Quick screwing-on and screwing-off drill rod with connector convenient to disassemble and assemble

A drill pipe, fast technology, applied in drill pipe, drill pipe, drilling equipment and other directions, can solve the problems of short joint undercut risk and labor intensity, aggravate drill pipe surface friction, affect the strength of drill pipe joints, etc. Maintenance cost and maintenance period, good engineering value, effect of reducing lateral vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

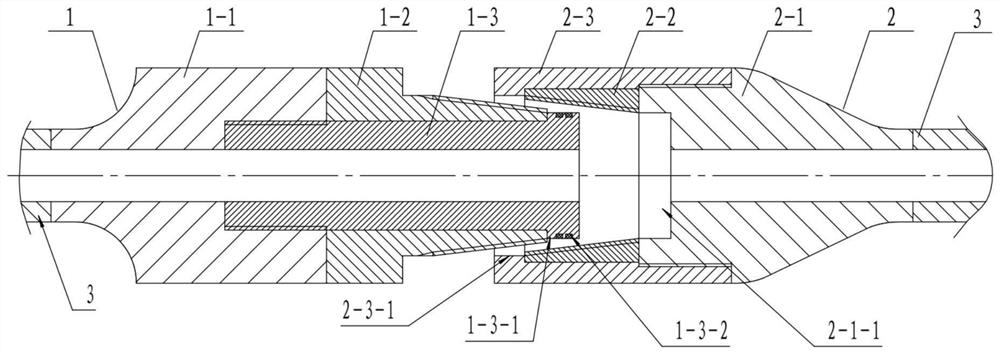

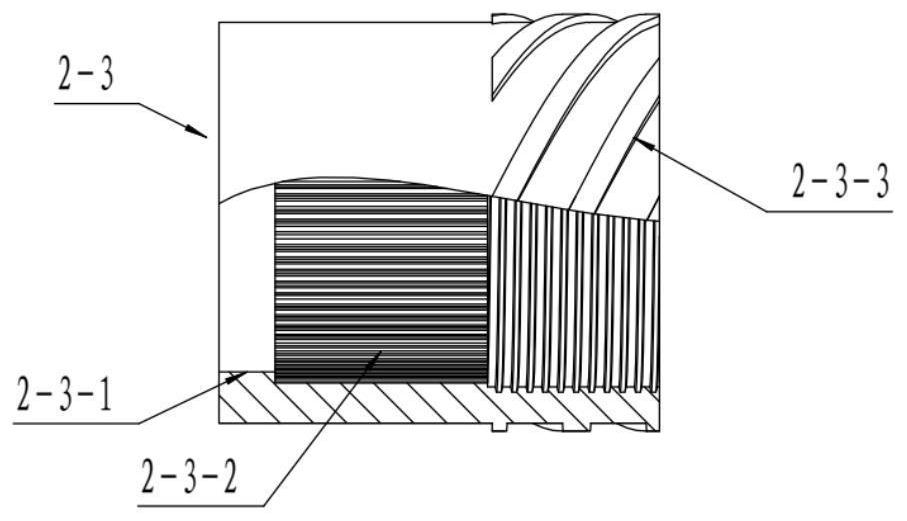

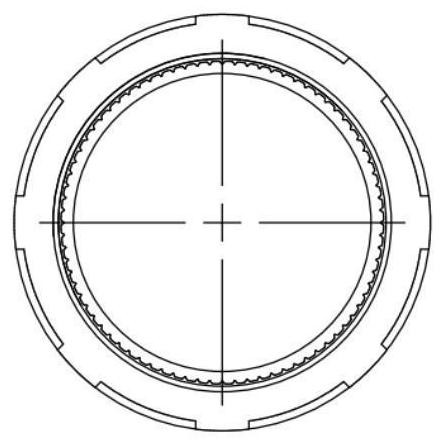

[0021] see figure 1 , the present invention includes a rod body 3, a male joint 1 and a female joint 2, and one end of the male joint and the female joint is respectively connected to the rod body 3. The male joint and the female joint of the present invention respectively include three main parts. The male connector is composed of a male connector body 1-1, a male connector threaded section 1-2 and a male connector connecting section 1-3. The small end of the male joint body is friction-welded with the rod body 3, and the male joint body is provided with a through hole matching the rod body. The threaded section of the male joint is a connecting part for connecting the female joint, and the function of the connecting section of the male joint is to connect the threaded section of the male joint with the main body of the male joint. The threaded section of the male joint is a hollow structure. The connecting section of the male joint passes through the inner hole of the thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com