Electric power inspection robot and driving method thereof

An inspection robot and power inspection technology, applied in the field of robots, can solve the problems of insufficient human inspection and supervision, narrow cable trench environment, etc., and achieve the effect of good control, simple steps, and accurate travel trajectory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

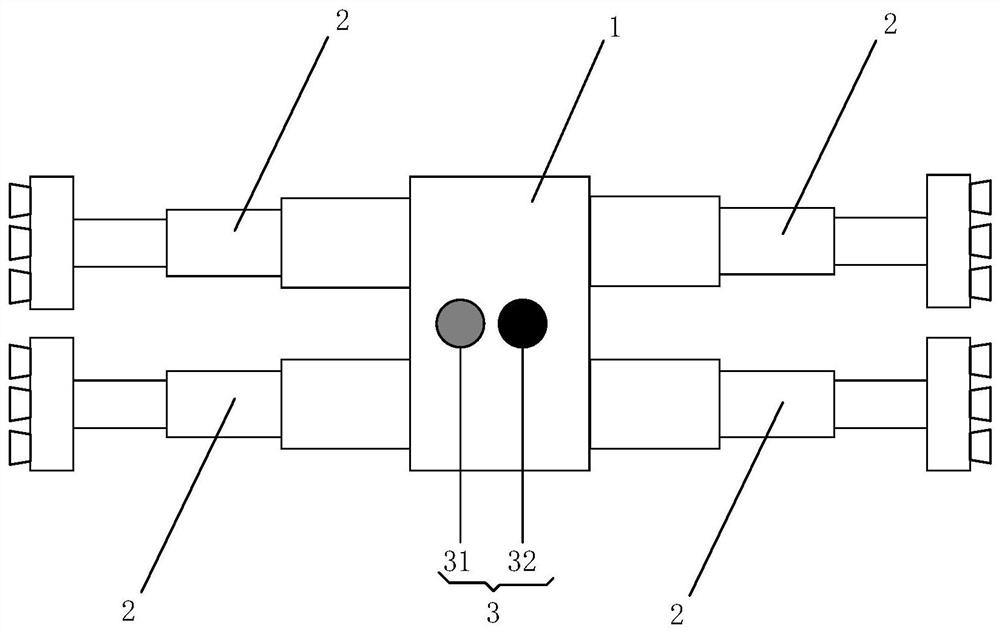

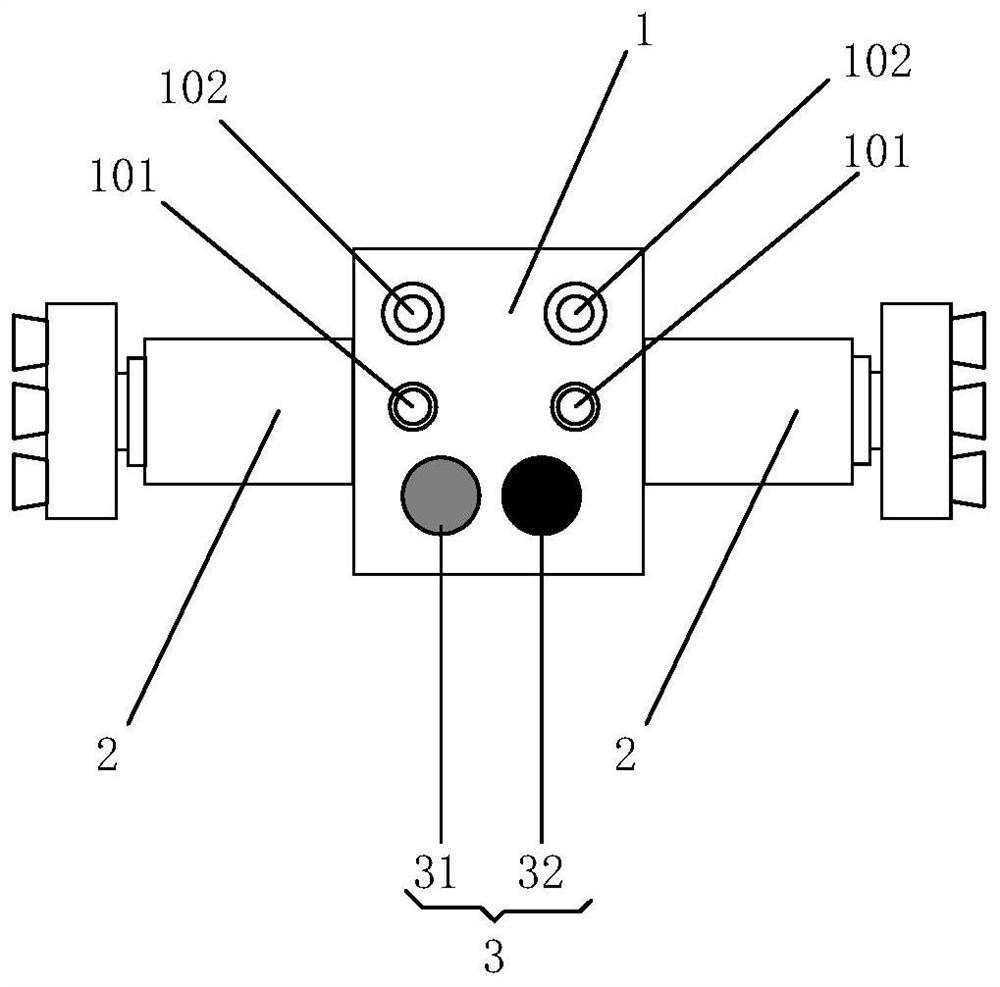

[0027] Such as figure 1 As shown, the present invention proposes a power inspection robot, including an inspection robot body 1 and two pairs of telescopic arms 2, a pair of telescopic arms 2 are coaxially arranged on the left and right sides of the front part of the inspection robot body 1, and the other pair The telescopic arms 2 are coaxially arranged on the left and right sides of the rear of the inspection robot body 1. There is an overturn drive motor for driving the inspection robot body 1 to overturn relative to one of the pair of telescopic arms 2, and the inspection robot body 1 is provided with a control module for controlling the telescopic arm 2 and the overturn drive motor.

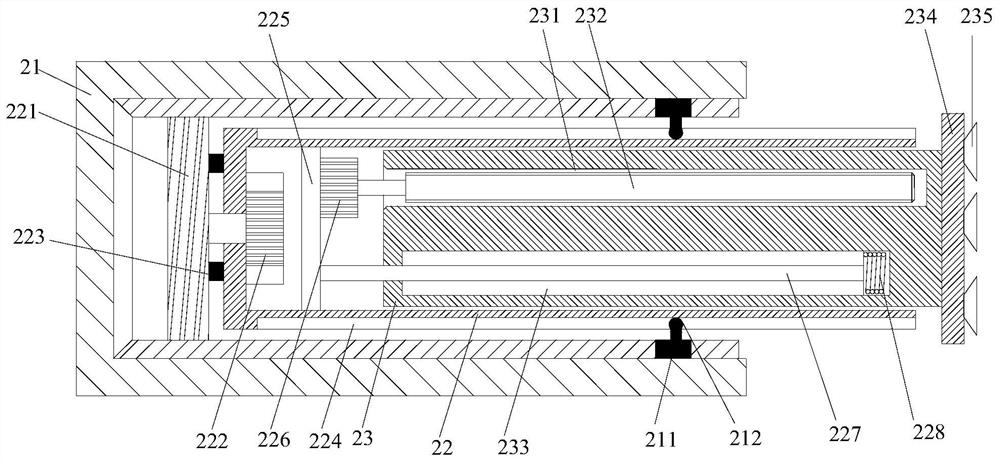

[0028] In this embodiment, the telescopic arm 2 can support the power in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com