A lifting device for control engineering

A technology for controlling engineering and lifting devices, applied in the direction of lifting devices, etc., can solve the problems of inconvenient movement and inability to fully meet the needs of use, and achieve the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

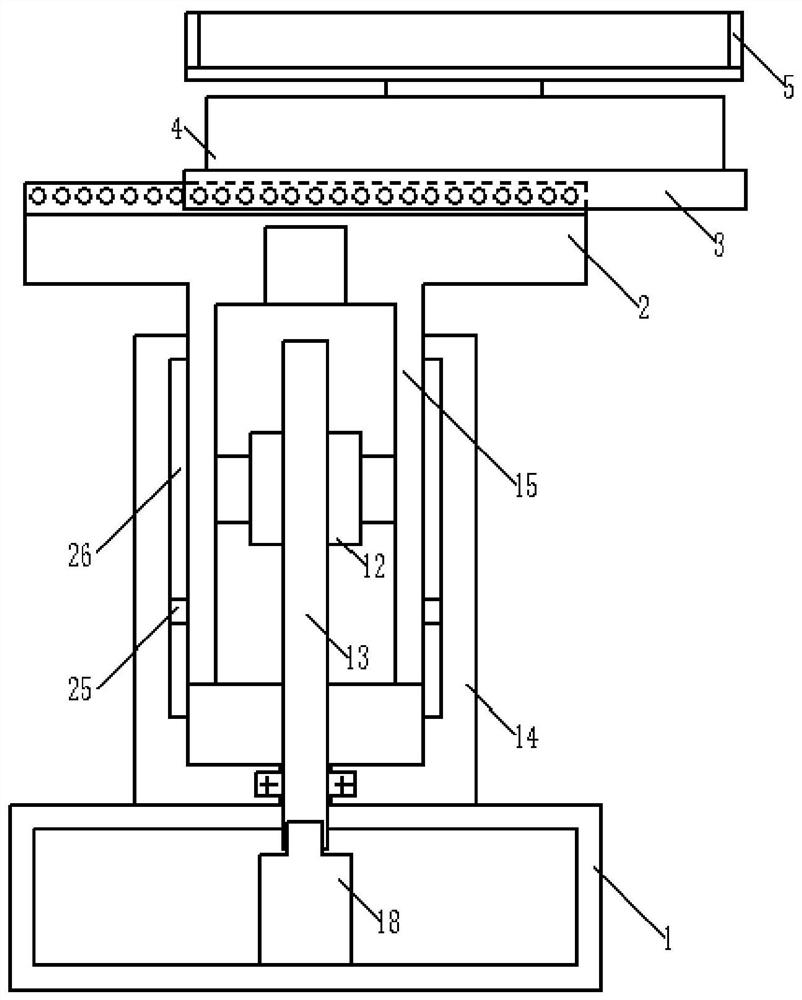

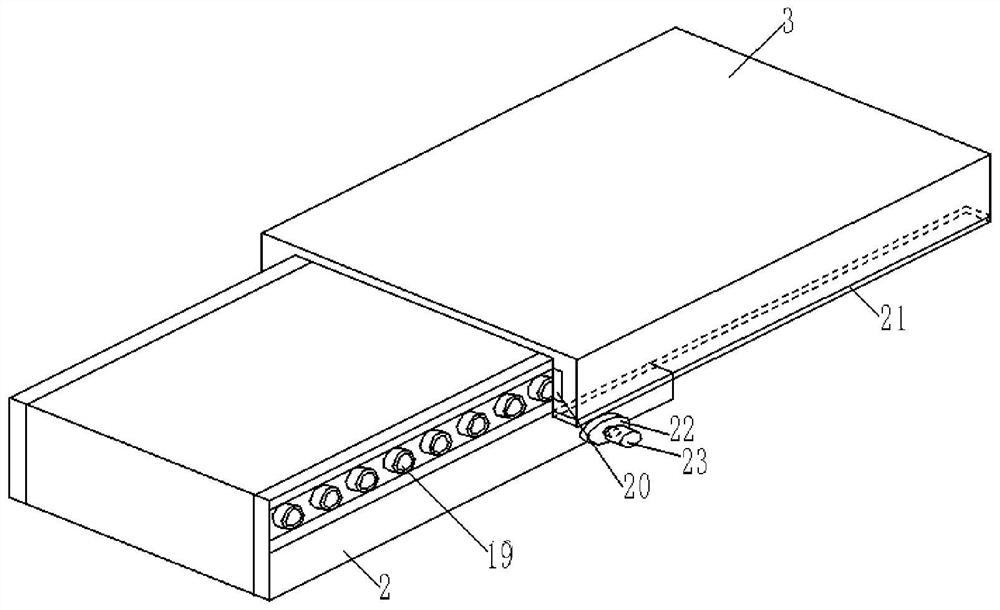

[0049] See figure 1 , is a structural schematic diagram of a lifting device for control engineering in an embodiment. Including: a base 1; a lifting mechanism, the fixed end of which is fixed on the upper surface of the base 1; a first plate body 2 connected to the output end of the lifting mechanism, and the lifting mechanism drives the first plate body 2 to rise relative to the base 1 Down; translation mechanism, its fixed end is fixed on the first plate body 2; the second plate body 3 is connected with the output end of the translation mechanism, and the translation mechanism drives the second plate body 3 along the first plate body 2 sliding left and right; the housing 4 is fixed on the upper surface of the second board 3; the intermittent rotation mechanism is located inside the housing 4 as a whole, and its fixed end is connected with the housing 4; the workbench 5 is its The upper surface is provided with control engineering equipment, which is located above the housin...

Embodiment 2

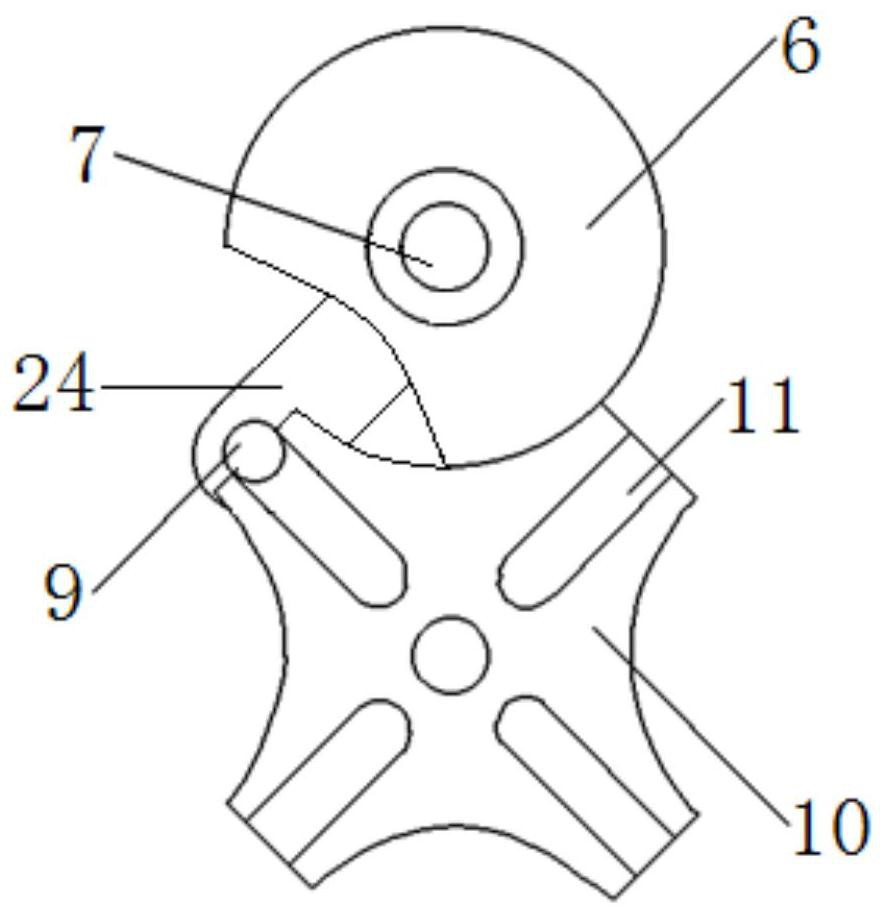

[0052]This embodiment is based on Embodiment 1, and the intermittent rotation mechanism includes: a driving dial 6, the lower surface of which is connected to the housing 4 through a plane thrust bearing, and the plane thrust bearing is clipped into a recess opened on the housing 4. In the groove; the first rotating shaft 7 runs through the driving dial 6 and is fixedly connected with the driving dial 6; the upper and lower ends of the first rotating shaft 7 are respectively connected to the housing 4 through a bearing; the first motor 8 , is connected with one end of the first rotating shaft 7, and the first motor 8 is fixed inside the housing 4; the round pin 9 is connected with the driving dial 6 through the connecting rod 24; the driven sheave 10 is connected with the The driving dial 6 is matched, and the driven sheave 10 is provided with a radial groove 11 that is matched with the round pin 9; Fixedly connected, the upper and lower ends of the second rotating shaft 17 ar...

Embodiment 3

[0055] This embodiment is based on Embodiment 1, and the lifting mechanism includes: a column 14, which is a hollow shell structure fixed on the upper surface of the base 1; a lifting column 15, which is also a hollow shell structure, is sleeved on the column 14, and is slidingly connected with the column 14 through a sliding assembly; the screw 13 is placed longitudinally inside the lifting column 15, the lower end of the screw 13 passes through the column 14 and the base 1 in turn, and the lower end of the screw 13 Connected with the column 14 through a bearing; the nut 12 is sleeved on the outside of the screw 13 and screwed with the screw 13, and the nut 13 is also connected with the lifting column 15 through the connecting plate 16; the second motor 18, whose output The shaft is connected with the lower end of the screw rod 13 , and the second motor 18 is fixed inside the base 1 .

[0056] Further, the sliding assembly includes: a sliding block 25 fixed on the left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com