Two-stage adjusting system suitable for intermediate adjusting valve to participate in adjusting and lifting industrial steam supply parameters

A technology for steam supply parameters and adjustment systems, applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve the problems of medium pressure valve vibration, sudden closing, etc., to improve heat supply flow and pressure, low renovation cost, flow Field stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

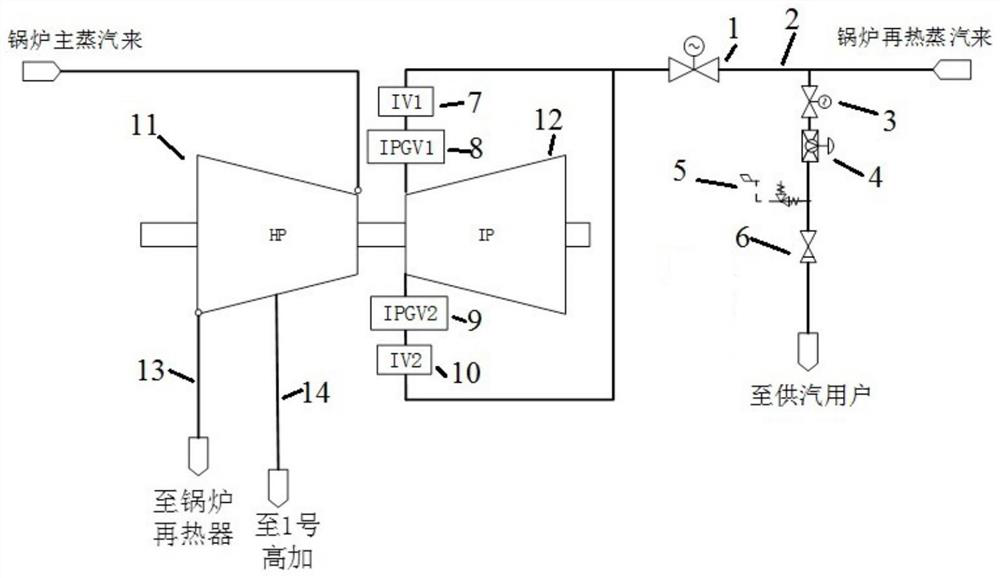

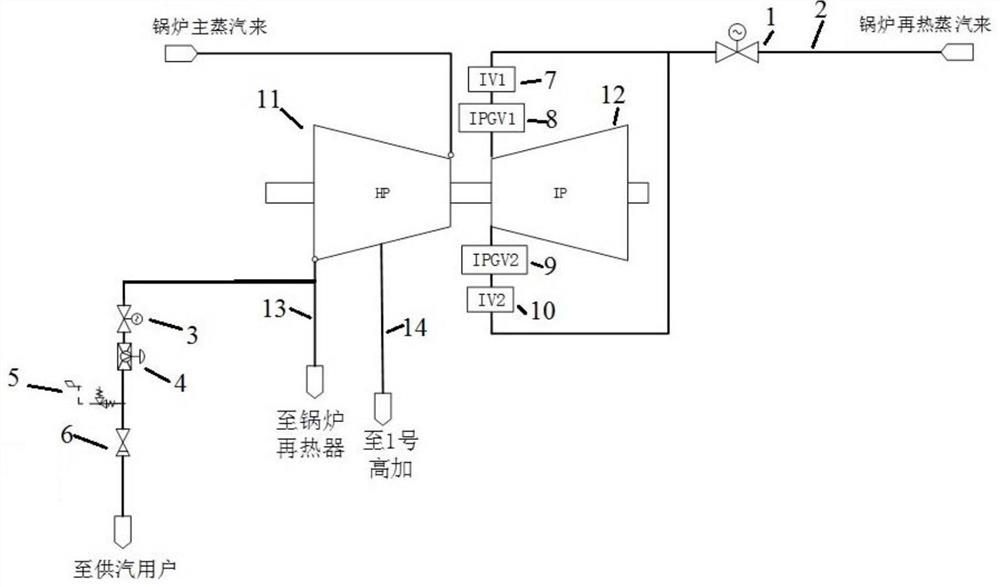

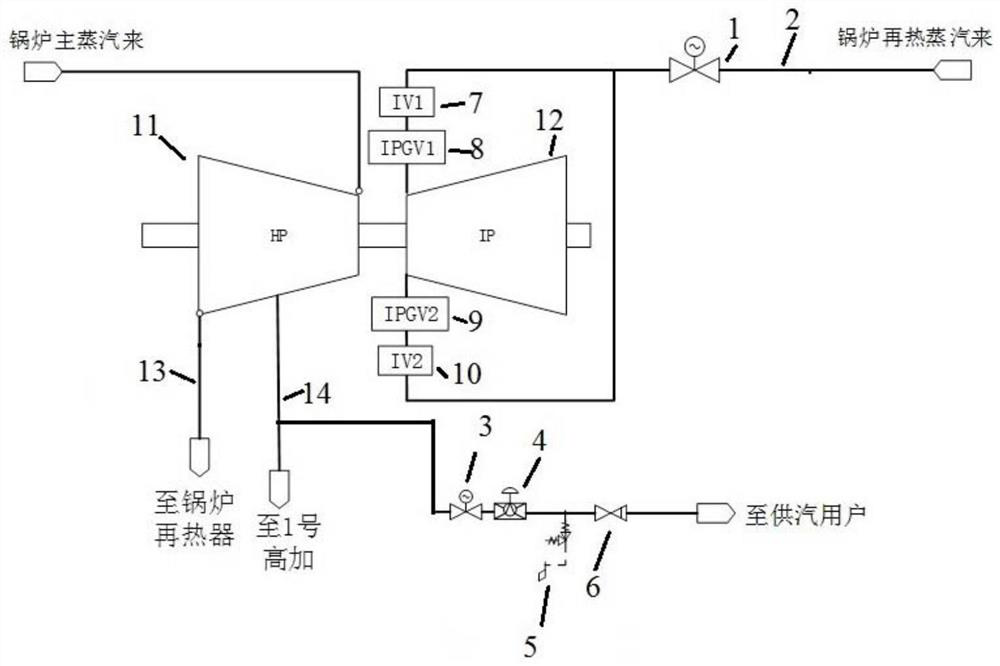

[0023] refer to figure 1 , the two-stage adjustment system suitable for the middle regulating valve to participate in the adjustment and improvement of industrial steam supply parameters described in the present invention includes a boiler reheat steam pipeline 2, a regulating butterfly valve 1, a first medium pressure main steam valve 7, a first medium pressure regulating Valve 8, second medium pressure main steam valve 10, second medium pressure regulating valve 9, high pressure cylinder 11, medium pressure cylinder 12, boiler main steam pipeline, cold reheat pipeline 13 and steam extraction pipeline 14; boiler reheat steam pipeline 2 After the adjustable butterfly valve 1, it is divided into two paths, one of which is connected to the first inlet of the medium pressure cylinder 12 through the first medium pressure main steam valve 7 and the first medium pressure reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com