Photoconductive switch with electrode pre-set solder and manufacturing method thereof

A photoconductive switch and electrode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as charge concentration, and achieve the effect of improving the withstand voltage and reliability, and improving the reliability of electrode connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

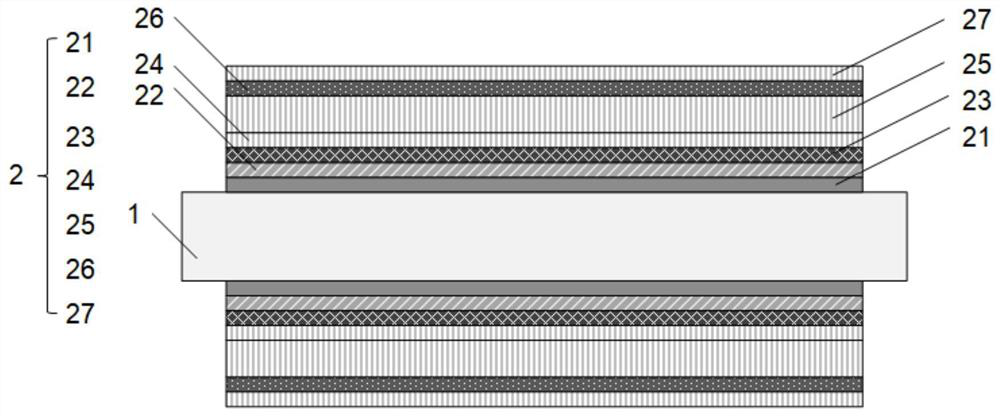

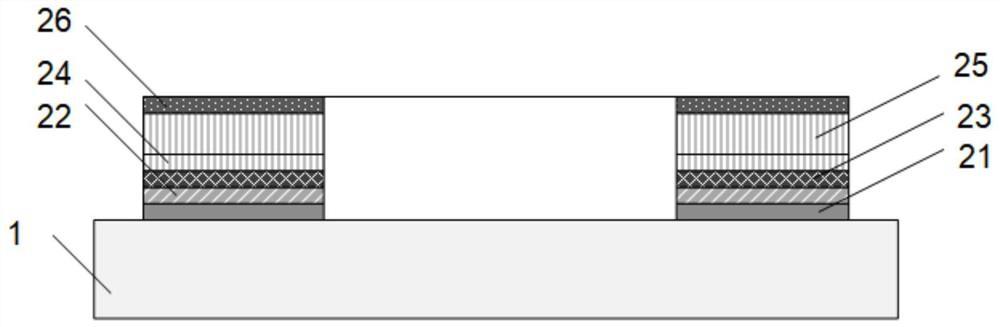

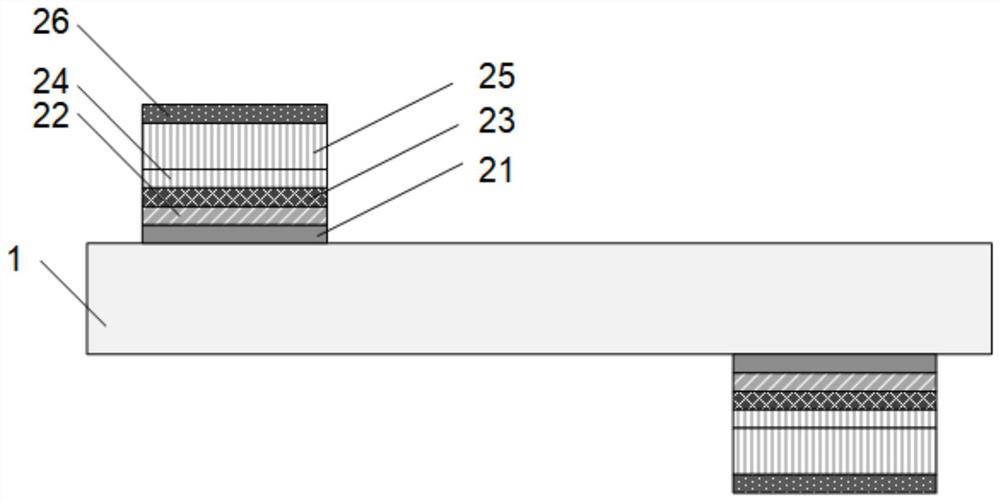

[0045] see figure 1 As shown, this embodiment provides a photoconductive switch with electrodes pre-prepared with solder, including a silicon carbide substrate 1 and two electrodes 2:

[0046] The silicon carbide substrate 1 includes opposite first surfaces and second surfaces. In this embodiment, the silicon carbide substrate 1 is a semiconductor silicon carbide wafer doped with carriers;

[0047] Two electrodes 2 are arranged on the first surface and / or the second surface of the silicon carbide substrate 1, and the electrodes 2 include a Ni layer 21, a TiW layer 22, a Pt layer 23, a first Au layer 24, and a second Au layer stacked in sequence. 25 and Sn layer 26, and the Ni layer 21 is located on the side close to the silicon carbide substrate 1, wherein the mass ratio of the second Au layer 25 to the Sn layer 26 is 8:2, so the second Au layer 25 and the Sn layer 26 are processed by heat treatment After forming Au80Sn20 to form a eutectic solder layer;

[0048] In this exa...

Embodiment 2

[0052] see Figure 4 to Figure 10 As shown, based on the same inventive concept, the present invention also provides a method for preparing a photoconductive switch with electrode preset solder, comprising the following steps:

[0053] S1: providing a silicon carbide wafer 1 and processing the silicon carbide wafer 1 to a required size;

[0054] S2: Processing mask tooling 3, see Figure 5 Image 6 , Figure 7 As shown, the mask tooling 3 includes a base 31 and a mask steel plate 32 stacked up and down. A number of chip placement grooves 311 consistent with the size and thickness of the silicon carbide wafer 1 are provided on the base 31. According to the shape of the electrode 2, the mask steel plate 32 An electrode groove 321 is provided at a position corresponding to the wafer placement groove 311;

[0055] In this embodiment, the base 31 and the mask steel plate 32 are square, and each of the four corners of the base 31 is provided with a base screw hole 312, and each ...

Embodiment 3

[0065] This embodiment is a specific application of Embodiment 2. This embodiment provides a method for preparing a photoconductive switch with electrodes pre-prepared with solder, and this embodiment takes the structure of electrodes facing opposite sides as an example to illustrate, including the following steps :

[0066] 1. Select a carrier-doped semiconductor silicon carbide wafer 1 and process it to the required size. In this embodiment, the silicon carbide wafer 1 is processed to 10mm×10mm×1mm. The side of the silicon carbide wafer 1 fed into the laser needs to be polished ;

[0067] 2. Process the mask tooling 3, first process the base 31, and cut out a wafer placement groove 311 of 10mm×10mm×1mm in size consistent with the wafer size and thickness on the base 31, and a plurality of wafer placement grooves 311 can be processed on the base 31, In this way, multiple wafers can be processed in the same batch, which is more efficient than photolithography; positioning pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com