Direction-changeable centrifugal wind wheel and centrifugal fan thereof

A centrifugal wind wheel and direction changing technology, which is applied in the direction of mechanical equipment, non-variable pumps, radial flow pumps, etc., can solve the problems that are difficult to meet the requirements of modern homes, increase the volume of fans, etc., and achieve compact structure and low wind pressure loss. small, reduced size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

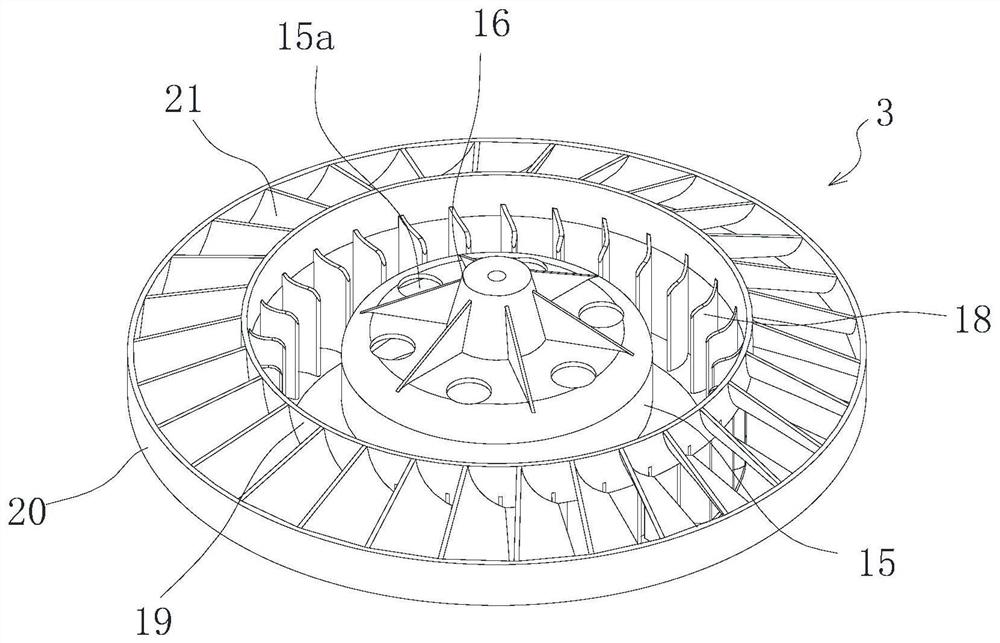

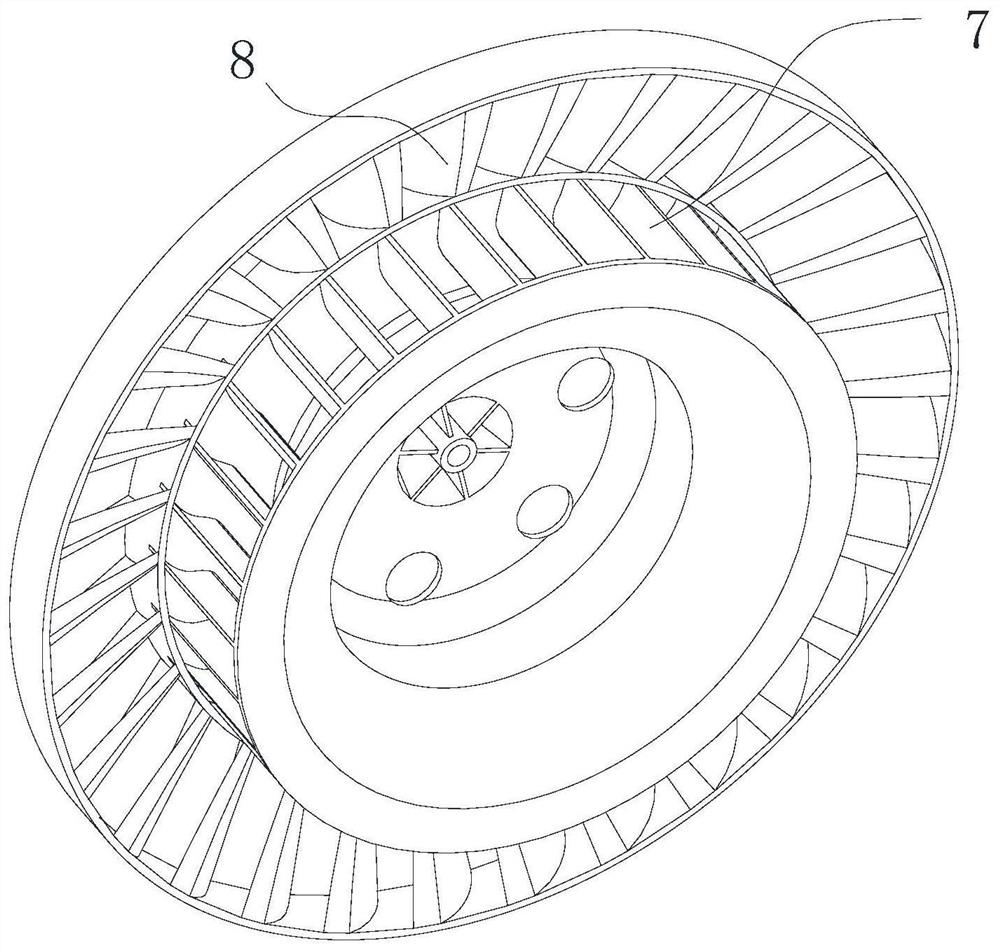

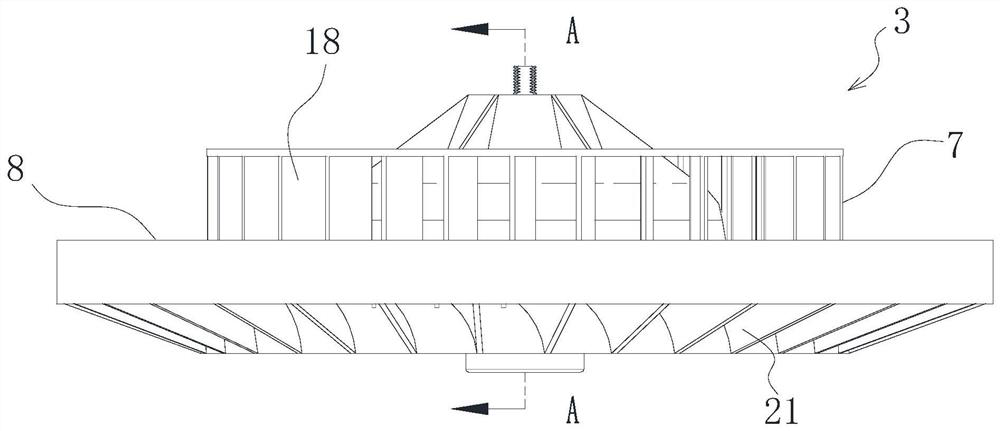

[0033] Such as figure 1 , figure 2 As shown, the direction-changing centrifugal wind wheel 3 of the present invention includes several blades, and the blades include air inlet blades 18 and air outlet blades 21, and several air inlet blades 18 form the air inlet impeller assembly 7, and several air outlet blades 21 The air outlet impeller assembly 8 is formed, the air inlet blade 18 is arranged axially, the air outlet blade 21 is arranged along the circumference of the air outlet impeller assembly 8, and the air outlet side of the air inlet blade 18 corresponds to the outlet blade 21 Intake side.

[0034] In this embodiment, the air outlet impeller assembly 8 is located at the upper end of the air inlet impeller assembly 7, and the air inlet impeller assembly 7 is in a cylindrical shape. Located on the outer wall of the inlet impeller assembly 7 , the outlet impeller assembly 8 is in the shape of a disc inclined downward. In principle, the acute angle α between the air inl...

Embodiment 2

[0039] Such as image 3 , Figure 4 As shown, the difference between this embodiment and Embodiment 1 is: in this embodiment, the air outlet impeller assembly 8 is located at the lower end of the air inlet impeller assembly 7, and at the same time, the air outlet impeller assembly 8 is in the shape of an upwardly inclined disc .

[0040] The wind rotor of this embodiment can realize wind inlet and outlet from different sides on the basis of not needing additional air ducts.

Embodiment 3

[0042] Such as Figure 5 , Figure 6 and Figure 7 As shown, the centrifugal fan of this embodiment uses the centrifugal fan wheel of Embodiment 1. It specifically includes: a fan housing 1, the motor 2 is arranged in the fan housing 1, the output shaft of the motor 2 is connected with the wind wheel 3, the top of the fan housing 1 is open, and the top of the fan housing 1 There is an air inlet isolation cover 4, and the top of the fan casing 1 is provided with a cover plate 1a, which is used to connect with the air inlet isolation cover 4, or to facilitate connection with the ceiling or decorative panels when installing a bathroom heater. The air inlet isolation cover 4 has An air inlet 5, an air outlet 6 is formed between the outer wall of the air inlet isolation cover 4 and the top of the fan casing 1, and the wind wheel 3 includes an air inlet impeller assembly 7 and an air outlet impeller assembly 8, and the air inlet of the air inlet impeller assembly 7 The side corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com