Droplet jetting device and method

A liquid droplet spraying and liquid droplet technology, applied in printing and other directions, can solve the problems of reduced efficiency, high maintenance cost, liquid leakage, etc., and achieve the effects of ensuring sealing and stability, low maintenance cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

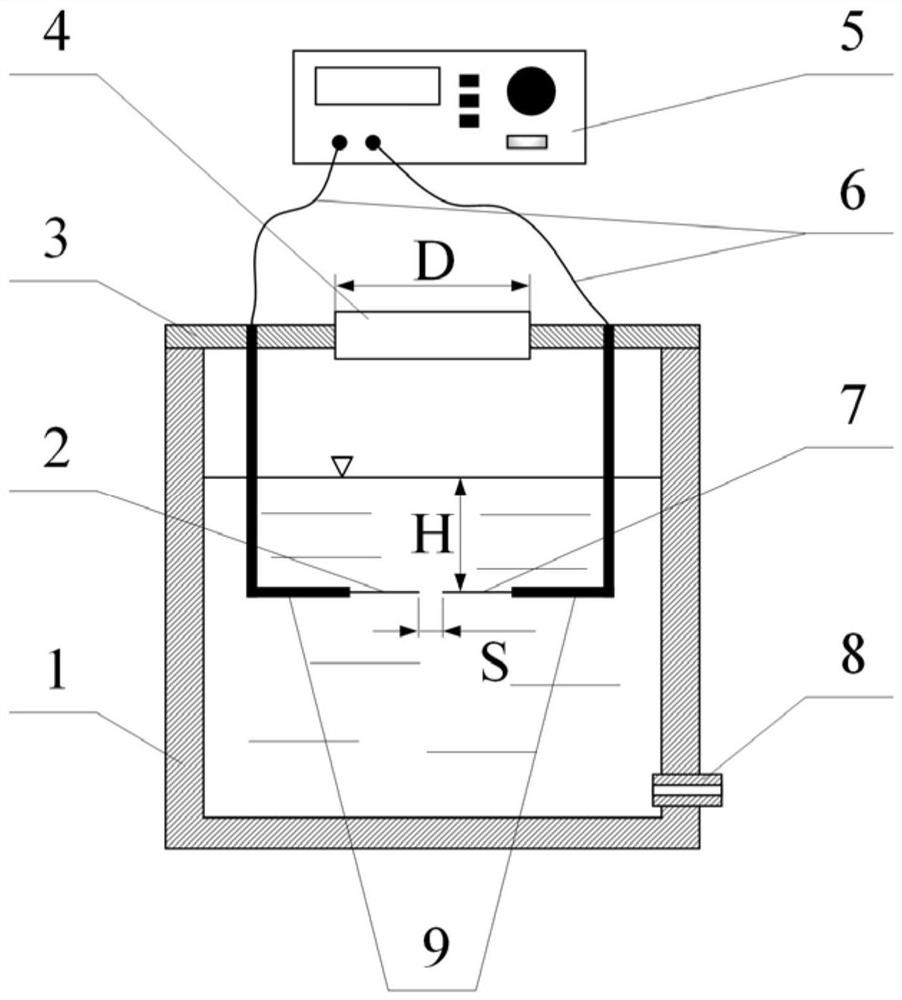

[0021] The present invention provides a droplet spraying device and method, which will be further described below in conjunction with the accompanying drawings.

[0022] Such as figure 1 Shown is a schematic diagram of the structure of the droplet ejection device, in which the droplet ejection device includes a cavitation generator, a cavity, a cover plate and a nozzle; the cavitation generator is arranged on the cover plate 3, and the cavitation generator is controlled by the power controller , L-shaped electrode holder, positive electrode and negative electrode; the cavitation generator generates cavitation in the cavity; the liquid surface breaking jet caused by the cavitation behavior near the liquid surface completes the launch and delivery of droplets; the bottom of cavity 1 There is a liquid injection port 8, which is used to control the inflow or outflow of liquid; the upper end of the cavity 1 is provided with a cover plate 3 and a nozzle 4, and the cover plate is use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com