Self-straightening machine tool cross beam

A beam and machine tool technology, applied in the field of self-aligning machine tool beams, can solve the problems affecting the overall rigidity of the machine tool frame, reducing the machining accuracy of the machine tool, and deforming the machine tool beam, so as to improve rigidity, increase manufacturing difficulty, and improve rigidity and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

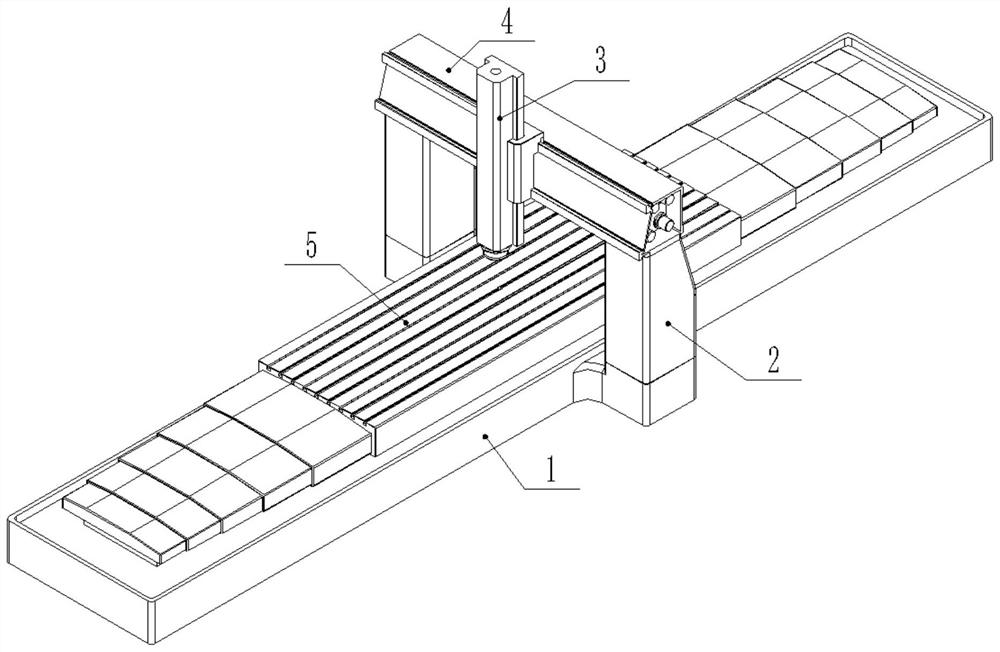

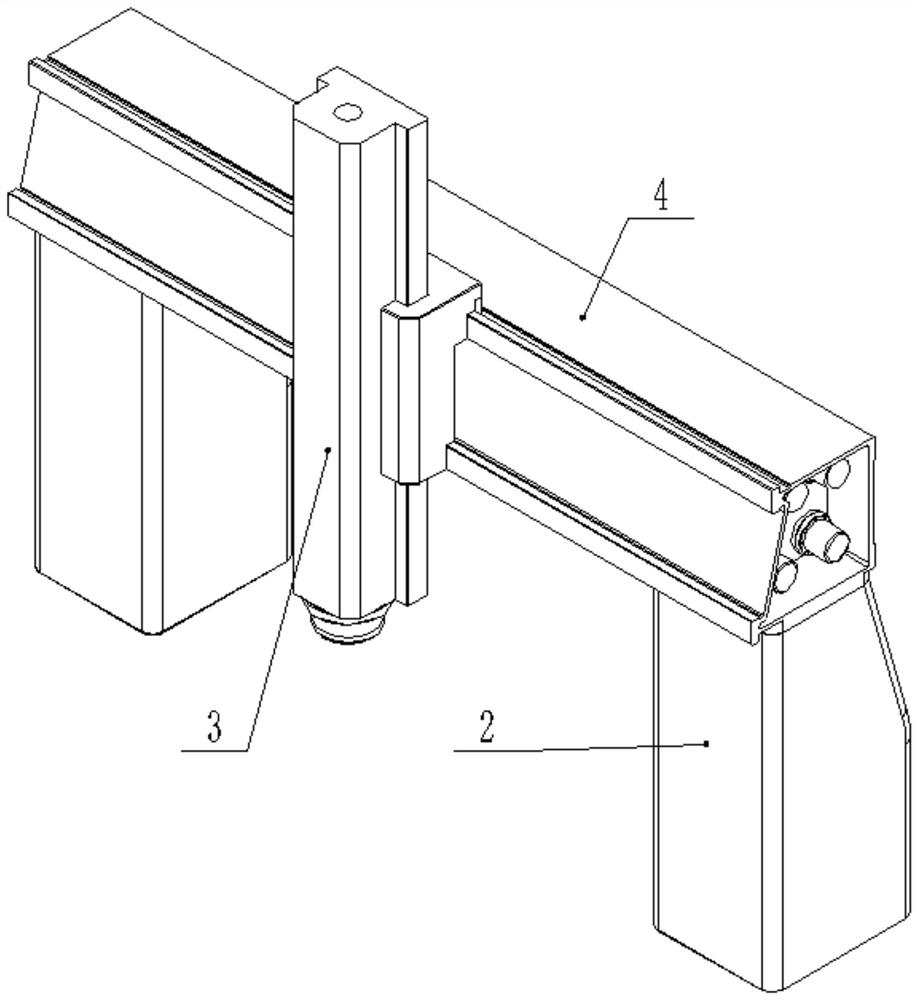

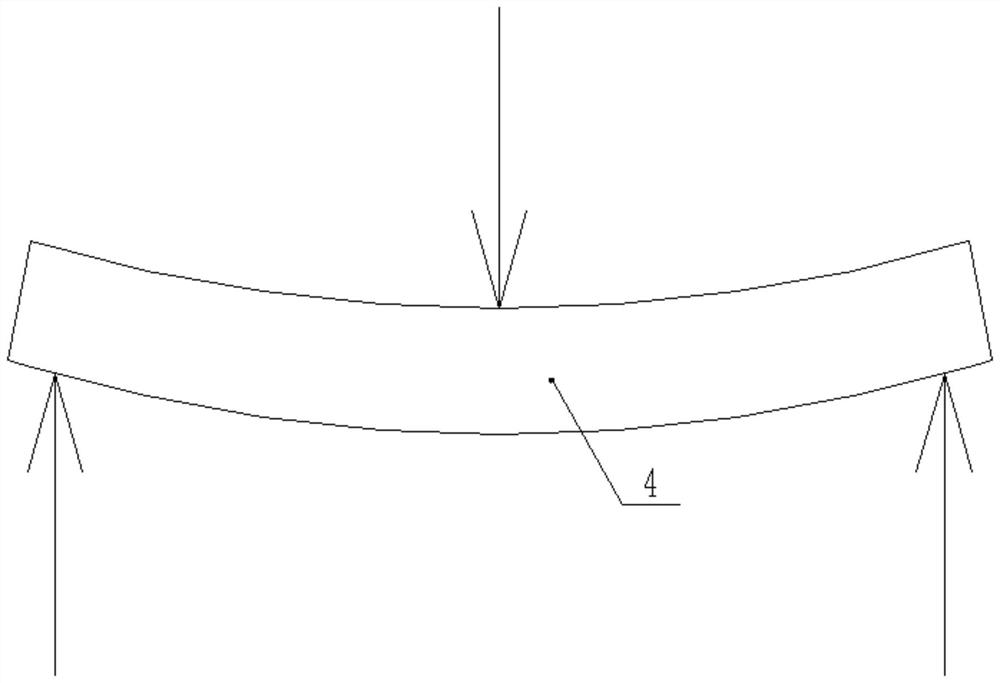

[0032] A self-straightening machine tool beam provided by an embodiment of the present invention, such as Figure 2 to Figure 11 As shown, the self-aligning machine beam provided by the embodiment of the present invention includes a beam body 401 , several tie bars 402 , a tension device, a sensor 405 , a washer 406 and a nut 407 . Such as figure 2 , Figure 7 , Figure 8 As shown, the beam body 401 and figure 2 The column 2 in the middle is connected, and the beam body 401 is a barrel-shaped structure with both ends closed, and its cross section (the cross section perpendicular to the length direction of the beam is a cross section) is rectangular or trapezoidal, and the horizontal direction of the abdominal cavity of the beam body 401 is provided with longitudinal ribs 4011, the longitudinal rib 4011 is placed in the middle of the beam body 401, and the longitudinal rib 4011 is fixedly connected to the two ends of the beam body 401. The longitudinal ribs 4011 directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com