Broken rock coring device for geotechnical engineering investigation

A technology for crushing rocks and coring devices, applied in the direction of sampling devices, etc., can solve problems such as failure to achieve good coring results, failure of coring in hard soil layers, low coring efficiency and quality, and improve coring Efficiency and quality, good overall structural stability, and the effect of reducing vibration of drilling tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

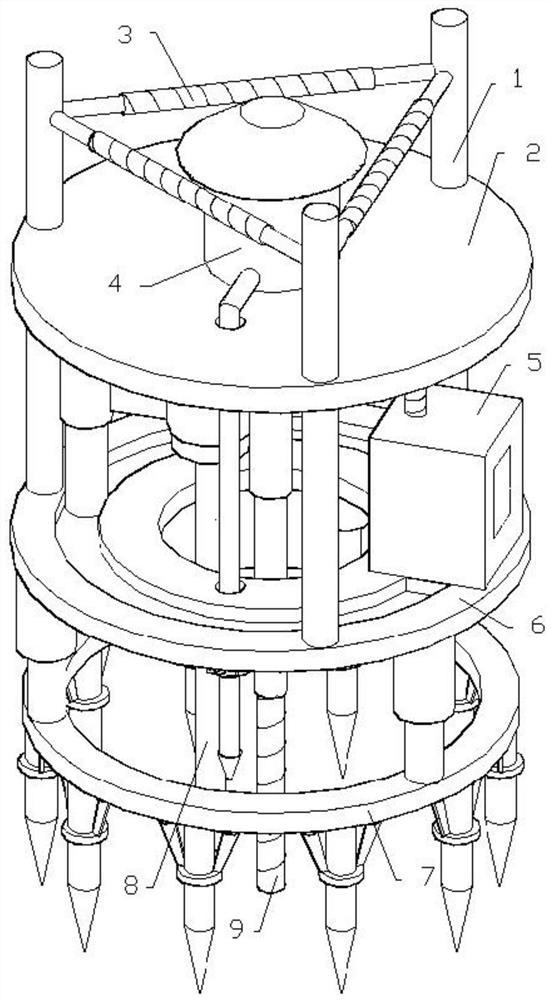

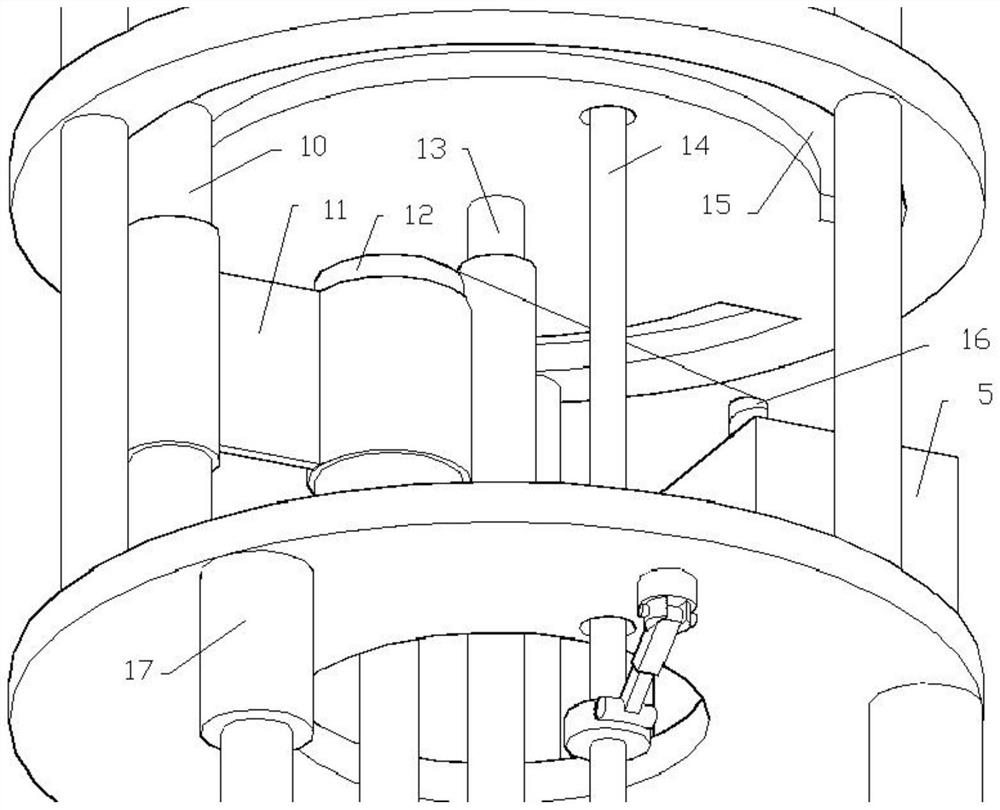

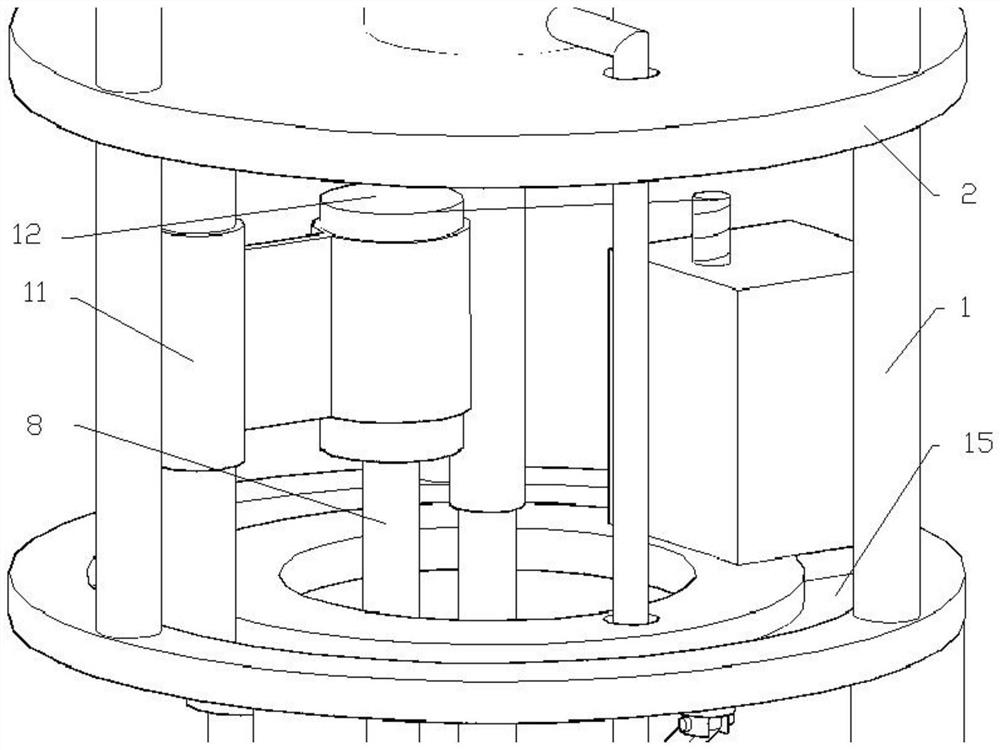

[0020] Such as Figure 1 to Figure 4 As shown, a geotechnical engineering survey broken rock coring device includes a disc-shaped top plate 2, a hollow disc-shaped bottom plate 6 and a circular pressure plate 7 arranged up and down on the same normal line, between the top plate 2 and the bottom plate 6 It is connected and fixed by three connecting columns 1 distributed in an equilateral triangle at the corresponding positions around the edges, and the bottom plate 6 and the pressure plate 7 are connected by three hydraulic piston cylinders 17 distributed in an equilateral triangle at the corresponding positions around the edges. There is a glue liquid tank 4 and the outlet of the glue liquid tank 4 is externally connected with an infusion pipeline 14, and the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com