Underwater non-blasting demolition construction method for reserved rock bank

A construction method and non-blasting technology, applied in water conservancy projects, hydropower, hydropower stations, etc., can solve the problem of low rock mass quality requirements, achieve the effect of small demolition works, accurate positioning, and prevention of over-excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

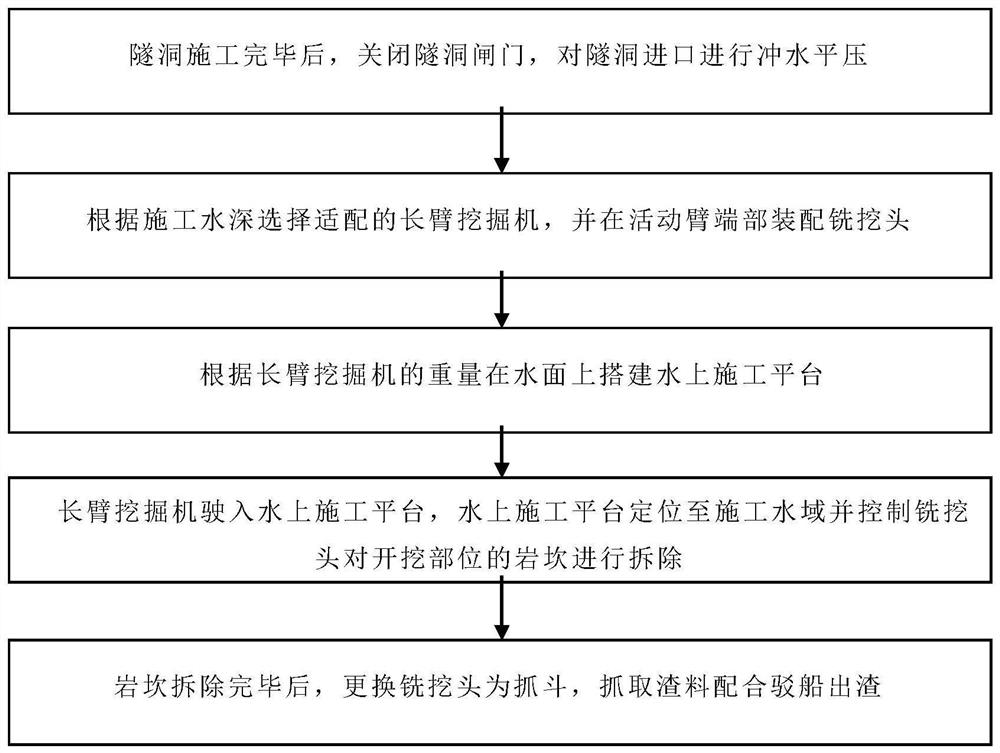

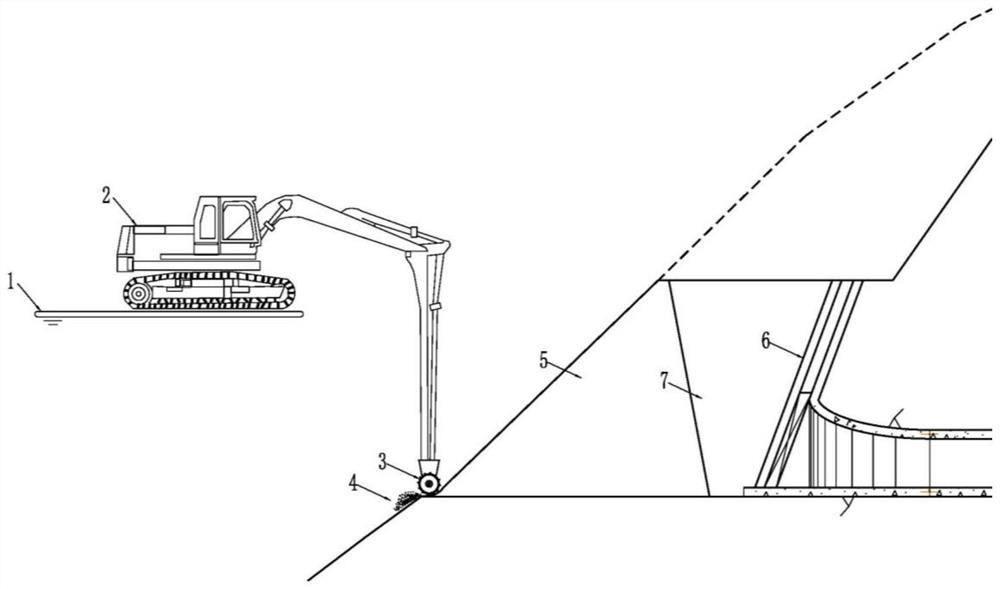

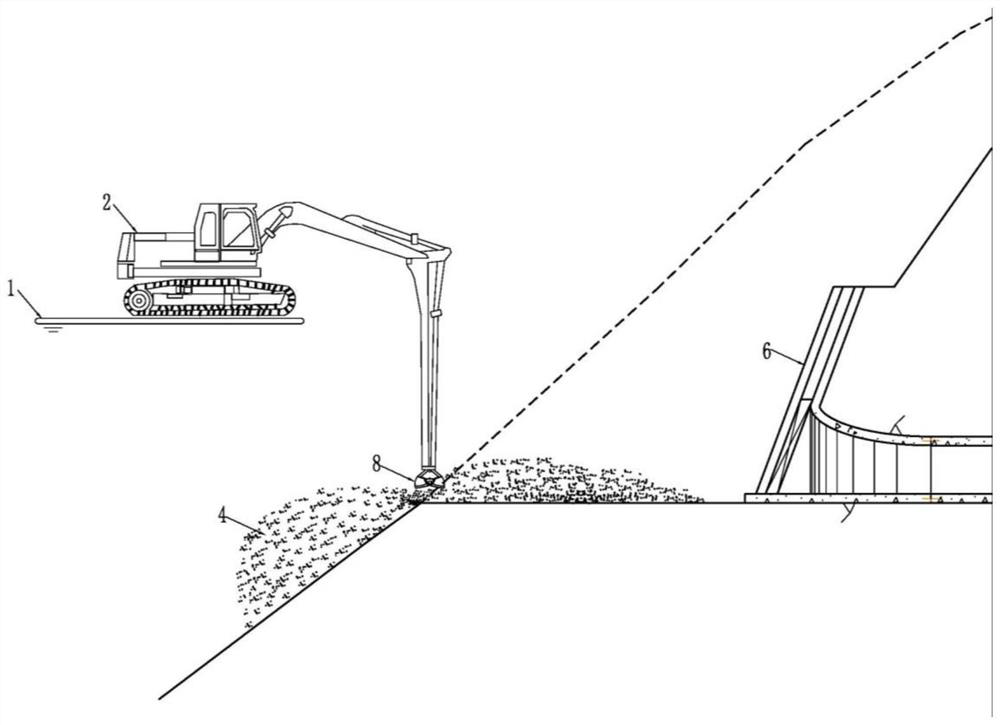

[0029] Such as Figure 1-3 As shown, a construction method for underwater non-explosive demolition of reserved rock sills includes the following steps:

[0030] Step 1. After the tunnel construction is completed, the tunnel entrance gate is closed, and the tunnel entrance shaft is filled with water and pressurized;

[0031] Step 2, selecting a suitable long-arm excavator 2 according to the construction water depth, and assembling a milling head 3 at the end of the movable arm of the long-arm excavator 2;

[0032] Step 3, build a water construction platform 1 for carrying the long-arm excavator 2 on the water surface according to the weight of the long-arm excavator 2;

[0033] Step 4, the long-arm excavator 2 drives into the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com