Safety device for high-altitude installation of steel structure workshop

A safety device and steel structure technology, applied in building construction, building material processing, construction, etc., can solve problems such as hidden safety hazards, long and narrow moving space for workers, and difficult positioning of safety hooks, reducing swing amplitude and improving stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

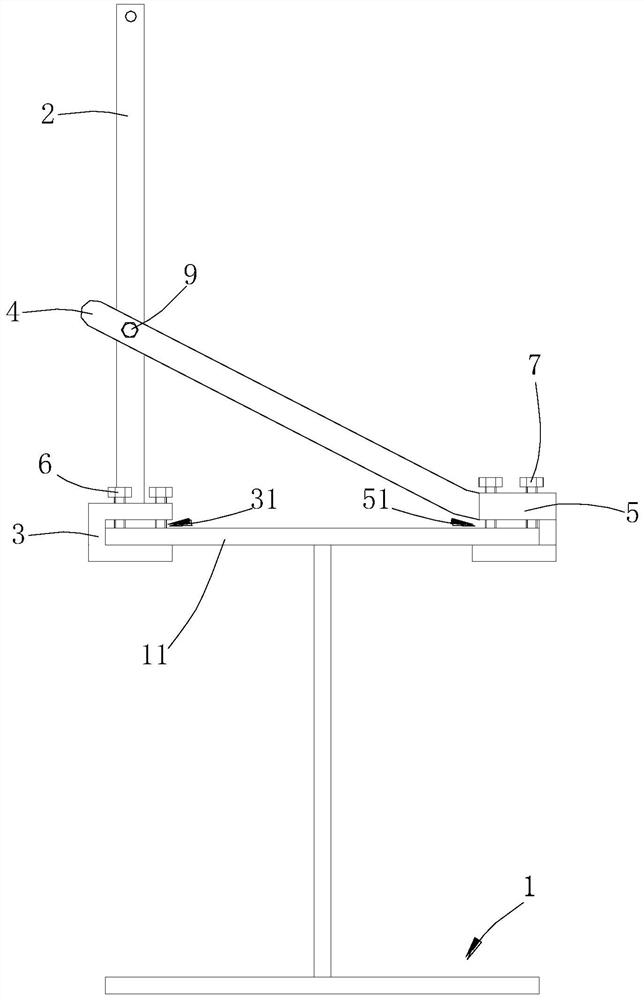

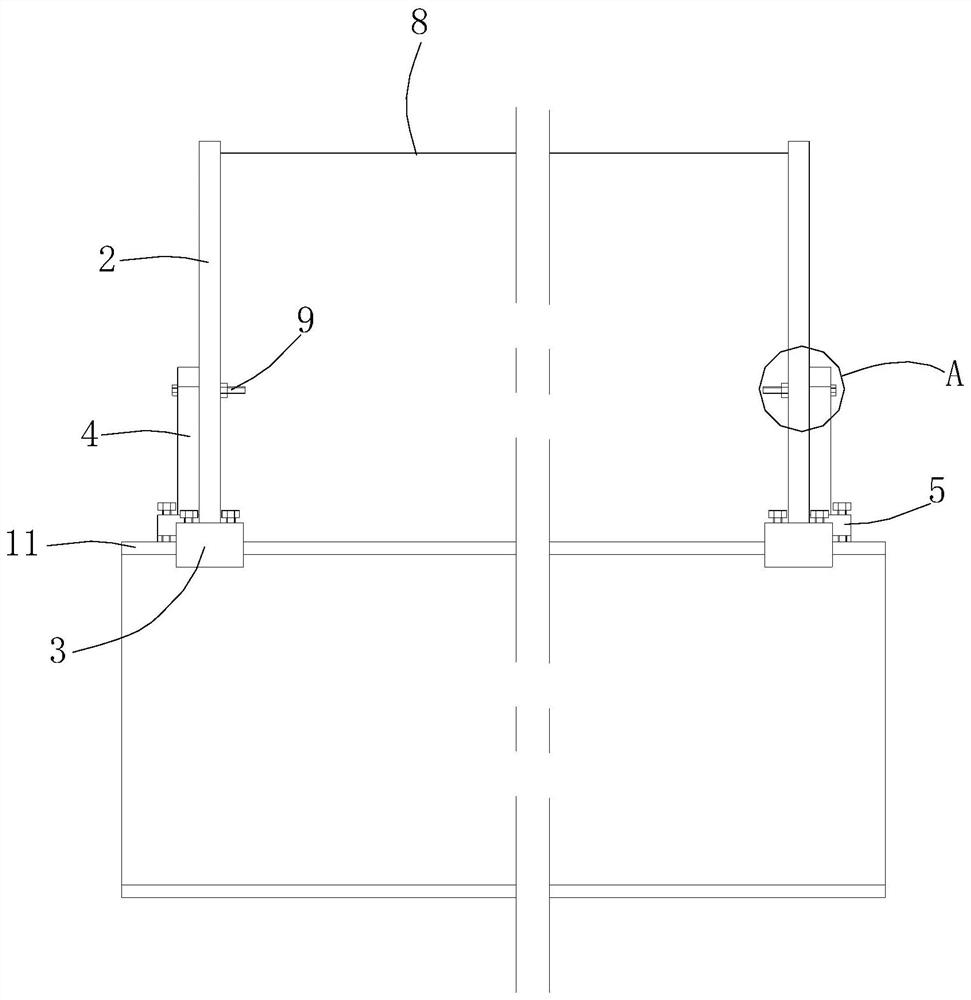

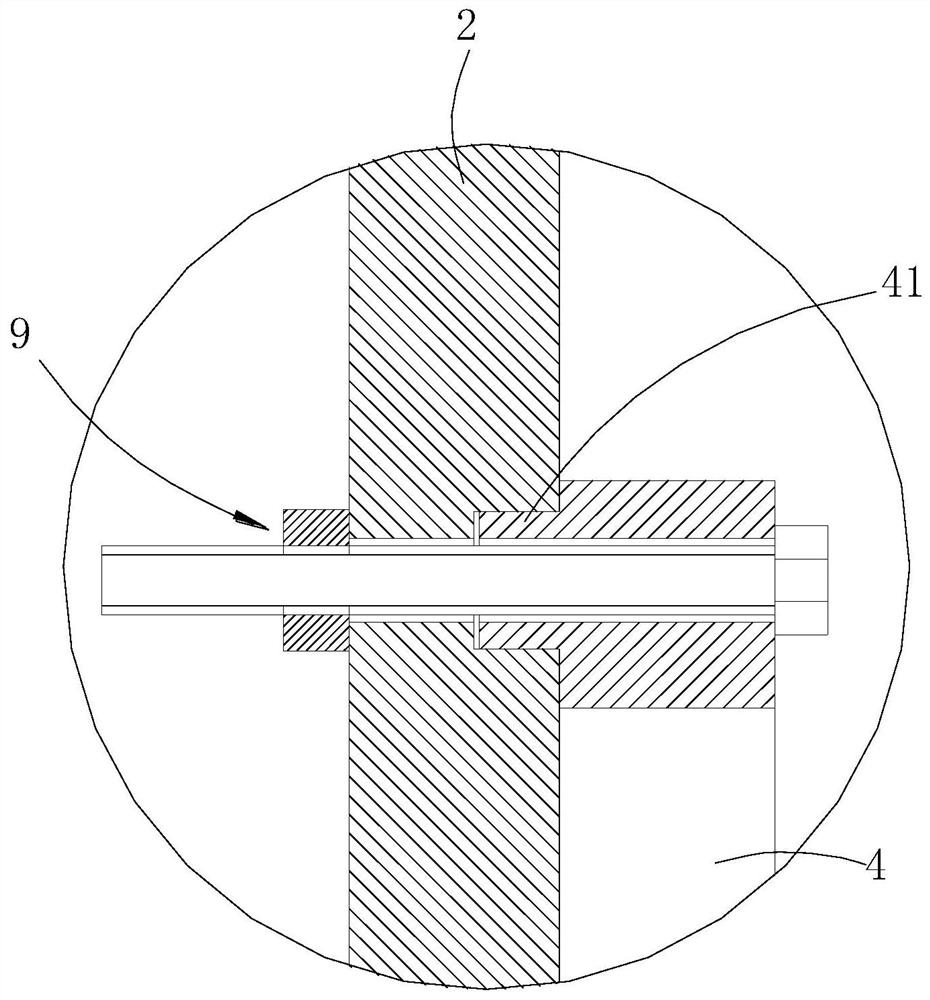

[0020] Such as Figures 1 to 3 shown

[0021] This safety device comprises fixed wire rope 8 and two groups of fixed components.

[0022] Two sets of fixing assemblies are respectively distributed on the flange plates 11 on both sides of the steel beam 1 in the longitudinal direction, and each set of fixing assemblies includes a fixing rod 2 , a first engaging block 3 , a second engaging block 5 and an oblique support rod 4 .

[0023] The lower end of the fixing rod 2 is welded on the first engaging block 3, and the left side wall of the first engaging block 3 has a first engaging groove 31 matching with the flange plate 11;

[0024] The lower end of the oblique support rod 4 is connected to the upper end surface of the second engaging block 5, and the right side wall of the second engaging block 5 is provided with a second card slot 51 that cooperates with the flange plate 11, and the upper end of the oblique supporting rod 4 obliquely extends toward the fixed rod 2 directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com