Titanium nanosheet/graphene-based heating film

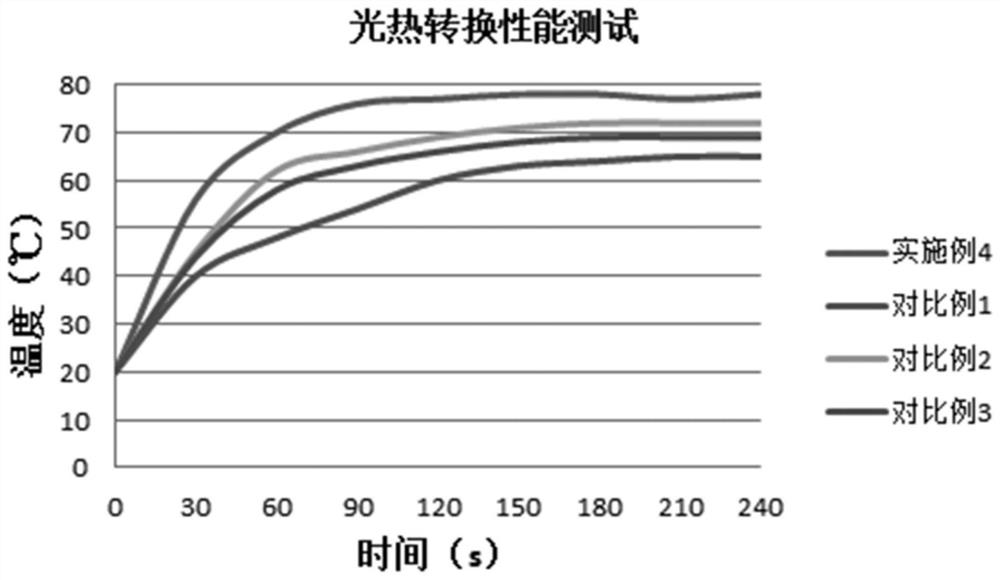

An alkenyl-based heating film, titanium nanotechnology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor circuit continuity, poor heat resistance, large resistance, etc. The effect of preventing leakage and high efficiency of photothermal conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

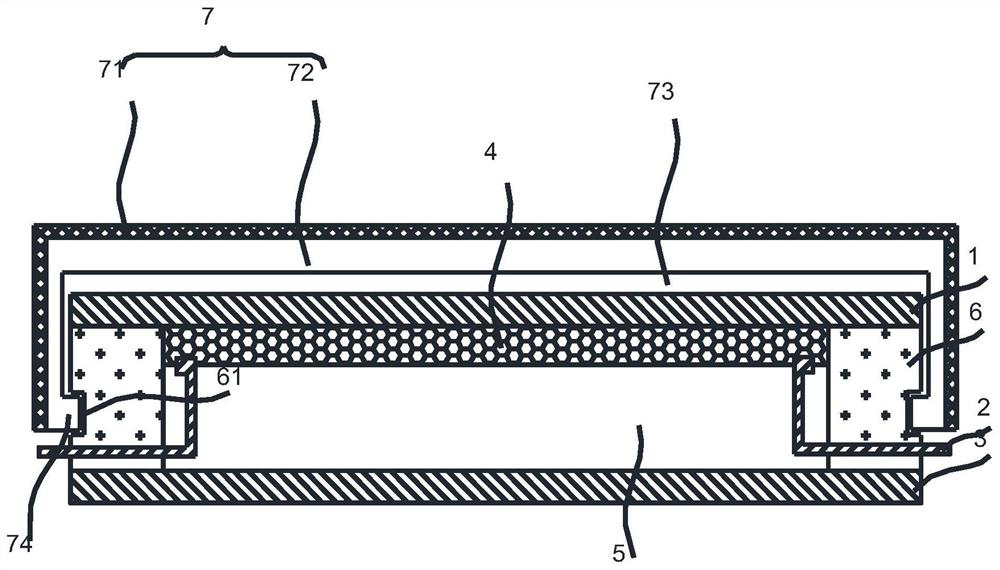

Image

Examples

preparation example Construction

[0057] A preparation method of titanium nanosheet / graphene-based fiber membrane, comprising the following steps:

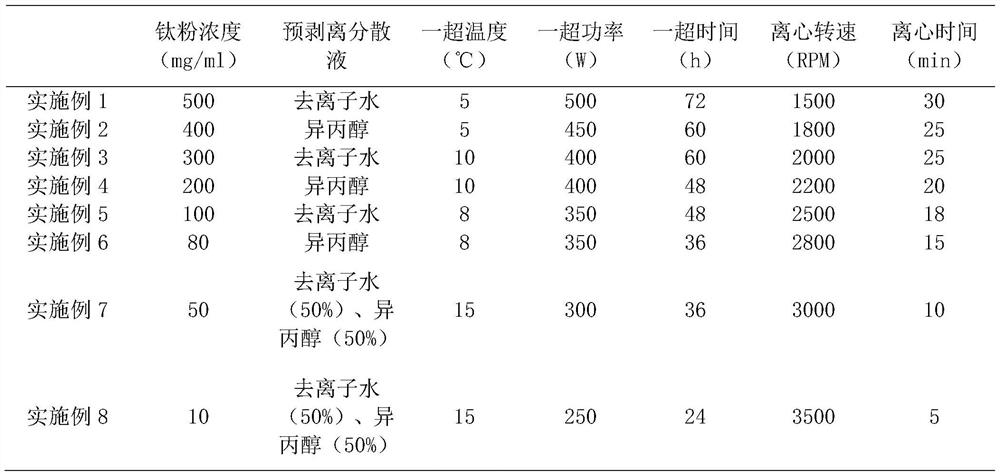

[0058] Prepare the pre-stripping dispersion of titanium powder: provide titanium powder and add in the pre-stripping dispersion, the kind of pre-stripping dispersion (the pre-stripping dispersion in embodiment 7 and embodiment 8 is the mixture of deionized water and Virahol The mass ratio is 1:1 mixed pre-stripping dispersion) and the concentration of titanium powder in the pre-stripping dispersion is shown in Table 1. The pre-stripping dispersion liquid added with titanium powder is subjected to a first-level water bath ultrasonic, wherein the temperature of the first-level water bath ultrasonic (the first-level water bath ultrasonic is referred to as "one super", the temperature here is the temperature value set by the water bath, the actual The temperature of the water bath will fluctuate to a certain extent), the power and the ultrasonic time are shown in Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com