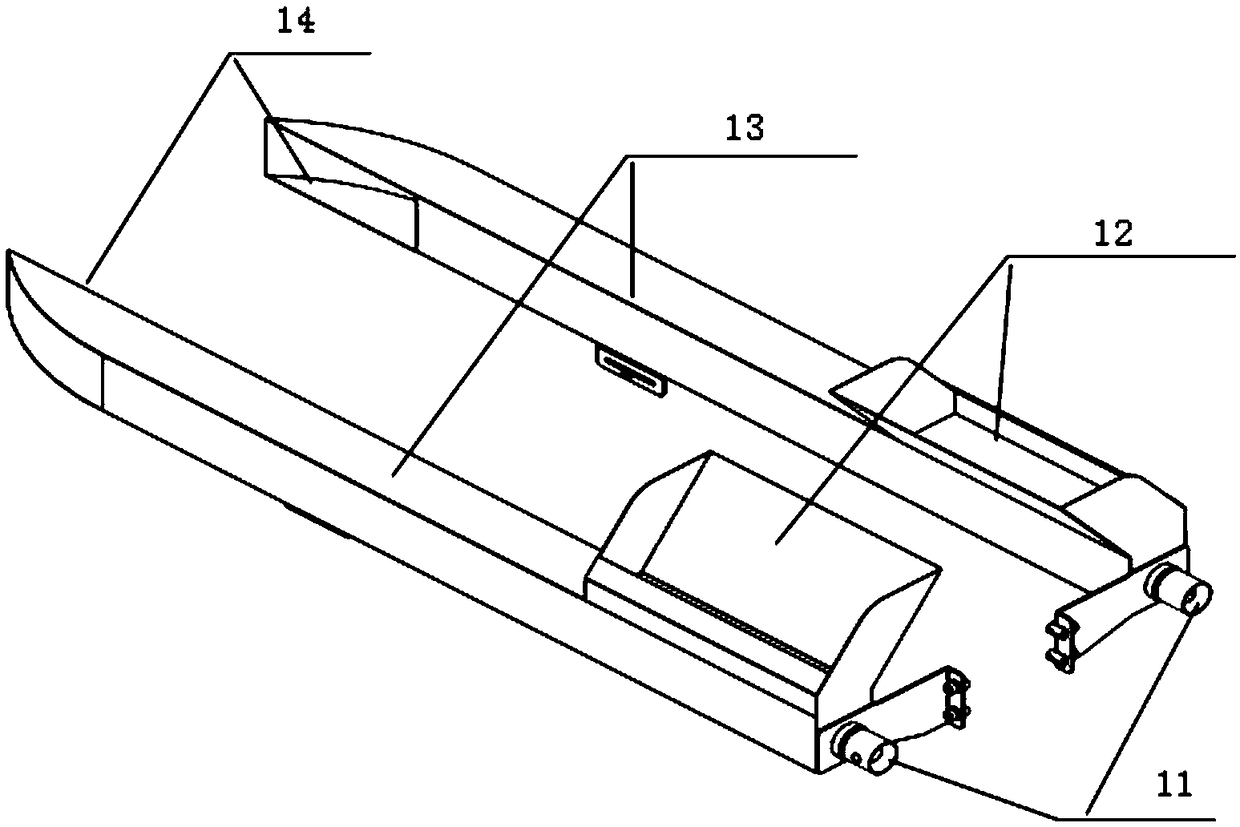

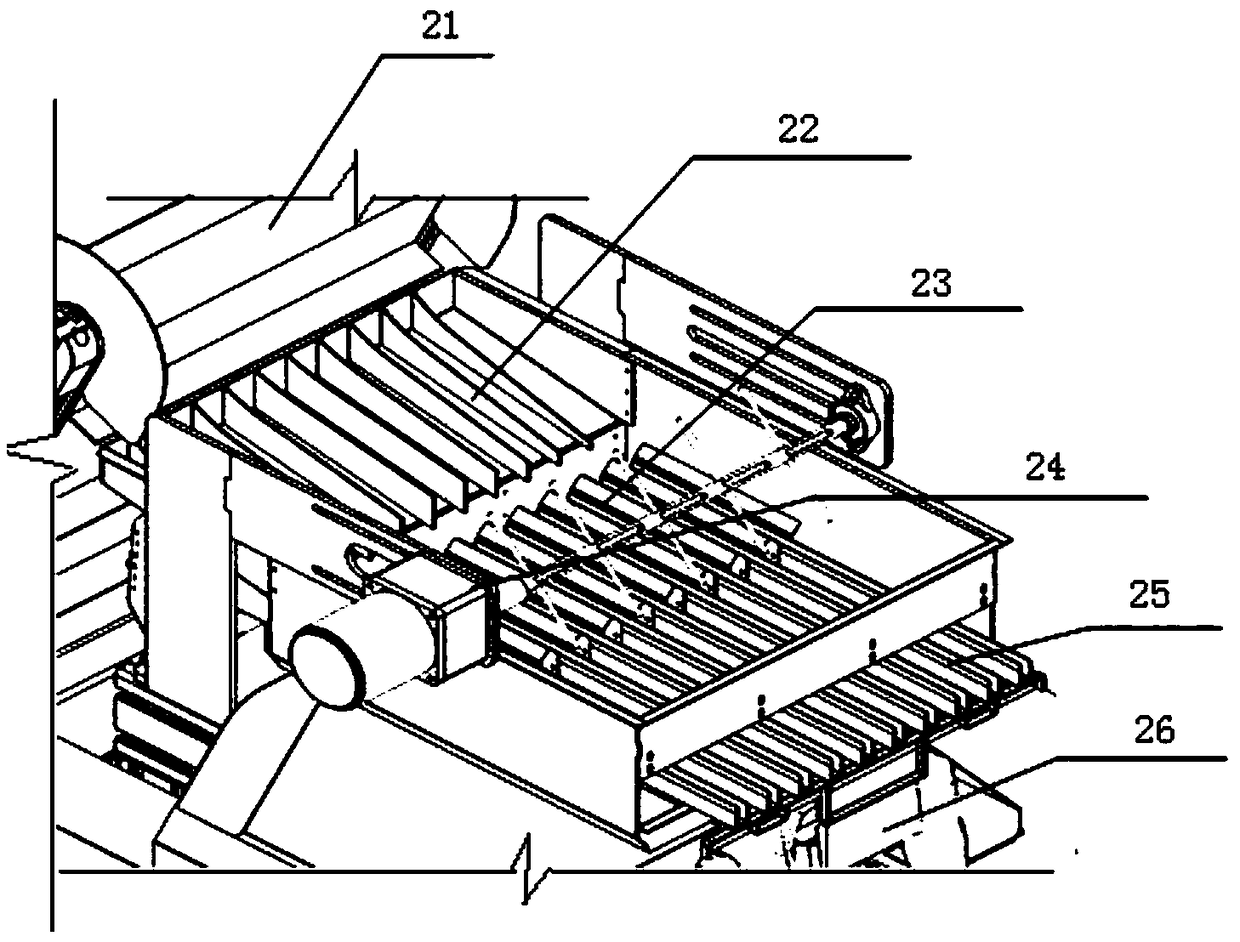

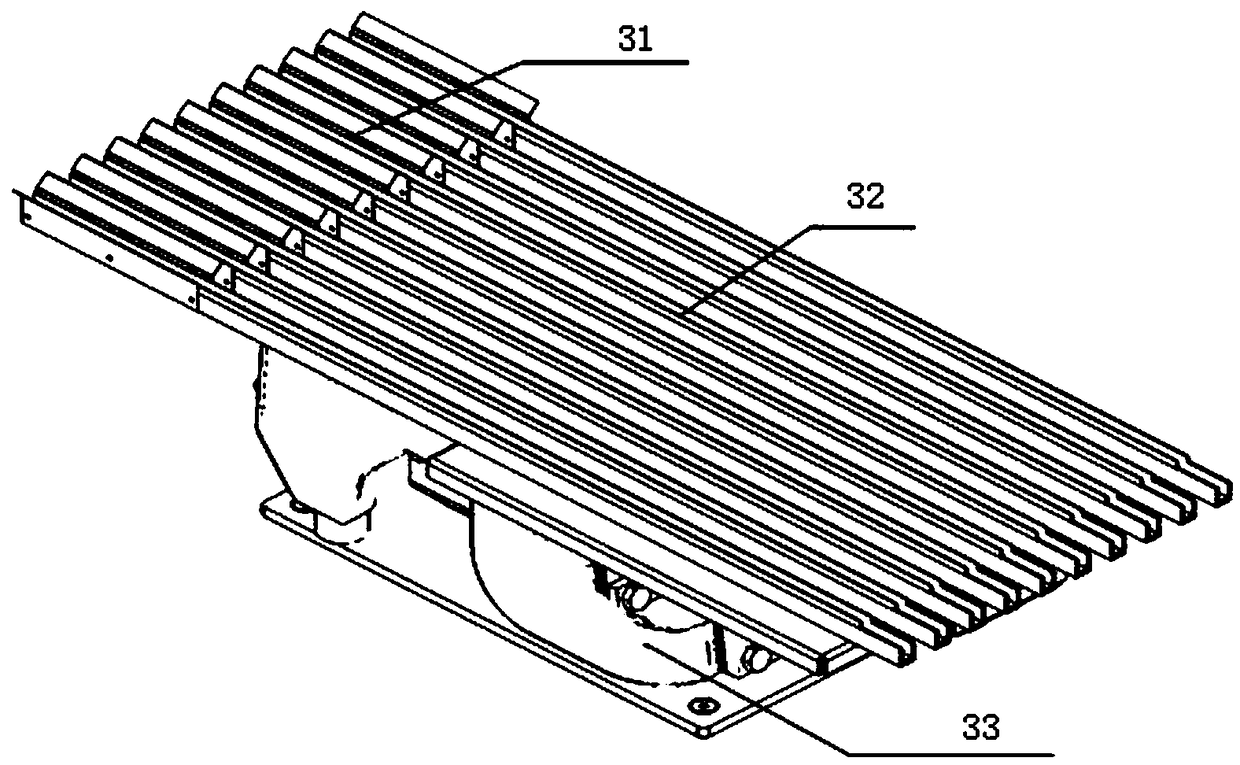

[0052] Including residual material recovery device 1, raw material screening device 2, material vibration arrangement and conveying device 3, automatic separation and separation device for raw materials and products 4, automatic weighing and rejecting device, automatic storage buffer device 5, automatic counting and stacking device 6, automatic buffering and unloading port 7;

[0053] The residual material recovery device 1 is installed on the assembly line. Above the residual material recovery device 1 is a raw material screening device 2. One side of the raw material screening device 2 is a raw material vibration arrangement c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com