A kind of screening equipment dedicated to construction sand and gravel

A technology for screening equipment and sand and gravel, which is applied in the fields of screening, cleaning methods and utensils, and cleaning methods using tools, etc., can solve the problems of uneven screening, affecting construction projects, time-consuming and laborious, etc., and achieves low manufacturing cost and convenient use. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

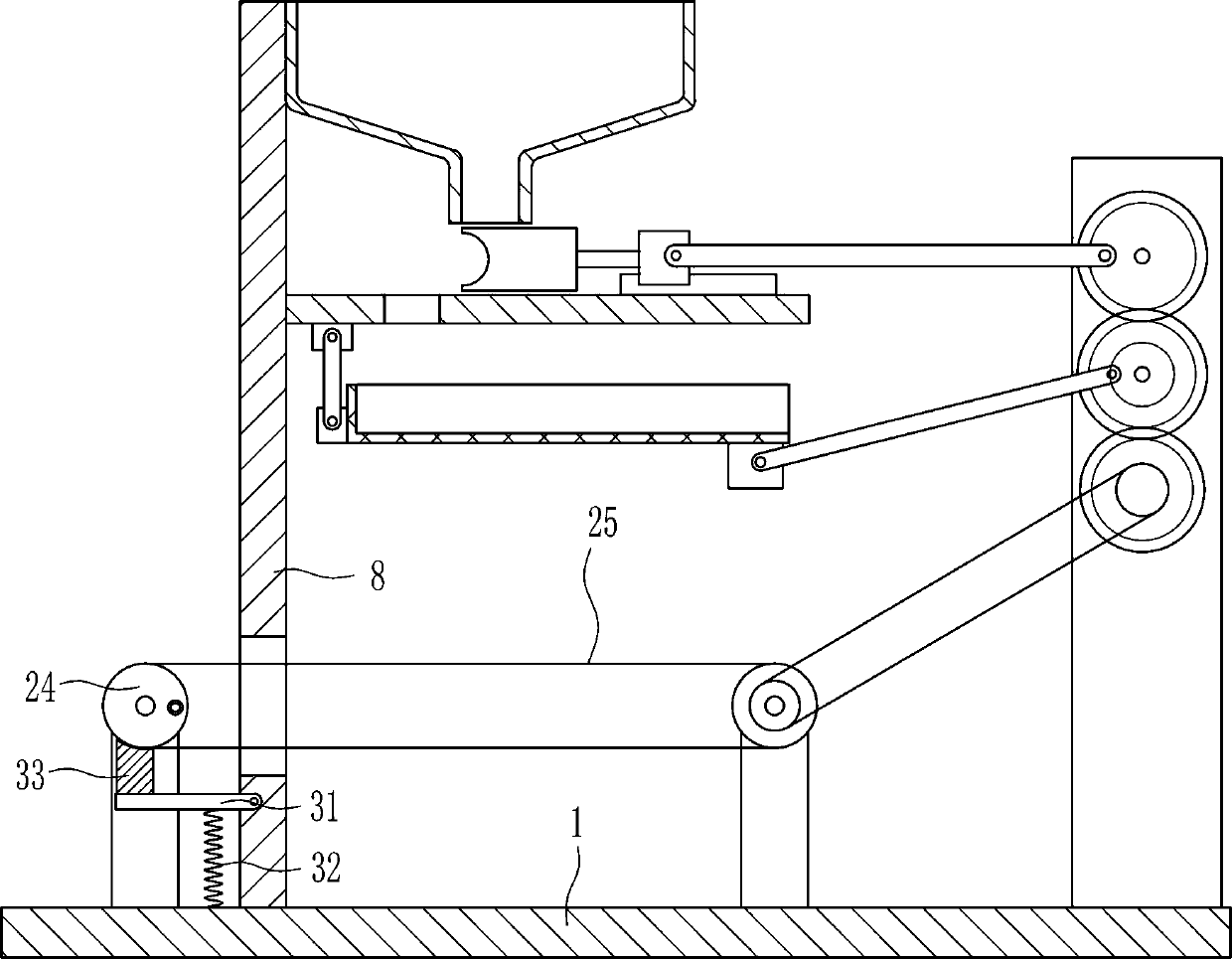

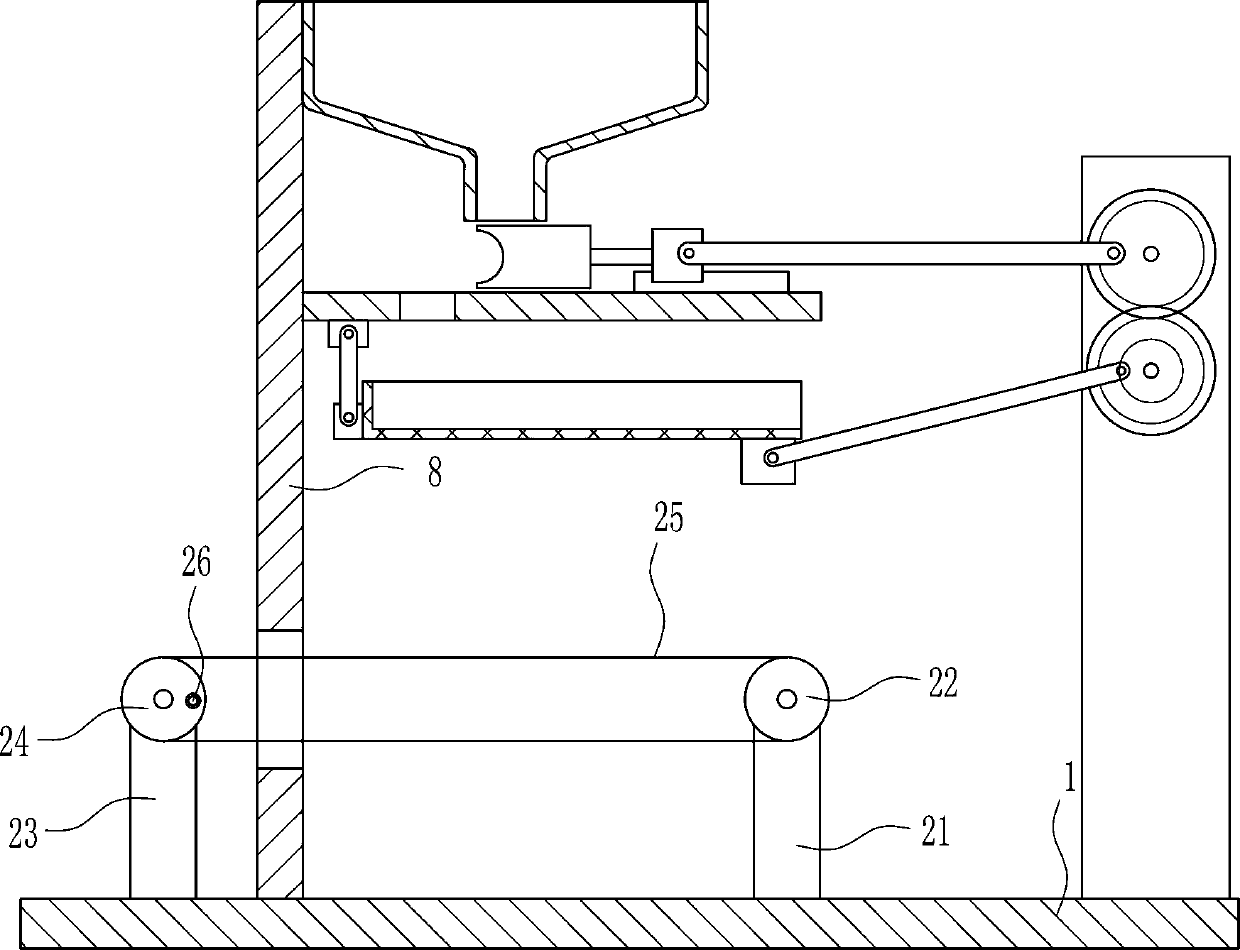

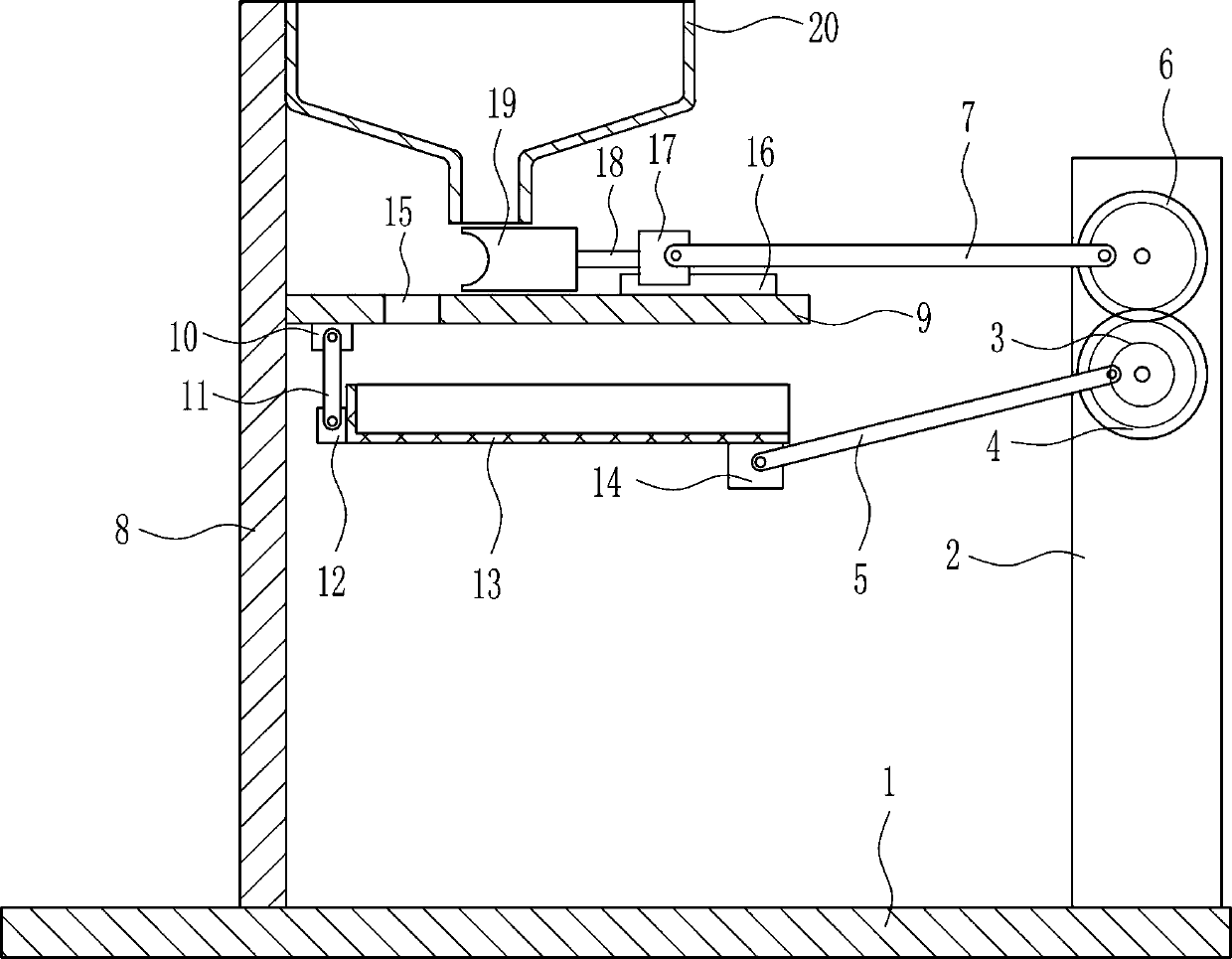

[0024] A kind of screening equipment dedicated to construction sand and gravel, such as Figure 1-5As shown, it includes a base 1, a first fixed plate 2, a first motor 3, a first gear 4, a first connecting rod 5, a second gear 6, a second connecting rod 7, a first bracket 8, and a second bracket 9 , the first fixed block 10, the third connecting rod 11, the second fixed block 12, the screen 13, the third fixed block 14, the slide rail 16, the slide block 17, the first pole 18, the push plate 19 and the funnel 20, A first fixed plate 2 is fixedly connected to the upper right side of the base 1, a first motor 3 is fixedly connected to the upper front side of the first fixed plate 2, and a first gear 4 is fixedly connected to the output shaft of the first motor 3. A second gear 6 is rotatably connected to the upper front side of the first fixed plate 2. The second gear 6 is located above the first motor 3. The second gear 6 meshes with the first gear 4. On the front side of the f...

Embodiment 2

[0026] A kind of screening equipment dedicated to construction sand and gravel, such as Figure 1-5 As shown, it includes a base 1, a first fixed plate 2, a first motor 3, a first gear 4, a first connecting rod 5, a second gear 6, a second connecting rod 7, a first bracket 8, and a second bracket 9 , the first fixed block 10, the third connecting rod 11, the second fixed block 12, the screen 13, the third fixed block 14, the slide rail 16, the slide block 17, the first pole 18, the push plate 19 and the funnel 20, A first fixed plate 2 is fixedly connected to the upper right side of the base 1, a first motor 3 is fixedly connected to the upper front side of the first fixed plate 2, and a first gear 4 is fixedly connected to the output shaft of the first motor 3. A second gear 6 is rotatably connected to the upper front side of the first fixed plate 2. The second gear 6 is located above the first motor 3. The second gear 6 meshes with the first gear 4. On the front side of the ...

Embodiment 3

[0029] A kind of screening equipment dedicated to construction sand and gravel, such as Figure 1-5 As shown, it includes a base 1, a first fixed plate 2, a first motor 3, a first gear 4, a first connecting rod 5, a second gear 6, a second connecting rod 7, a first bracket 8, and a second bracket 9 , the first fixed block 10, the third connecting rod 11, the second fixed block 12, the screen 13, the third fixed block 14, the slide rail 16, the slide block 17, the first pole 18, the push plate 19 and the funnel 20, A first fixed plate 2 is fixedly connected to the upper right side of the base 1, a first motor 3 is fixedly connected to the upper front side of the first fixed plate 2, and a first gear 4 is fixedly connected to the output shaft of the first motor 3. A second gear 6 is rotatably connected to the upper front side of the first fixed plate 2. The second gear 6 is located above the first motor 3. The second gear 6 meshes with the first gear 4. On the front side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com