Adhesive tape and preparation method of display panel

A display panel and tape technology, which is applied in the manufacturing of adhesives, films/sheets without carriers, semiconductor/solid-state devices, etc., can solve problems such as wrinkles, and achieve the effect of preventing wrinkles and facilitating adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

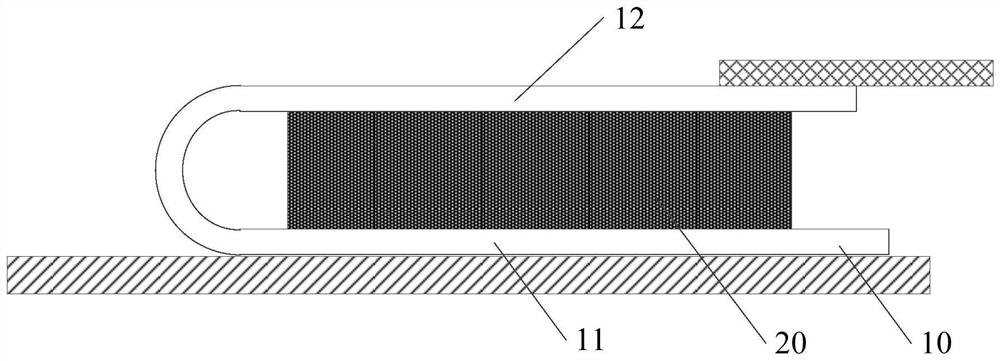

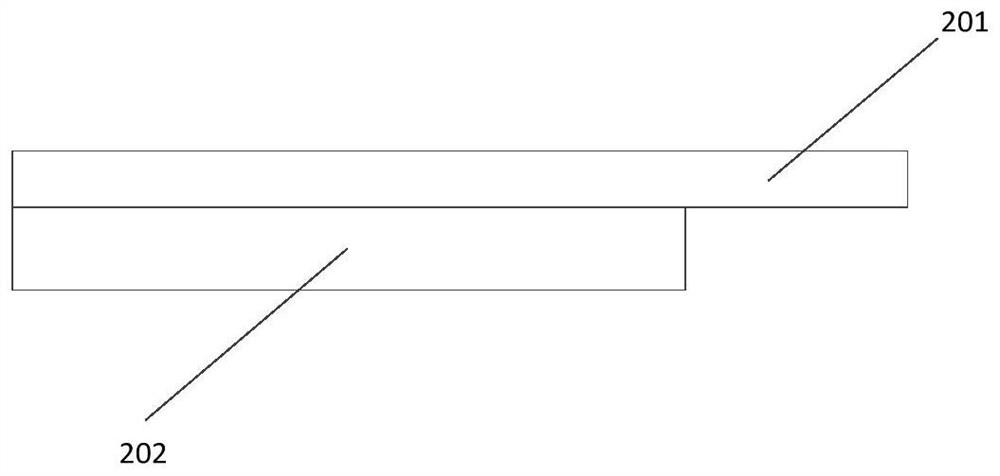

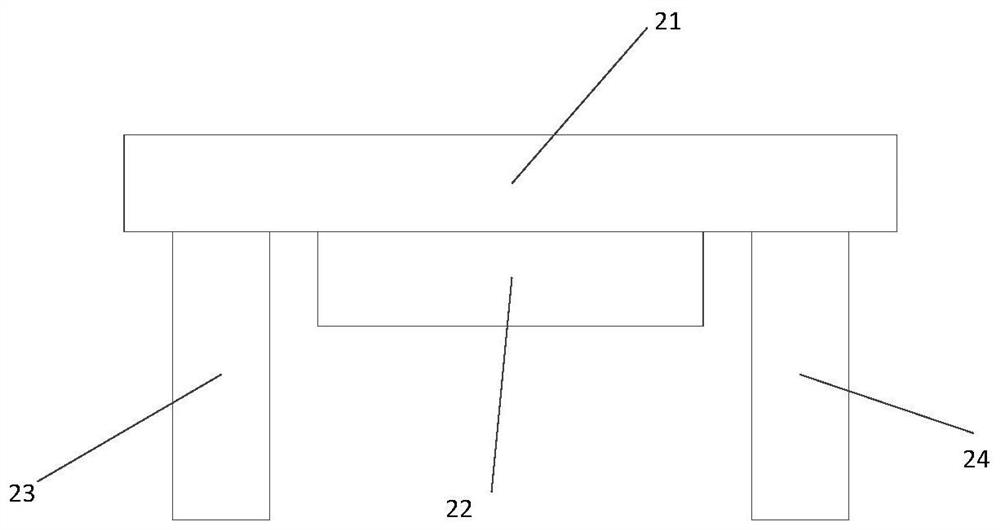

[0040] In order to illustrate the present application more clearly, the present application will be further described below in conjunction with the embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present application.

[0041] Compared with traditional screens, flexible displays are not only lighter and thinner in size, but also lower in power consumption than original devices, which helps to improve the battery life of the device. At the same time, based on its bendable and flexible characteristics, Its durability is also much higher than that of previous screens, reducing the probability of accidental damage to equipment. Therefore, the technology for flexible display screens needs to be improved day by day.

[0042] At present, the low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com