Steam cooking device and humidity control method

A technology of humidity control and cooking device, which is applied to steam cooking utensils, measuring devices, timing control ignition mechanisms, etc., can solve the problems of inaccurate humidity control, high humidity of the inner tank and overshoot, etc., to solve the problems of inaccurate humidity control and guarantee Accuracy and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

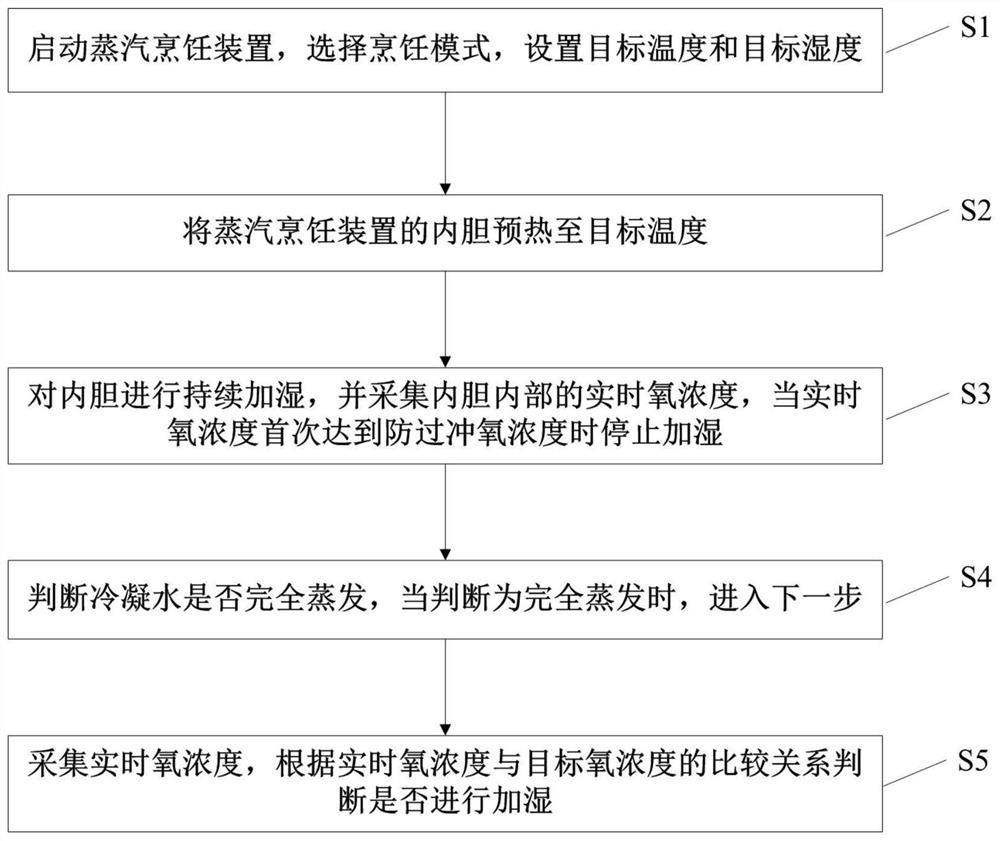

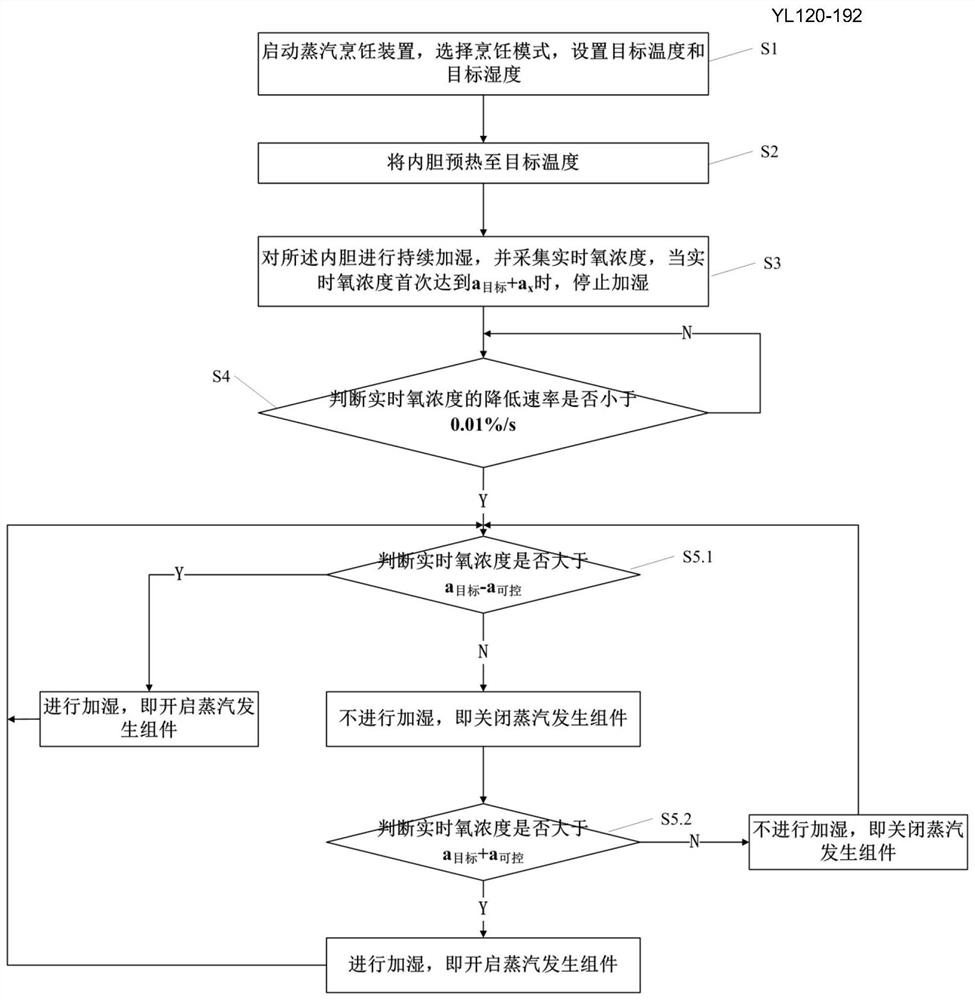

[0052] This embodiment provides a humidity control method for steam cooking devices, such as figure 1 shown, including the following steps:

[0053] S1, start the steam cooking device, select the cooking mode, set the target temperature and target humidity;

[0054] S2, preheating the inner container of the cooking device to the target temperature;

[0055] S3, continuously humidify the inner tank, and collect the real-time oxygen concentration inside it, and stop humidifying when the real-time oxygen concentration reaches the anti-overshoot oxygen concentration for the first time;

[0056] Wherein, the anti-overshoot oxygen concentration is obtained according to the target humidity and the condensed water produced during the preheating process;

[0057] S4, judging whether the condensed water is completely evaporated, and when it is judged to be completely evaporated, go to S5;

[0058] S5, collect the real-time oxygen concentration, and judge whether to perform humidifica...

Embodiment 2

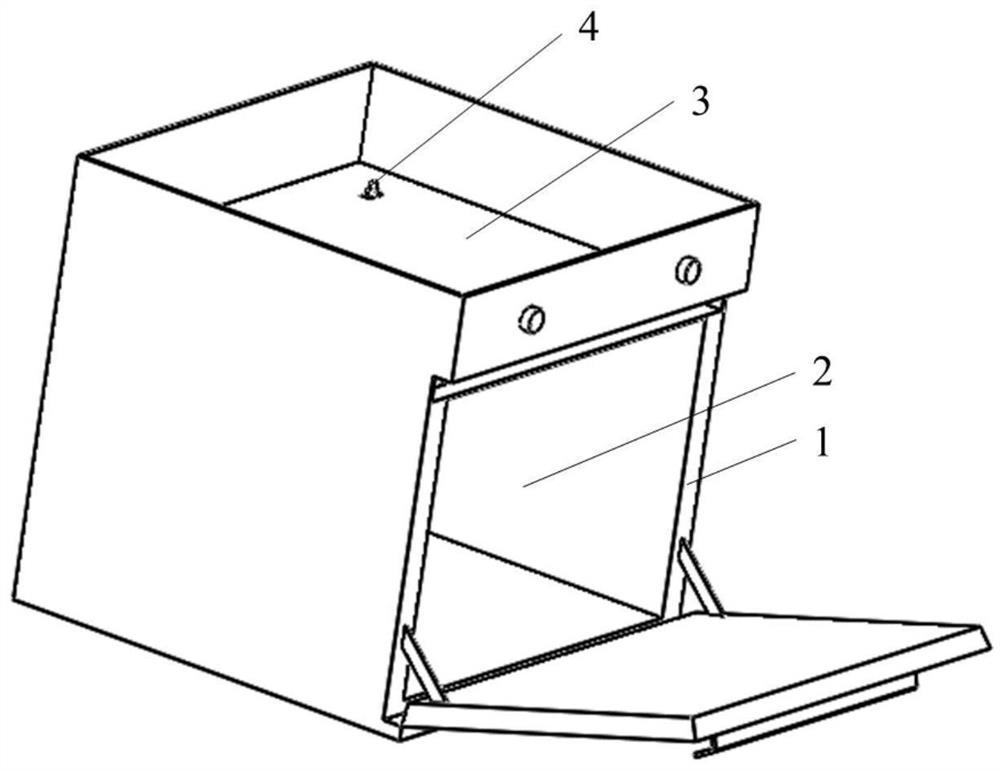

[0127] This embodiment provides a steam cooking device, using the above humidity control method, such as image 3 and Figure 4 As shown, the steam cooking device includes a housing 1, an inner tank 2, a middle plate 3 and an oxygen concentration detection assembly 4, the inner tank 2 is arranged in the housing 1, and the middle board 3 is located in the inner tank 2, the oxygen concentration detection component 4 is detachably arranged on the middle plate 3, and the top of the oxygen concentration detection component 4 protrudes into the inner tank 2.

[0128] In this way, the oxygen concentration detection assembly 4 is arranged on the middle plate 3, and the top of the oxygen concentration detection assembly 4 is inserted into the inner container 2, that is, the head for detecting the oxygen concentration is inserted into the inner container 2, The assembly and disassembly of the oxygen concentration detection component 4 is facilitated.

[0129] At the same time, the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com