A method of using high-pressure water jets to induce the overall destruction of overlying residual coal pillars

A technology of high-pressure water jet and residual coal, which is applied in earth square drilling, ground mining, mining equipment, etc., can solve the problems of unfavorable mine safety and high efficiency, economical production, inability to destroy the overall coal pillars left behind, and hidden safety hazards, etc., to achieve convenience The effect of on-site implementation, wide application range, and small amount of on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

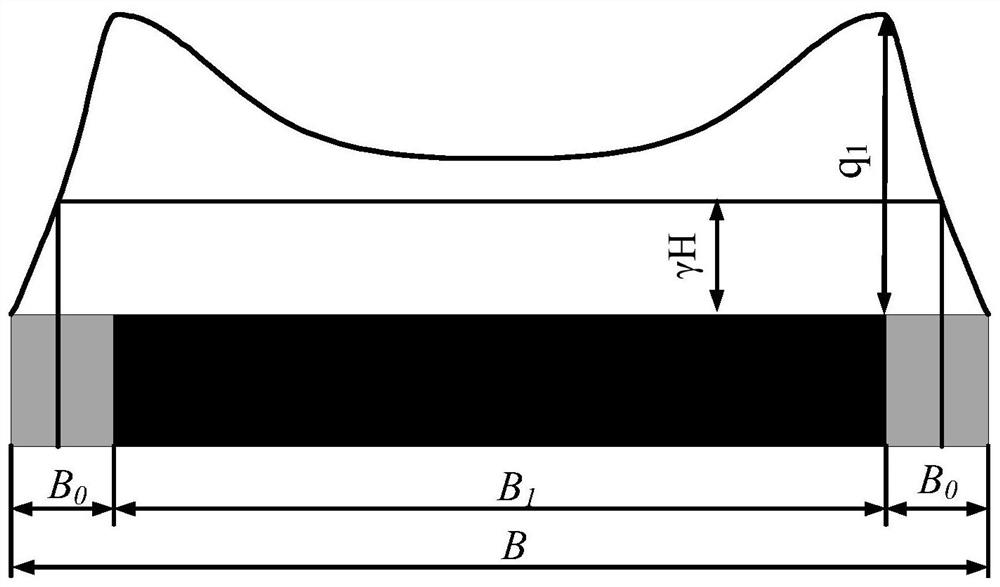

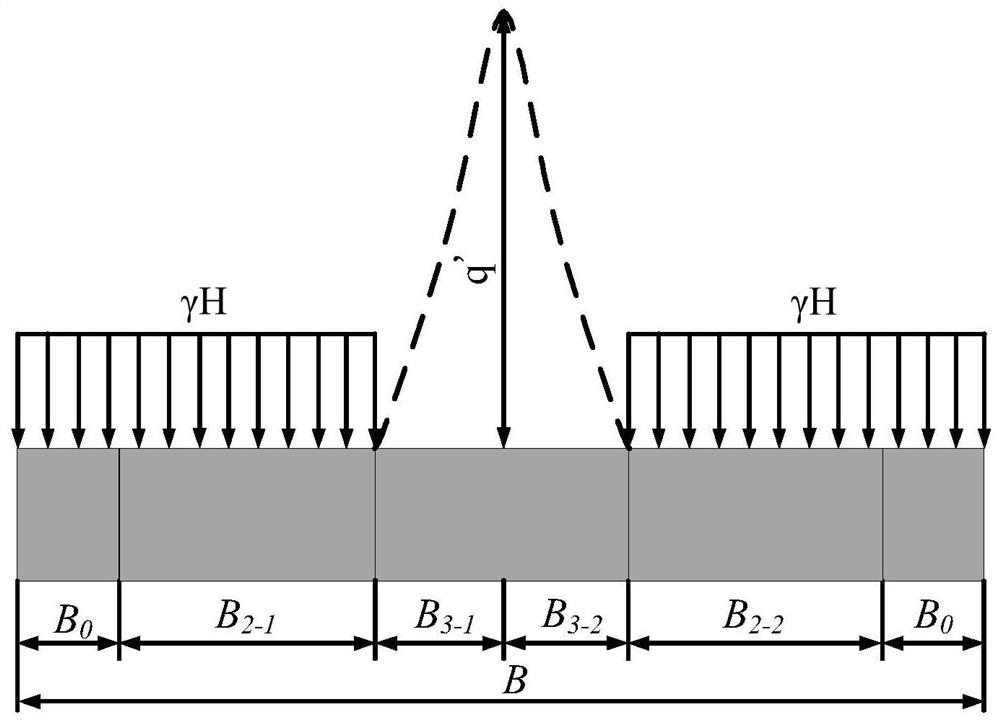

[0080] Taking a coal mine as an example, the working face 3 of the lower coal seam is 2540m long, 180m wide, with an average buried depth of 400m, an average coal thickness of 5.0m, and an average coal seam inclination of 2°. In the gob area of face 2, the average spacing is 25m. The residual coal pillar 1 between the upper coal seam working face 2 is located above the lower coal seam working face 3. The width B of the residual coal pillar 1 is 38m. The distance between the residual coal pillar 1 and the lower coal seam working face The horizontal distance of mining roadway 4 is 30m, and the height of mining roadway 4 in the lower coal seam working face is 5m and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com