Anti-thread-loose type spinning processing device used for flax textile device

A processing device and thread-prevention technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problem that the spinning thread affects the normal use of the textile device, consumes time, and cannot adjust the position of the spinning thread. Applicable and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

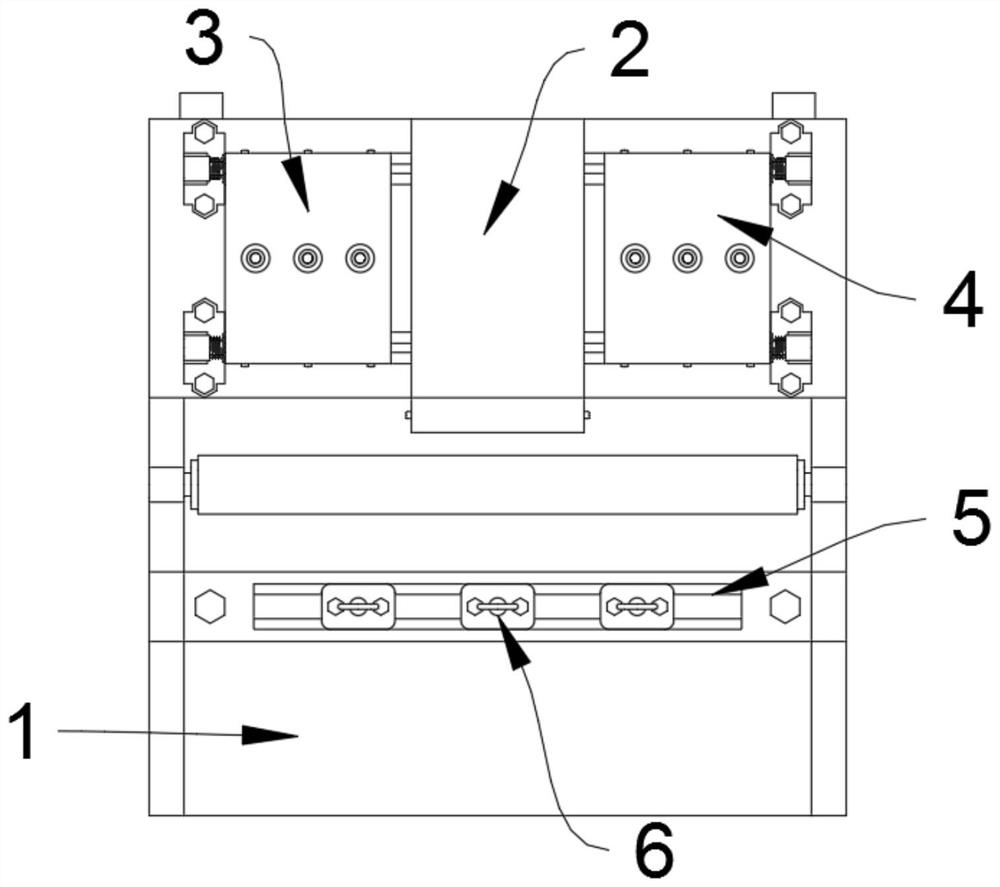

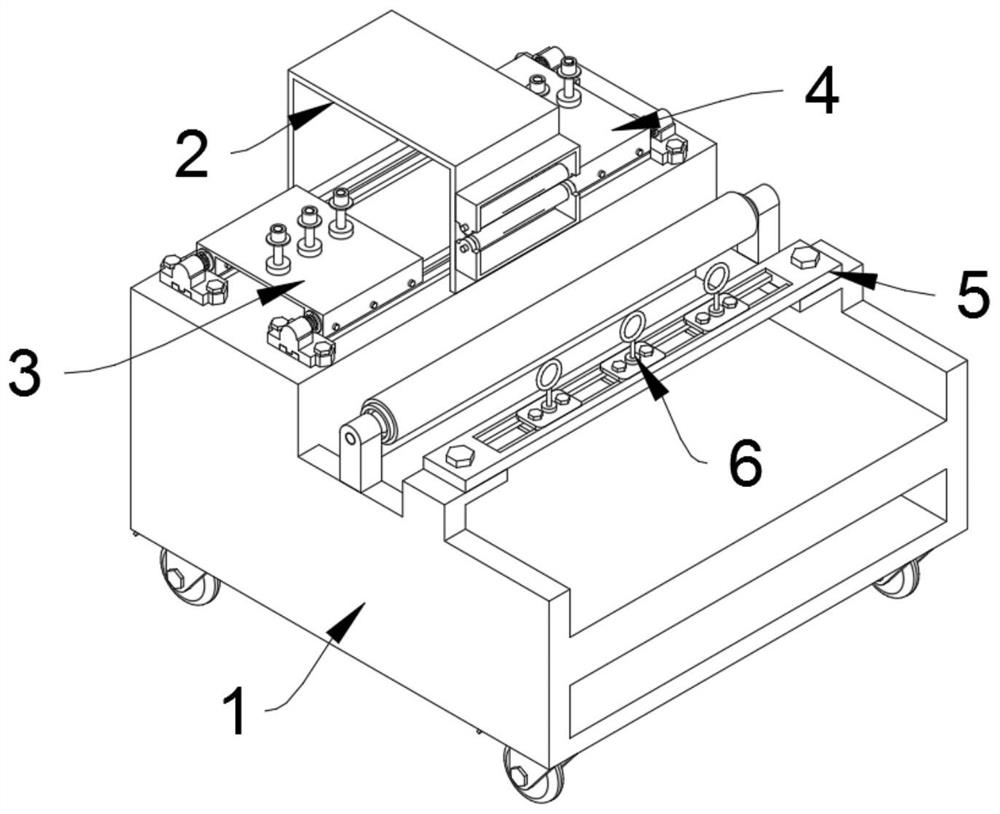

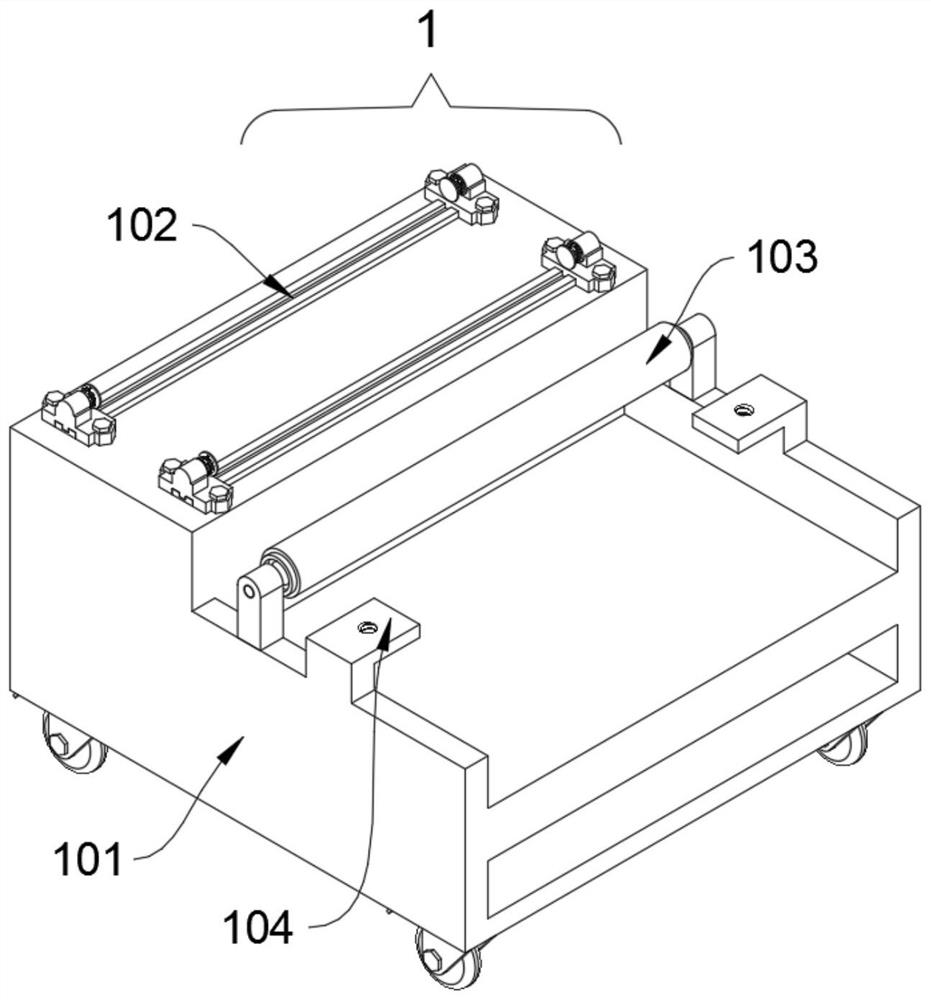

[0034] as attached figure 1 To attach Figure 11 Shown:

[0035] The present invention provides an anti-off-line spinning processing device for flax spinning devices, including: a frame mechanism 1, a first thread platform mechanism 3, a second thread platform mechanism 4, an adjustment mechanism 5, and an off-thread prevention device 6 , the middle position of the top rear end of frame body mechanism 1 is fixedly connected with the bottom of limit mechanism 2; limit mechanism 2 includes limit frame 201, first limit roller 202, second limit roller 203, behind first limit roller 202 The end is fixedly connected to the position above the front end of the limit frame 201, the rear end of the second limit roller 203 is fixedly connected to the position below the front end of the limit frame 201, the first limit roller 202 is located directly above the second limit roller 203, And the spacer 201 front end surface through groove is positioned at the position in the middle of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com