A device for opening holes on countertops with inverted t-holes and its application

A table top, punching machine technology, applied in feeding device, positioning device, boring/drilling and other directions, can solve the problems of inverted T hole drilling, mass production construction, etc., achieve good industrial practicability, shorten operating hours, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

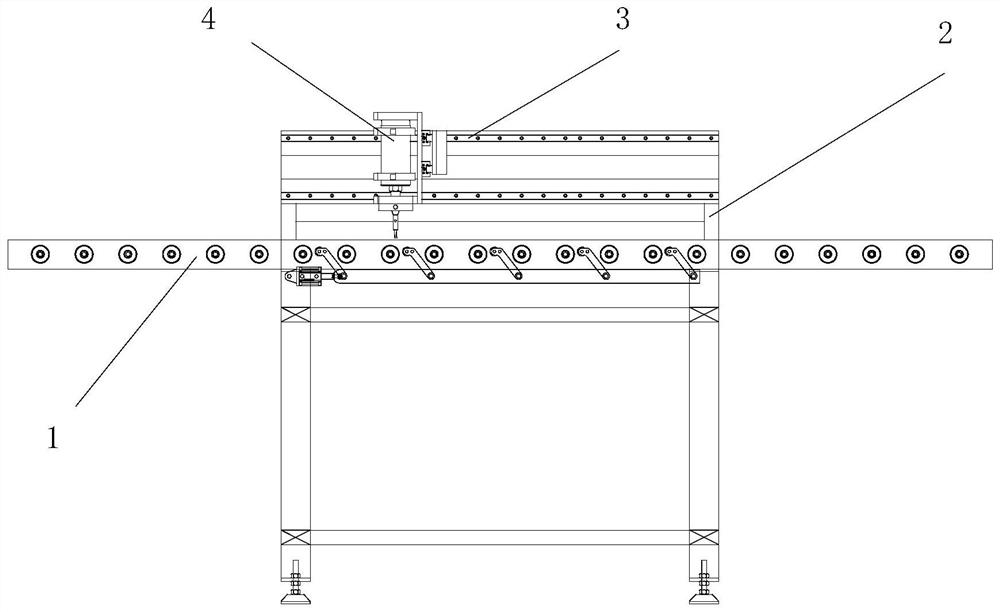

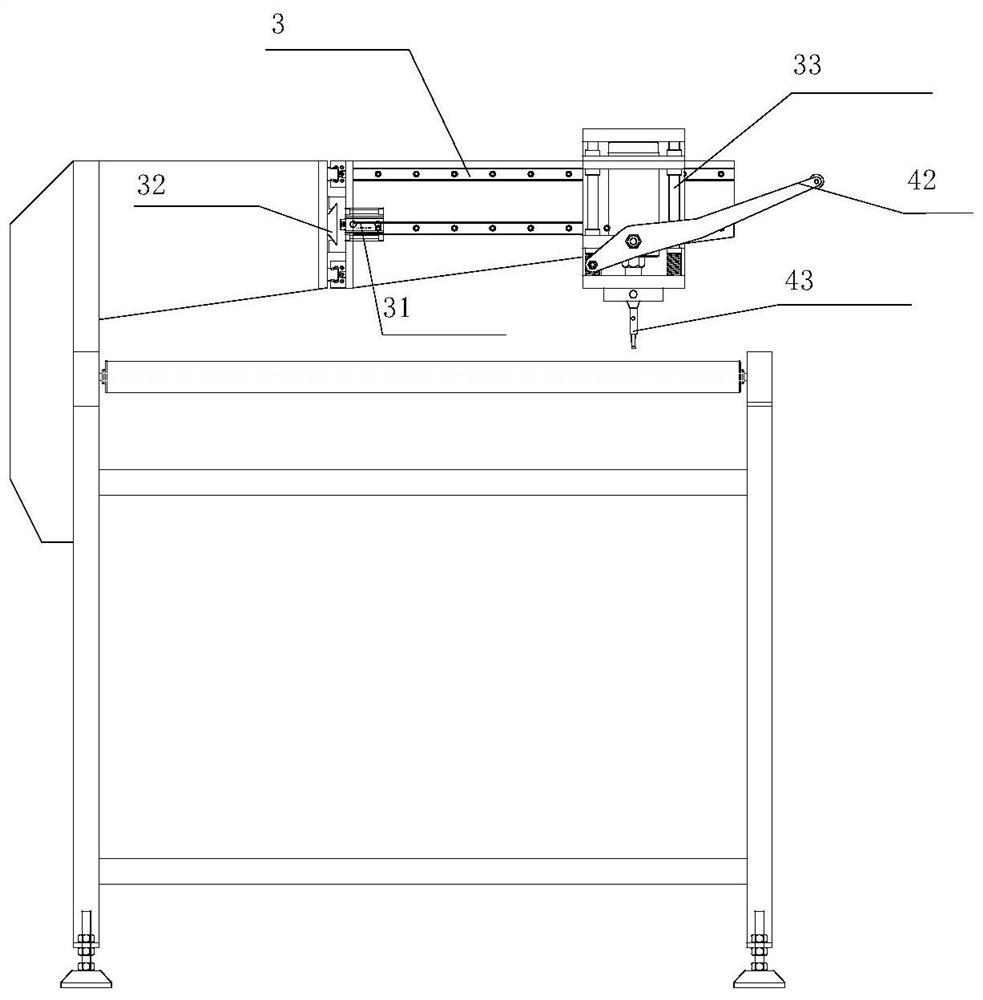

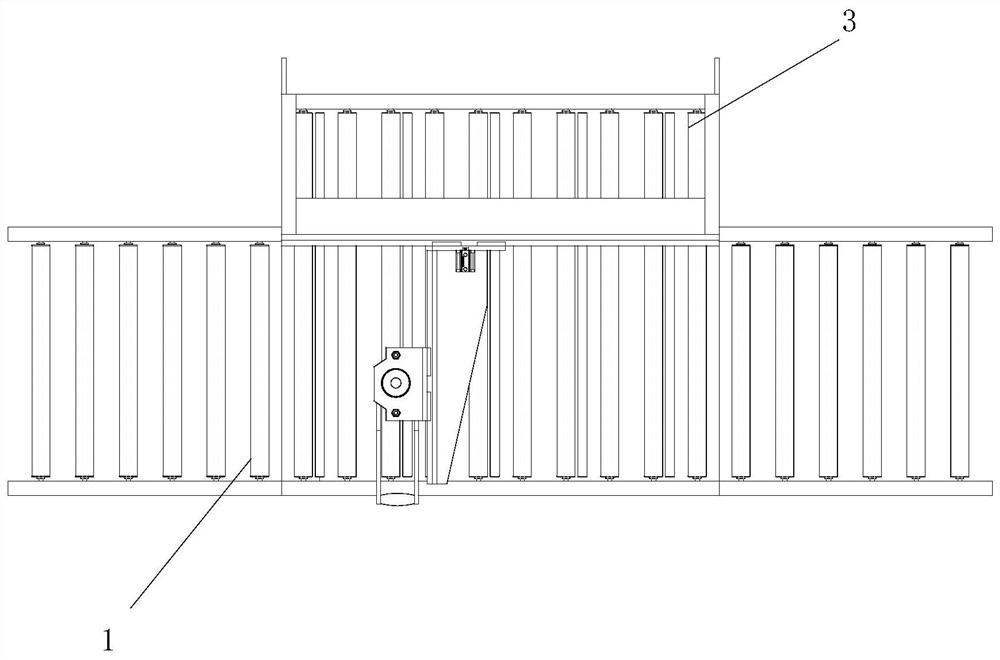

[0036] In this embodiment, a device for opening holes on an inverted T-hole table surface includes an operating table 1 and a punching machine 4, and the punching machine 4 is movably suspended above the operating table 1 through slide rails 3; A support 2, the support 2 is provided with a precision slide rail 3, including an X-axis and a Y-axis, the X-axis is parallel to the console 1, and the puncher 4 is connected to the slide rail 3 through a guide post 33 . The slide rail 3 is provided with a positioning cylinder 31, the positioning cylinder 31 is used to push the puncher 4 to move along the slide rail 3, and the tail of the positioning cylinder 31 and the slide rail 3 are connected with a dovetail chute 32.

[0037] The punching machine 4 includes an operating rod 42 , a housing 41 , a motor and a back bolt drill bit 43 .

[0038] One end of the operating rod 42 is pivotally connected to the side wall of the housing 41 , and the other end extends across the housing 41 to...

Embodiment 2

[0053] Embodiment 2 Through the blanking of the tabletop, the opening of the water tank, the turning of the turning machine to 45, trimming, and the opening of the "T" hole, etc., the production of the tabletop is quickly completed. The device in Example 1 is used to produce a countertop with an inverted T hole. The depth of the inverted T hole is 7 mm, which meets the requirement for opening large and medium islands on the countertop, and has high applicability. During the subsequent installation, you only need to fix the undermount basin to the bottom of the countertop through fasteners, gaskets and expansion screws, and quickly complete the construction of the undermount basin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com