Preposed pressure-stabilizing backwashing filter

A pre-stabilizing and filter technology, applied in fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of water leakage, rupture, filter burst and collapse at the connecting pipe, and prevent water leakage. and burst effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

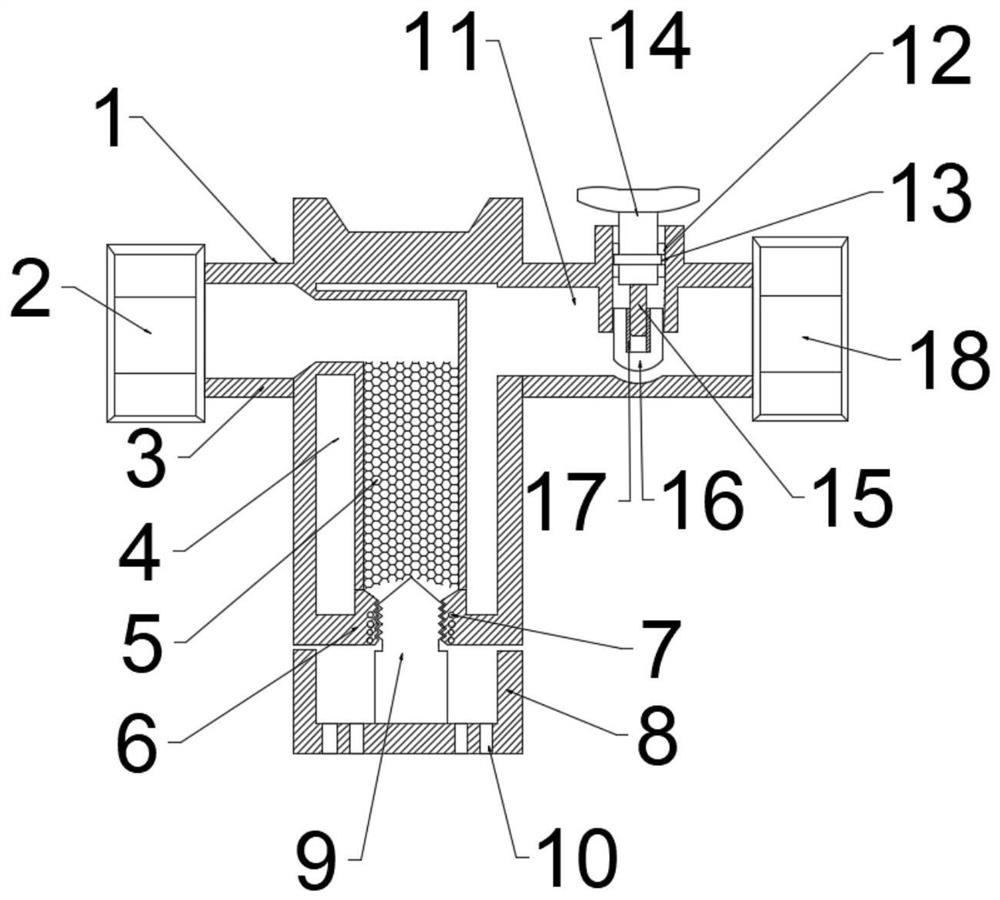

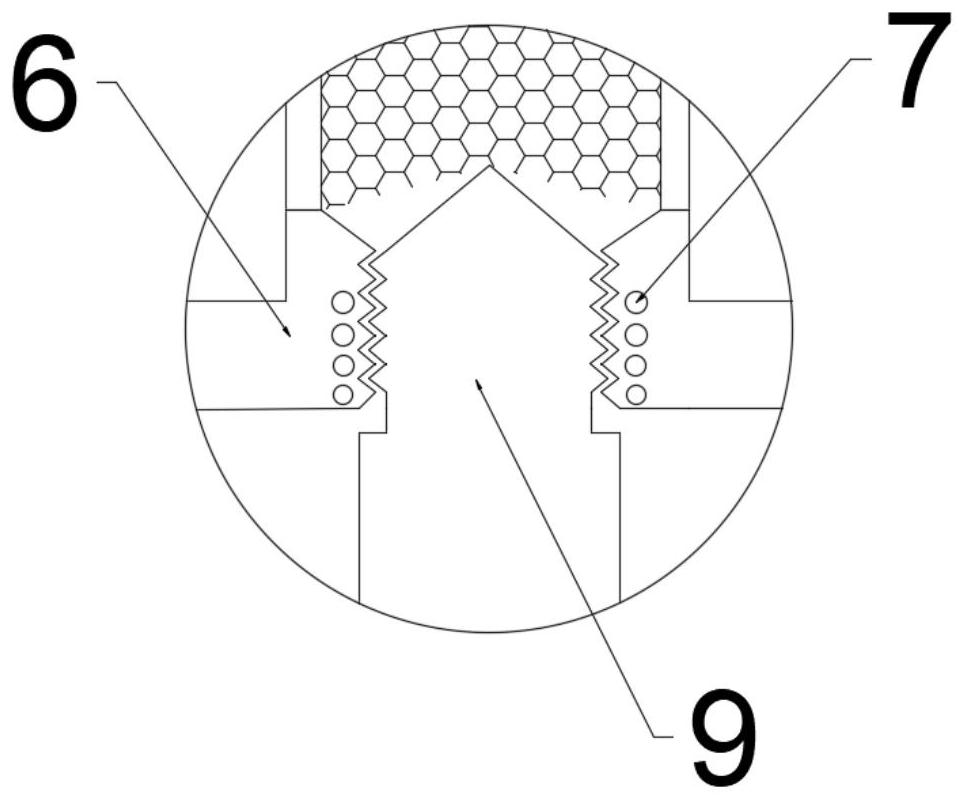

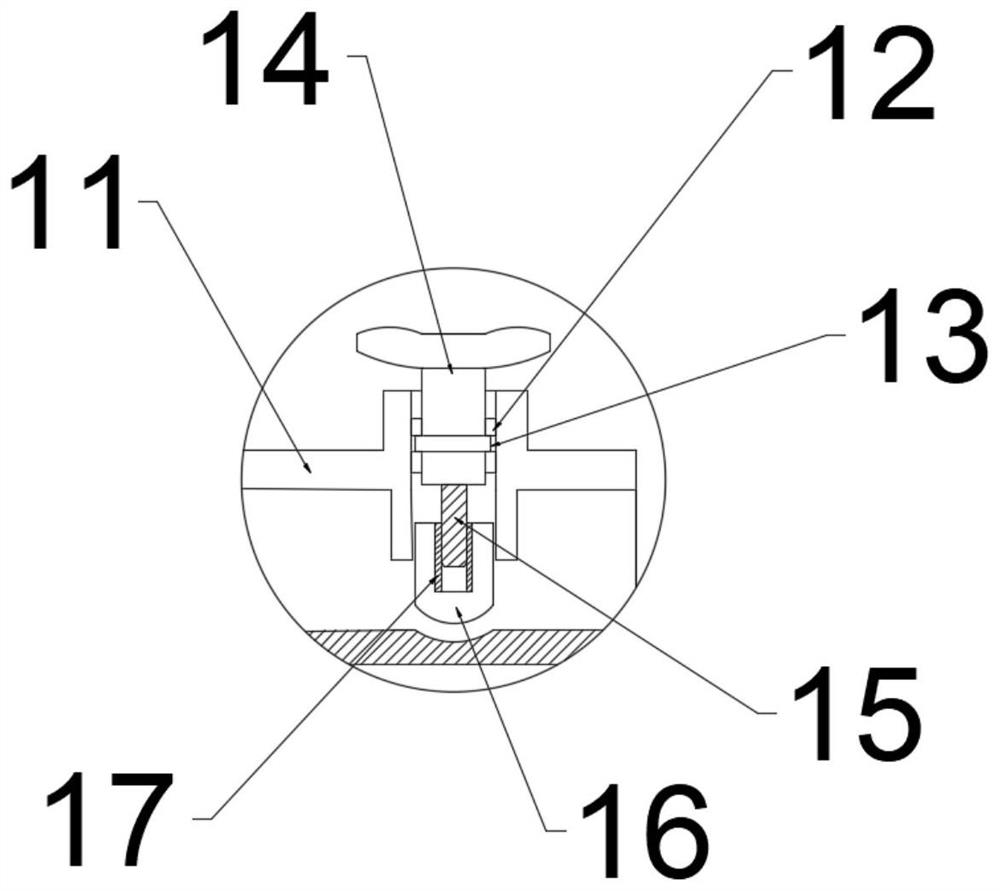

[0025] see Figure 1 ~ Figure 3 , a pre-stabilized recoil filter, including a filter chamber 4, a filter membrane 5, a threaded port 6, a pressure relief hole 7, a sealing column 9 and a shut-off valve 16, wherein the filter membrane 5 for water purification is installed in the shell In the middle of the body 1, a filtration chamber 4 is provided outside the filter membrane 5, a threaded port 6 is provided below the filter film 5, a pressure relief hole 7 is provided on the thread of the threaded port 6, and a filter for sealing the filter film is provided below the threaded port 6. 5 of the sealing column 9, the right side of the housing 1 is provided with a shut-off valve 16 for pressure stabilization.

[0026] The left side of the housing 1 is provided with a water inlet port 2, and the right side of the water inlet port 2 is installed with a water inlet pipe 3. The water inlet port 2 is connected to the housing 1 through the water inlet pipe 3, and the right side of the wa...

Embodiment 2

[0030] see Figure 4 , a pre-stabilized recoil filter, the main structure of which is the same as that of Embodiment 1, and the filter membrane 5 is improved, and a card slot 19 is installed at the end of the water inlet pipe 3, and the filter membrane 5 is installed in the filter membrane shell 20 Above, a threaded end 21 is provided between the filter membrane case 20 and the housing 1 , and the filter membrane case 20 is fixed on the housing 1 through the threaded end 21 .

[0031] The working principle of the present invention is: when the filter membrane 5 needs to be replaced, first remove the base 8 from below, then unscrew the filter membrane shell 20 from the inside of the housing 1, replace the filter membrane 5, and then Insert the filter membrane case 20 into the casing, make the top of the filter membrane case 20 snap into the slot 19, then tighten the threaded end 21, and then tighten the base 8 upwards to complete the replacement of the filter membrane 5.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com