Chemical paint stirring device with heating function

A technology of mixing device and chemical industry, which is applied to mixers with rotary mixing devices, accessories of mixers, transportation and packaging, etc., can solve the problems of inability to guarantee mixing of mixers, time-consuming and labor-consuming of mixers, splashing of paint, etc., and achieves a wide range of mixing. , Reasonable structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

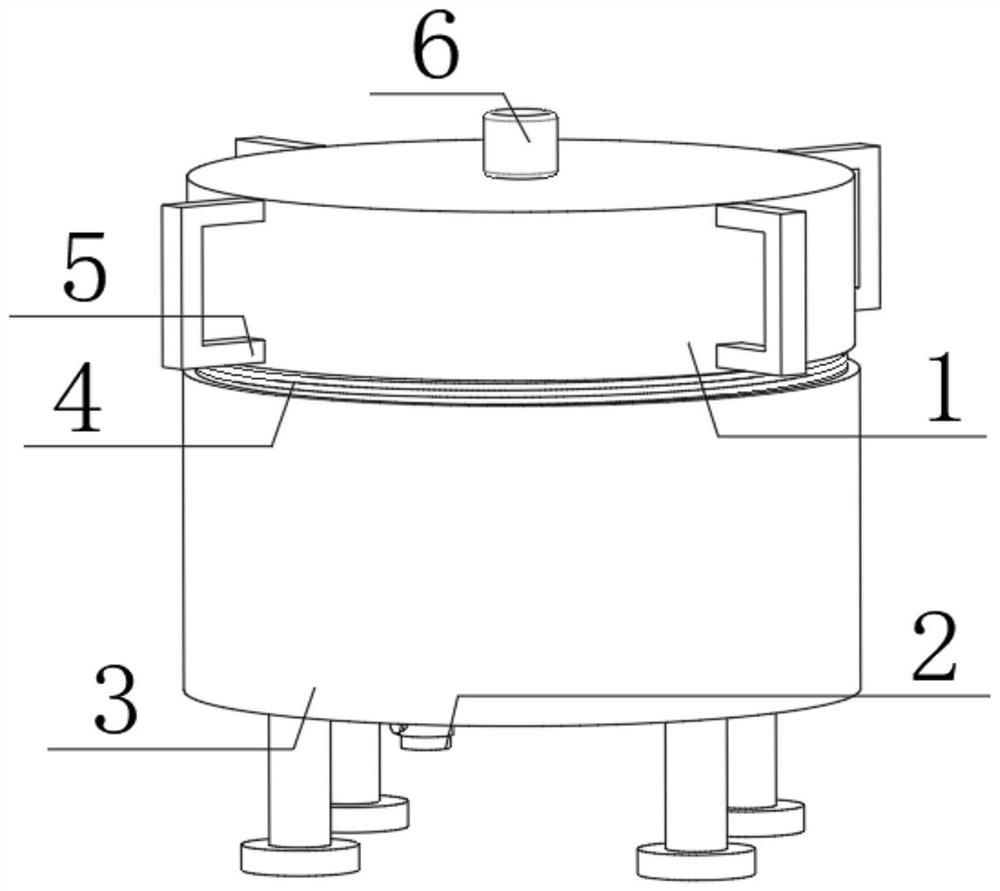

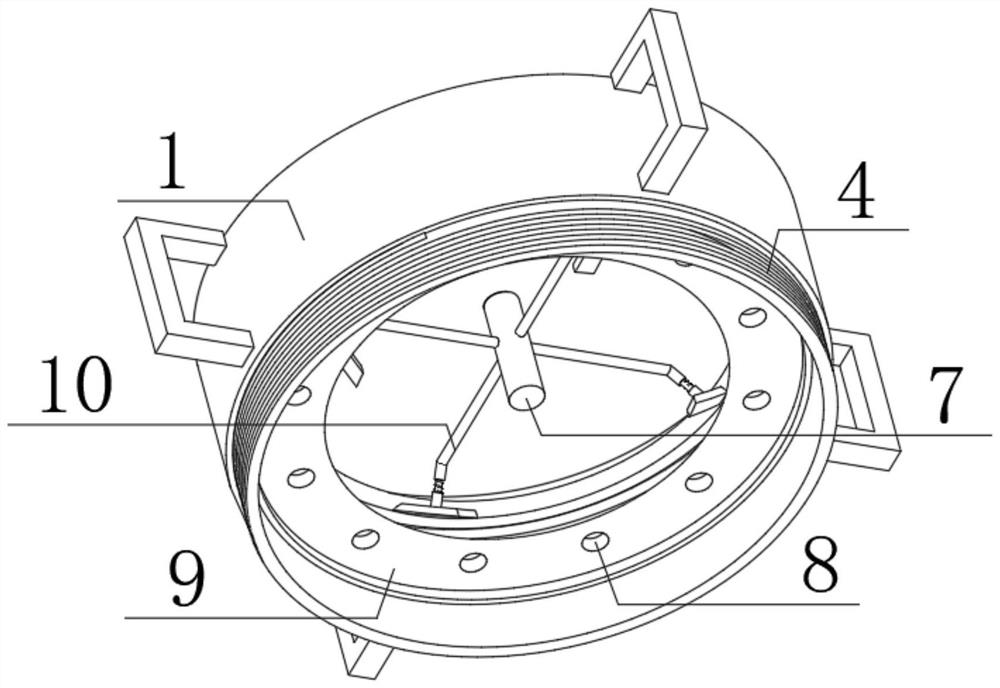

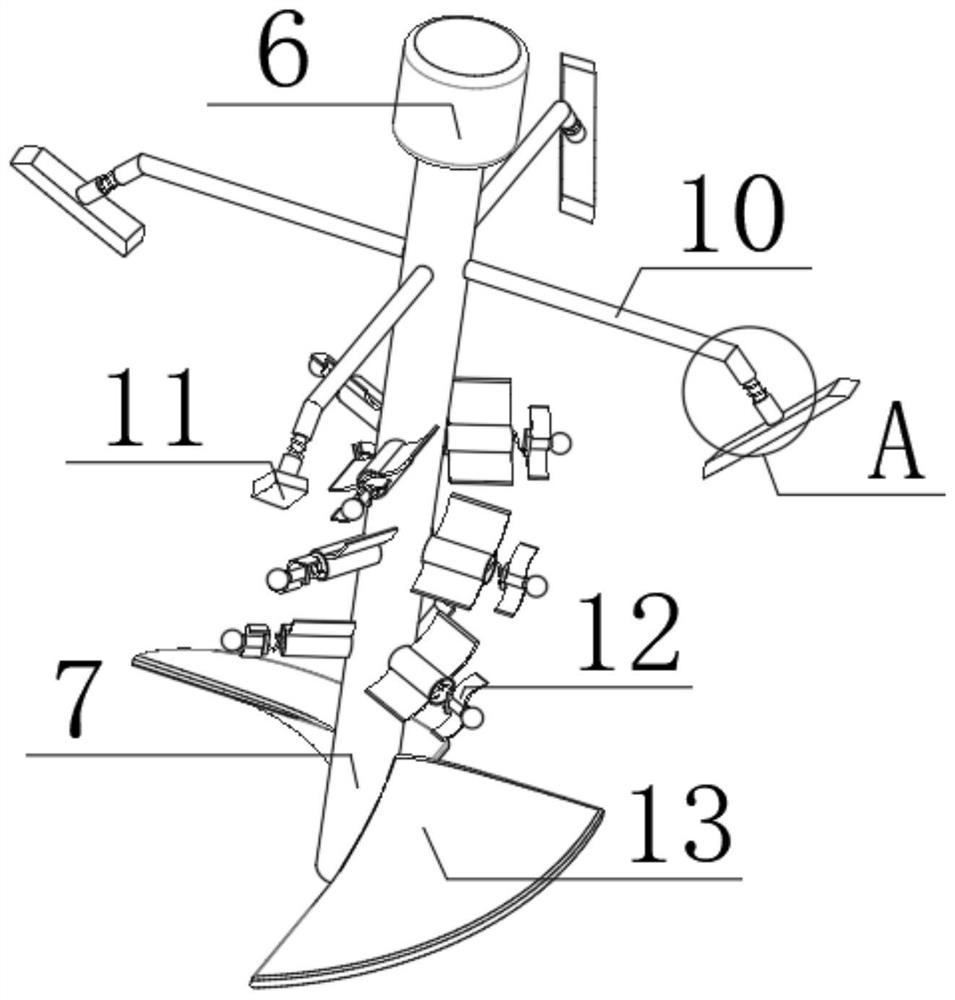

[0029] refer to Figure 1-5 , a chemical paint mixing device with a heating function, comprising a mixing tank 3, the top outer wall of the mixing tank 3 is provided with a first threaded groove 4, the inner wall of the first threaded groove 4 is threadedly connected with a box cover 1, and the box cover 1 The outer wall of the top is fixed with a motor 6 by bolts, and the output shaft of the motor 6 is connected with a rotating rod 7 through a coupling. The mounting plate is fixed by bolts, the outer wall of one side of the mounting plate is fixed with a sliding rod by bolts, one end of the sliding rod is fixed with a weight ball 15 by bolts, and the outer wall of the sliding rod is rotatably connected with a stirring plate 12, and the outer wall of the rotating rod 7 is fixed by bolts There are mixing plates 13 equidistantly distributed, the outer wall of the rotating rod 7 is provided with a liquid scraping mechanism, the inner wall of the box cover 1 is provided with a hea...

Embodiment 2

[0039] refer to Figure 6 , a chemical paint stirring device with a heating function. Compared with Embodiment 1, this embodiment also includes a thermal insulation foam 21 arranged on the inner wall of the heat storage tank.

[0040] When in use, the thermal insulation foam 21 can store the heat in the heat storage tank, thereby maintaining the heat in the heat storage tank for a long time, and then continuously heating the paint in the inner tube 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com