Pneumatic tire

A technology of pneumatic tires and tires, applied to tire parts, tire tread/tread pattern, vehicle parts, etc., can solve the problems of pull-out variation, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

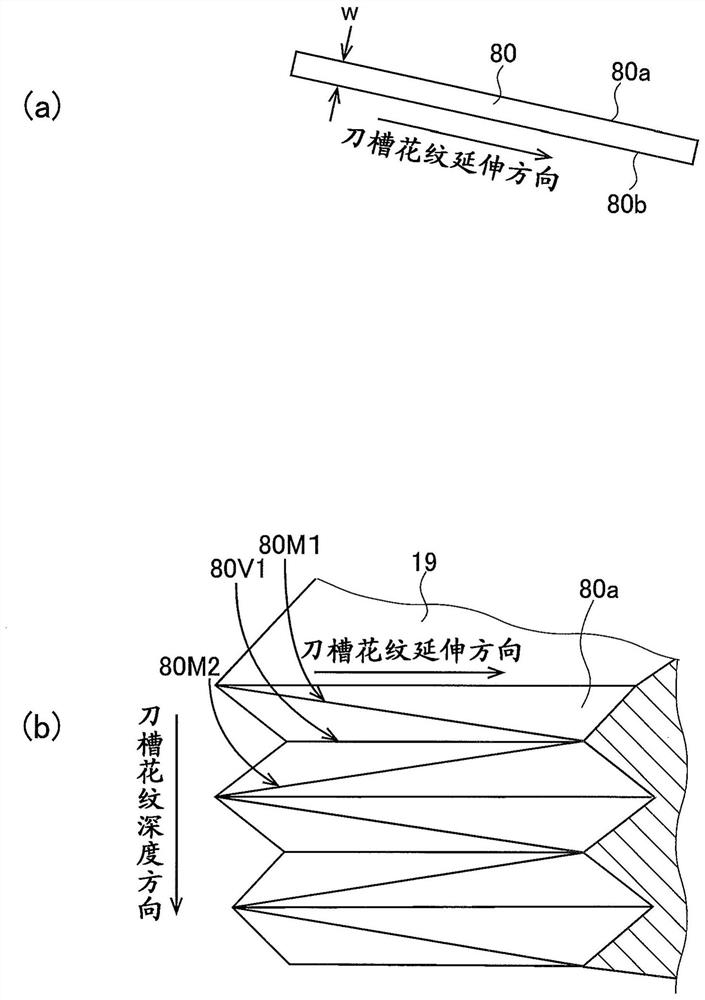

[0135] In Example 3, the sipes provided in the regions of the side land portions 64b, 65b are set so that the two opposing sipe wall surfaces are parallel and the sipe wall surfaces extend on a straight line in the sipe depth direction. For the flat sipe, the sipe provided in the region of the side land portions 64a and 65a in Example 6 is also set so that the two facing sipe wall surfaces are parallel and the sipe wall surface is at the depth of the sipe. A conventional sipe of a flat surface extending in a straight line in the direction.

[0136] [Table 1]

[0137]

[0138] [Table 2]

[0139]

[0140] It can be seen that all of Examples 1 to 6 have improved steering stability and high-speed durability compared with the conventional examples. From this, it can be seen that the rigidity against the falling deformation and the shearing deformation of the land portion provided with the sipe 80 can be appropriately imparted to the land portion.

[0141] From the comparis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com