Paint spraying device for high-altitude air fan production and manufacturing and spraying method thereof

A high-altitude air and fan technology, applied in spraying devices, devices for coating liquid on the surface, spray booths, etc., can solve problems such as standing for a long time, difficulty in spraying evenly and comprehensively, and paint splashing on the surface of the workbench. Achieve the effect of avoiding a lot of work, more automatic spraying, and saving the time required for cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

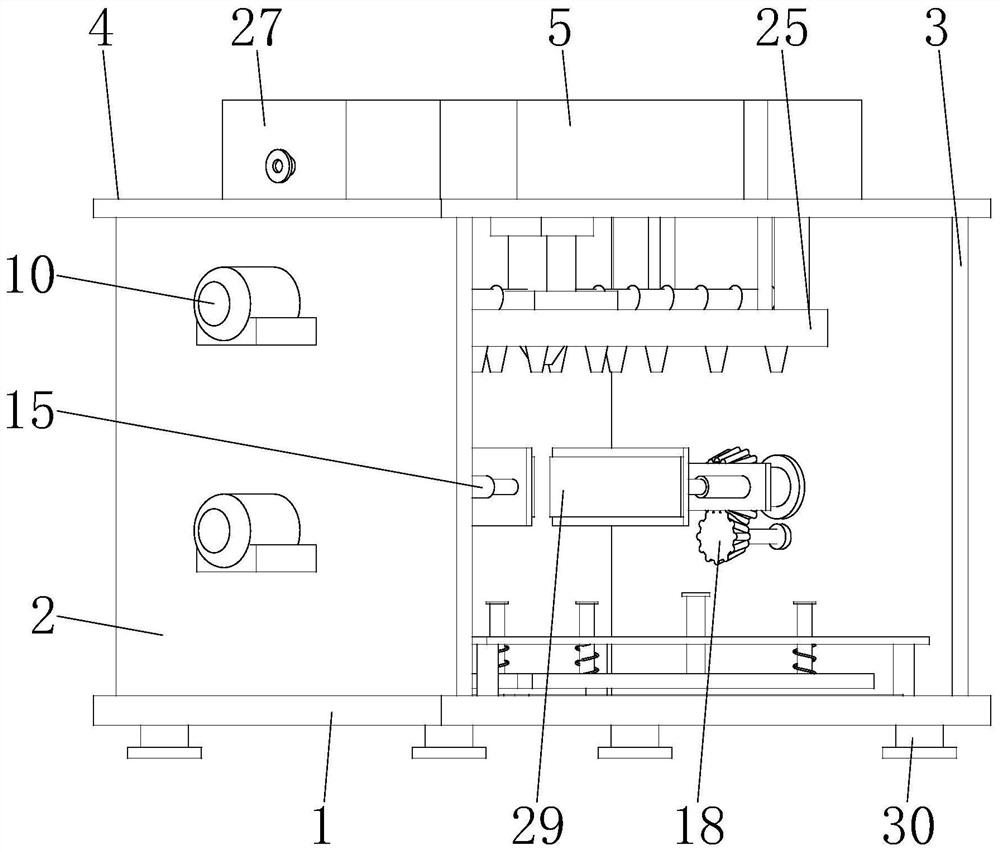

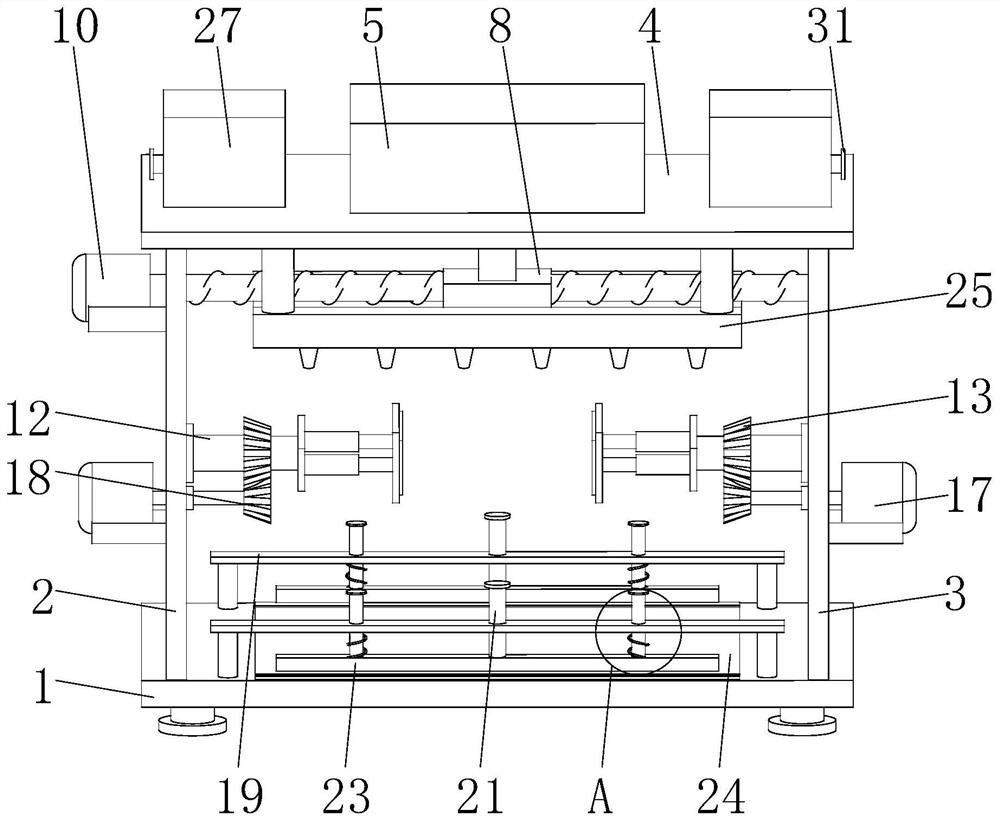

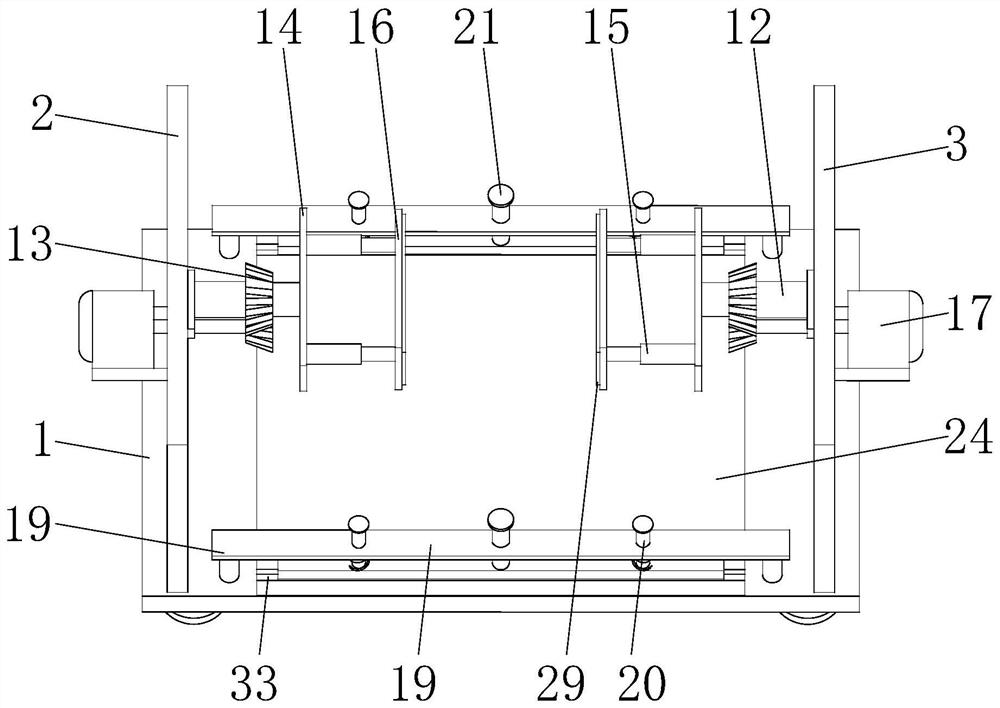

[0035] see Figure 1-6 , the present invention provides the following technical proposals: a paint spraying device for high-altitude air fan production and manufacturing, including a workbench 1, the upper end of the workbench 1 is fixedly connected with a left vertical board 2 and a right vertical board 3 respectively, and the left vertical board 2 and the right vertical board The upper end of the vertical plate 3 is fixedly connected with a top plate 4, the upper end of the top plate 4 is fixedly connected with a paint spray box 5, the lower surface of the top plate 4 is provided with a guide groove 6, and the inner wall of the guide groove 6 is slidably connected with a guide slider 7, and the guide slider 7 A threaded block 8 is fixedly connected to the lower end surface of the threaded block 8, a spraying head 9 is fixedly installed on the lower end surface of the threaded block 8, a servo motor 10 is fixedly installed on one side of the left vertical plate 2, and a thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com