A kind of detection equipment and detection method of automobile wheel after forming

A technology of automobile wheel hub and testing equipment, which is applied in the direction of measuring device, mechanical diameter measurement, mechanical measuring device, etc., can solve the problems of decreased work efficiency, prolonged testing process time, low degree of stability of wheel hub, etc., to improve the degree of clamping, improve the Relative stillness, the effect of achieving reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 13 , to further elaborate the present invention.

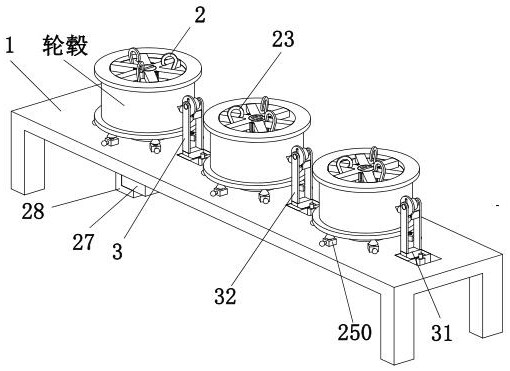

[0040] A detection device after forming an automobile wheel hub, comprising a workbench 1, a clamping mechanism 2 and a detection mechanism 3, the upper end of the workbench 1 is provided with a clamping mechanism 2, and the right side of the upper end of the clamping mechanism 2 is provided with a detection mechanism 3.

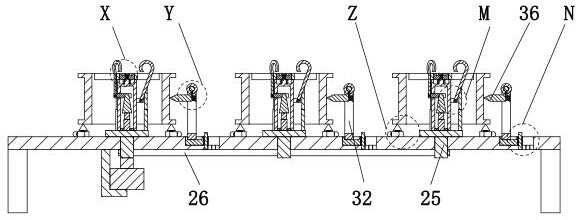

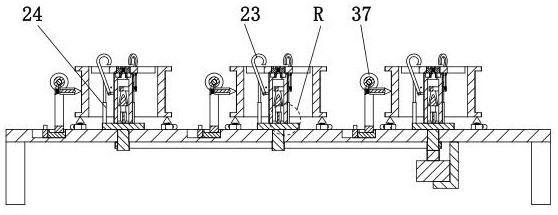

[0041] The clamping mechanism 2 includes a disc 20, a stepped column 21, a pair of ear plates 22, a clamping claw 23, a No. 1 electric push rod 24, a connecting shaft 25, a belt 26, a motor 27 and a base 28, and the disc 20 Installed on the upper end surface of the workbench 1 equidistantly from left to right by sliding fit, the middle part of the upper end surface of the disc 20 is equipped with a stepped column 21, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com