Garlic processing assembly line control system, assembly line and method

A technology of control system and assembly line, applied in general control system, control/regulation system, comprehensive factory control, etc., can solve the problems of automatic control of assembly line equipment, inability to integrate, unified control, etc., and achieve integrated control and automatic control , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

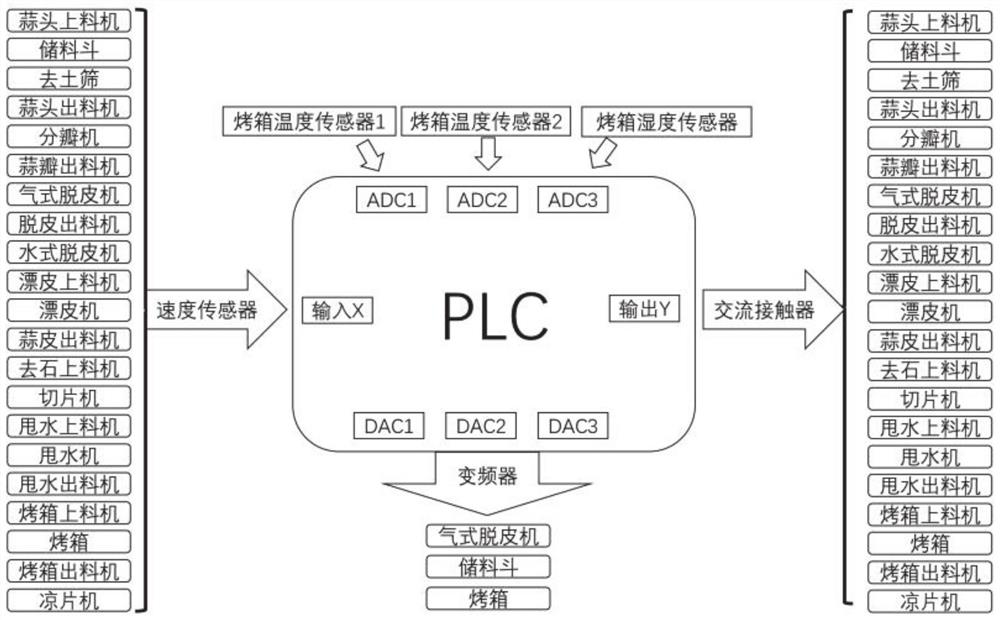

[0036] An embodiment of the present invention provides a garlic processing assembly line control system, including a power distribution cabinet, the power distribution cabinet is provided with a main power switch, a PLC touch screen integrated machine, a relay, an AC contactor, a relay, an AC contactor Depending on the specific connected devices, each device corresponds to a relay and an AC contactor.

[0037] The AC contactor is used to access the power line of the equipment, and the AC contactor is connected to the main power switch in the power distribution cabinet; the AC contactor is connected to the corresponding interface of the PLC touch screen integrated machine through a relay. The corresponding program is set through the PLC, and the integrated automatic control of the garlic processing line equipment is realized through the switch on the PLC touch screen all-in-one machine.

[0038] Further, such as figure 2 As shown, the input end of the PLC touch screen all-in-...

Embodiment 2

[0042] This embodiment also provides a garlic processing line, which includes implementing the above-mentioned control system, and also includes a plurality of devices, and the devices are connected to the control system.

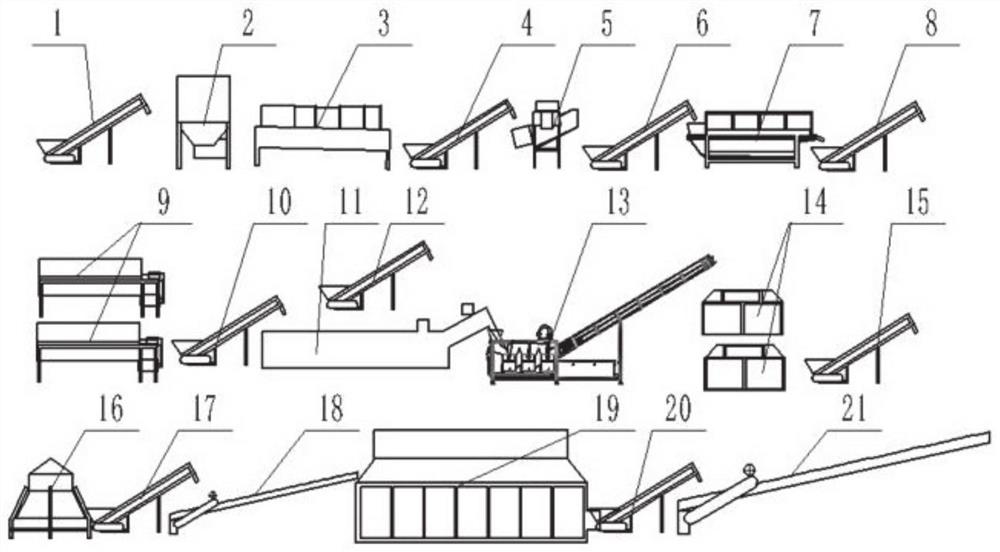

[0043] In this embodiment, according to the garlic processing process: soil removal-separation-peeling-stone removal-slicing-spinning-drying, etc., the arrangement of garlic processing equipment is formulated, which can effectively improve the processing efficiency. Such as figure 1 As shown, the equipment is a garlic feeder 1, a storage hopper 2, a soil removal sieve 3, a garlic discharge machine 4, a splitter 5, a discharge machine 6, a gas peeling machine 7, and a peeling discharge machine arranged in sequence. Machine 8, water peeling machine 9, peeling machine 10, peeling machine 11, garlic peeling machine 12, stone removing machine 13, slicing machine 14, water throwing machine 15, water throwing machine 16, throwing Water discharging machine 17, ove...

Embodiment 3

[0047] This embodiment also provides a control method of a garlic processing line, adopting the production line described in Embodiment 2, its control process is as follows Figure 4 and Figure 5 shown, including:

[0048] Pre-set the start and stop sequence of each device, press the start button of the PLC touch screen all-in-one machine, and each device will start according to the set time; if the stop button is pressed, each device will stop running. And the manual can start and stop each equipment at any time to facilitate maintenance.

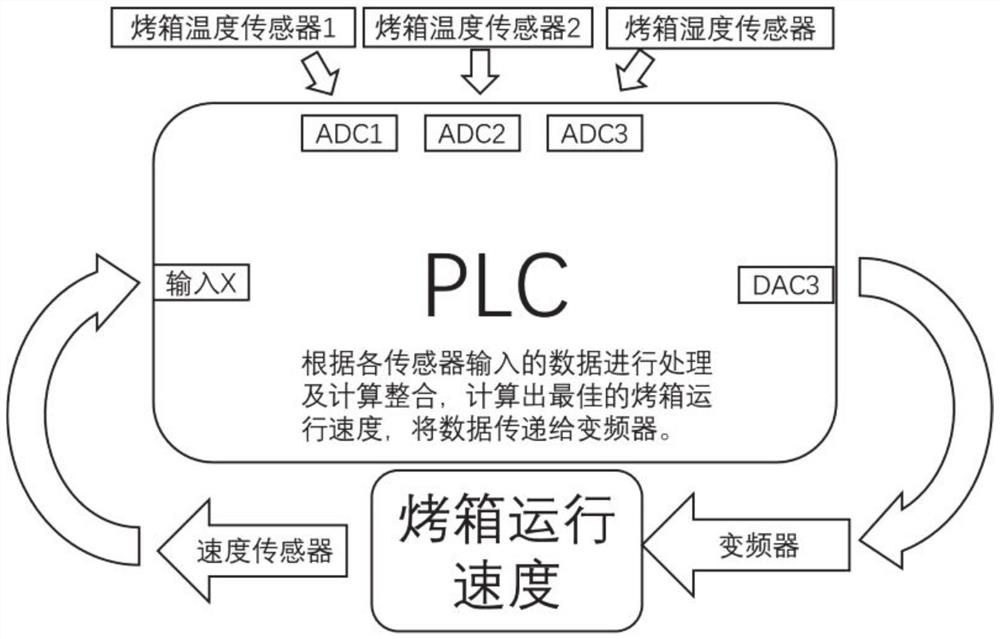

[0049] Real-time monitoring of equipment operation status through the PLC touch screen integrated machine: for example, real-time monitoring of the humidity and temperature of the oven 19, and real-time monitoring of the operating speed of each equipment.

[0050] Record the temperature, humidity and operating speed of the oven 19 at the corresponding time, and calculate a reasonable operating speed to improve the baking quality.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com