A drying control method of a clothes dryer and a clothes dryer

A technology of drying control and clothes dryer, applied in the field of clothes dryer, which can solve problems such as uneven drying of clothes, few humidity sensors, over-drying of clothes, etc., and achieve reasonable and intelligent setting of drying time and energy consumption Improved utilization rate and precise drying control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

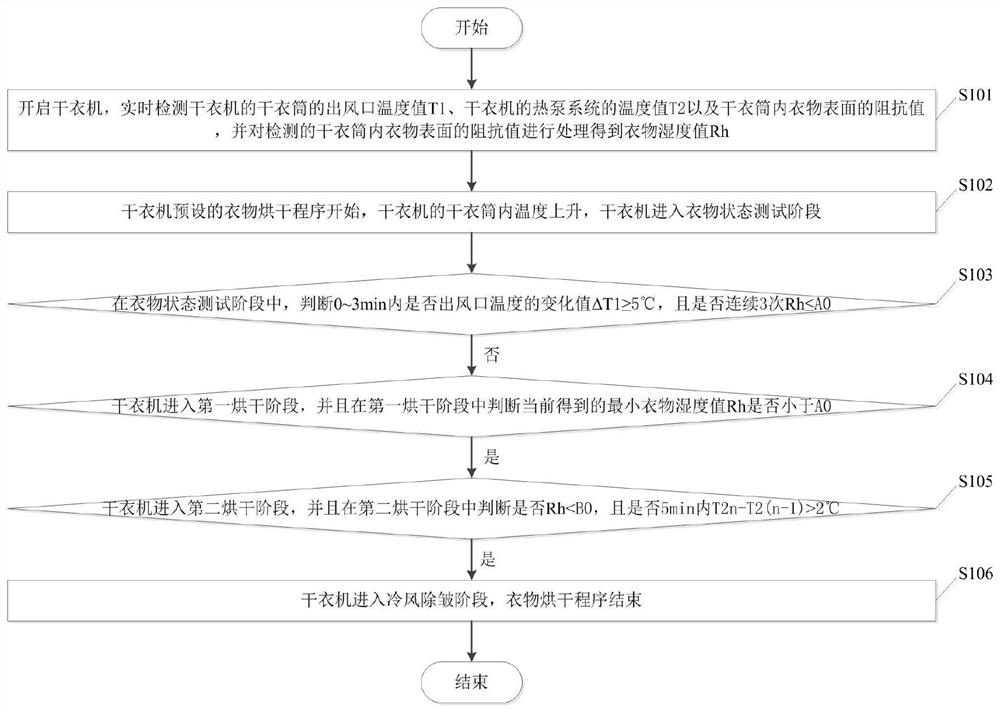

[0034] Embodiment 1 of the present invention provides a drying control method for a clothes dryer, figure 1 It is a flow chart of a drying control method of a clothes dryer according to the first embodiment of the present invention, as figure 1 shown, including the following steps:

[0035] Step S101: Turn on the clothes dryer, detect in real time the temperature value T1 of the air outlet of the clothes dryer of the clothes dryer, the temperature value T2 of the heat pump system of the clothes dryer, and the impedance value of the clothes surface in the clothes dryer, and make an analysis of the detected clothes dryer. The impedance value of the clothes surface in the clothes tub is processed to obtain the clothes humidity value Rh;

[0036] In the embodiment of the present invention, after the clothes dryer is turned on, the drive motor and the heat pump system of the clothes dryer start to work, the clothes drying program used in the clothes dryer also starts, and hot air ...

Embodiment 2

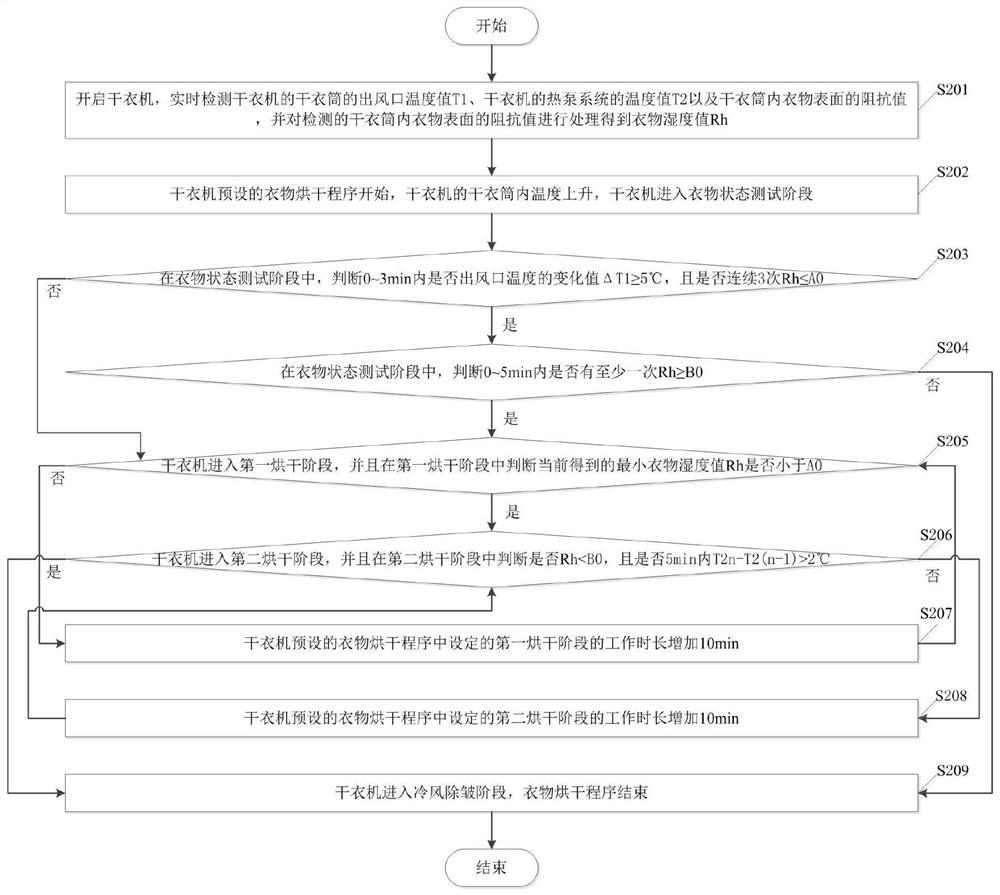

[0054] This embodiment provides another drying control method for a clothes dryer, such as figure 2 shown, figure 2 It is a flowchart of another drying control method for a clothes dryer according to the second embodiment of the present invention, including the following steps:

[0055] Step S201: Turn on the clothes dryer, detect in real time the temperature value T1 of the air outlet of the clothes dryer of the clothes dryer, the temperature value T2 of the heat pump system of the clothes dryer, and the impedance value of the clothes surface in the clothes dryer, and measure the detected drying value. The impedance value of the clothes surface in the clothes tub is processed to obtain the clothes humidity value Rh;

[0056] In the embodiment of the present invention, after the clothes dryer is turned on, the drive motor and the heat pump system of the clothes dryer start to work, the clothes drying program used in the clothes dryer also starts, and hot air starts to blow ...

Embodiment 3

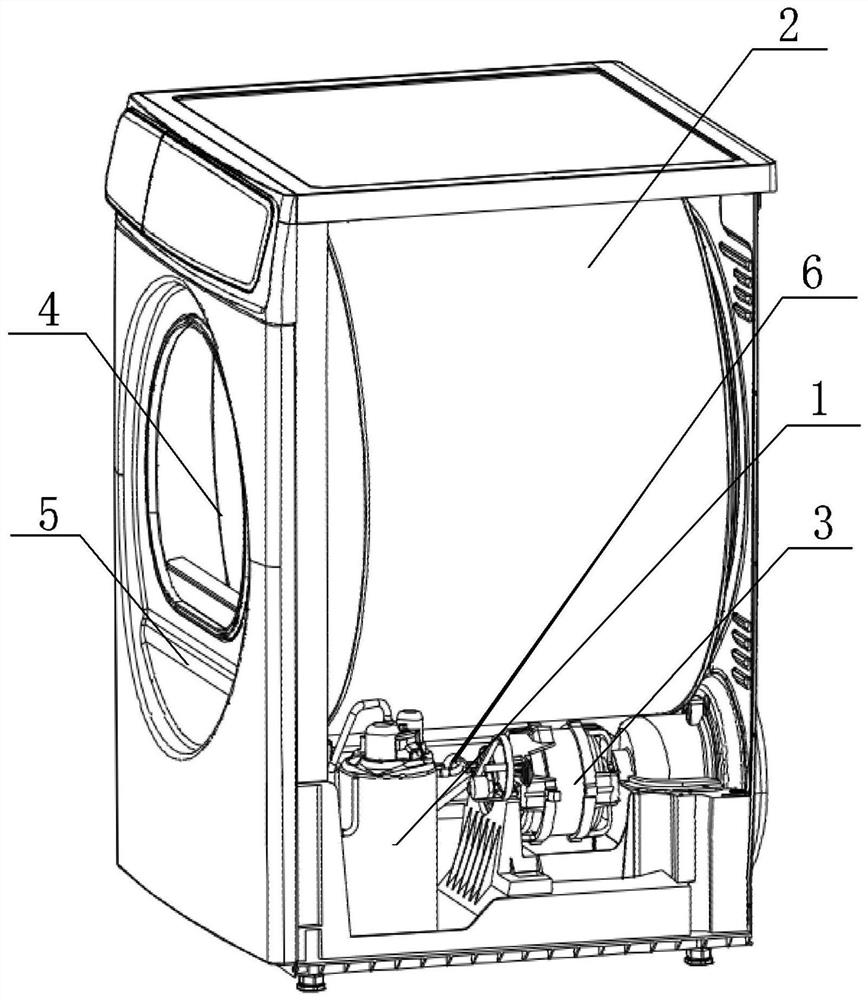

[0081] This embodiment provides a clothes dryer whose structure is as follows image 3 shown, image 3 It is a structural diagram of a clothes dryer according to the third embodiment of the present invention, including a heat pump system 1, a drying cylinder 2, a driving motor 3, a control circuit board, a metal sheet 4 arranged on the inner wall of the drying cylinder 2, and a metal sheet 4 arranged on the drying cylinder 2. The first temperature sensor 5 at the air outlet and the second temperature sensor 6 provided on the heat pump system 1, the heat pump system 1, the driving motor 3, the metal sheet 4, the first temperature sensor 5 and the second temperature sensor 6 are all connected with the control circuit. The board is electrically connected, and the preset clothes drying program algorithm is stored in the control circuit board, and the clothes dryer is controlled by the aforementioned drying control method.

[0082] Optionally, the metal sheet 4 is used to detect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com