Pressure transmitter convenient to disassemble and assemble

A transmitter and pressure technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of general sealing effect, inconvenient disassembly, corrosion, etc., and achieve the effect of easy detection of pipelines, good sealing effect, and avoiding rust prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

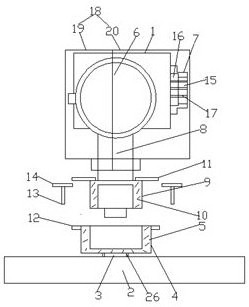

[0022] Example 1 as Figure 1-2 As shown, a pressure transmitter that is easy to assemble and disassemble according to an embodiment of the present invention includes a pressure transmitter body 1 and a pipe 2, and the top end of the pipe 2 is provided with a welded connecting pipe 3, and the connecting pipe 3 The inside communicates with the inside of the pressure transmitter body 1, the outer wall of the connecting pipe 3 is fixed with a hollow first fixed sleeve 4, the top of the first fixed sleeve 4 is an open end, and the first fixed sleeve 4 The inner wall is fixed with a first sealing rubber ring 5, the side wall of the pressure transmitter body 1 is respectively provided with an instrument panel 6 and a line joint 7, and the lower end side wall of the pressure transmitter body 1 is fixedly connected with a mounting Rod 8, the side wall of the installation rod 8 is provided with a through hole, the through hole communicates with the pressure transmitter body 1, and the ...

Embodiment 2

[0023] Embodiment 2 is on the basis of embodiment 1 such as figure 1 As shown, for the line connector 7, the side wall of the line connector 7 is provided with a line interface 15, and the line interface 15 is filled with a rubber plug 16, and the side wall of the rubber plug 16 is in contact with the The inner wall of the line interface 15 is slidably connected, the inner wall of the line interface 15 is provided with threads, and the side wall of the rubber plug 16 is provided with a plurality of threading holes 17 at equal intervals.

[0024] Through the above-mentioned scheme of the present invention, the beneficial effect is: through the line joint 7, the wire is passed through the threading hole 17 on the rubber plug 16, and is screwed on the line joint 7, which not only improves the sealing performance, but also effectively protects the line and avoids The wiring is damaged.

Embodiment 3

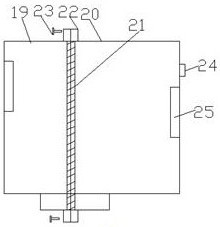

[0025] Embodiment 3 is such as on the basis of embodiment 1 Figure 1-2 As shown, for the pressure transmitter body 1, the pressure transmitter body 1 is covered with a plastic protective cover 18, and the pressure transmitter body 1 is divided into a left protective cover 19 and a right protective cover 20, The left protective cover 19 and the right protective cover 20 are spliced together, and the bottoms of the left protective cover 19 and the right protective cover 20 are respectively sleeved on the installation rod 8, and the left protective cover 19 and the right protective cover 20 Sealing strips 21 are fixed at the joints, and a mounting plate 22 is fixed on the left protective cover 19 and the right protective cover 20 , and a secondary plastic screw 23 is screwed on the mounting plate 22 .

[0026] Through the above scheme of the present invention, the beneficial effect is that the plastic protective cover 18 wraps the pressure transmitter body 1, so it plays a goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com