One-time pouring construction process for ramp double-lane separation curb and main body structure

A technology of main structure and construction technology, which is applied in the field of one-time pouring construction technology of ramp two-lane road dents and main structure, can solve the problems of difficult construction and long construction period of road dents, and achieves high foundation strength, improved rigidity, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

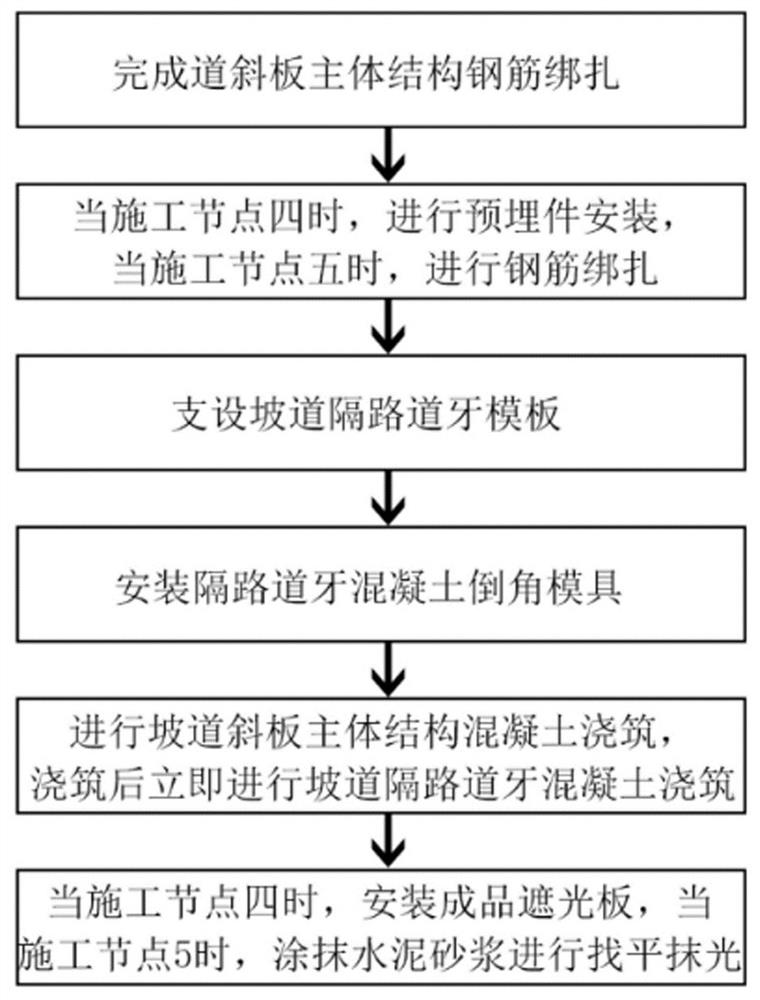

[0050] On-site construction steps:

[0051] Binding of the main reinforcement of the slope slab first;

[0052] Position and set out the reinforced concrete slab with a width of 100mm;

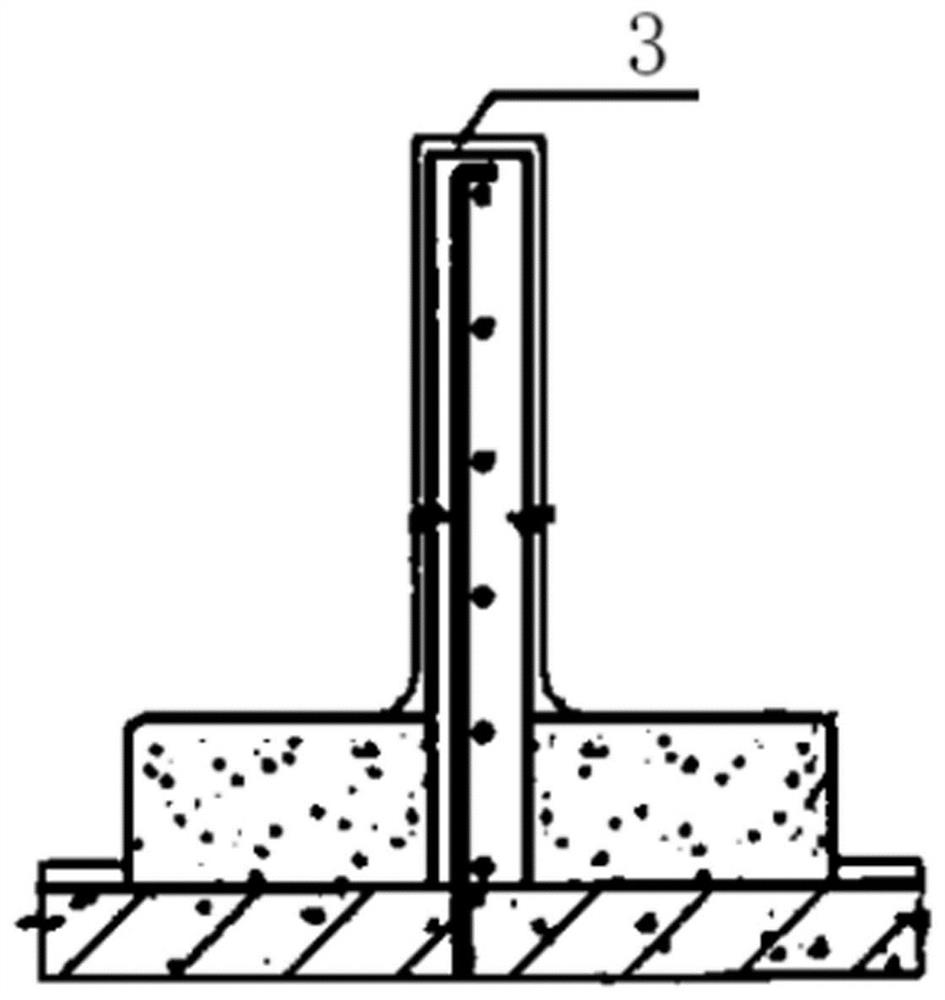

[0053] To install reinforced concrete slab reinforcement, first install the vertical main reinforcement Φ10@200, and then bind the horizontal reinforcement 6Φ10;

[0054] Supporting reinforced concrete slab formwork for ramps and curbs (spending formwork construction);

[0055] Positioning and laying out of the foundation of the ramp and the corner of the ramp and supporting the formwork (formwork hanging construction);

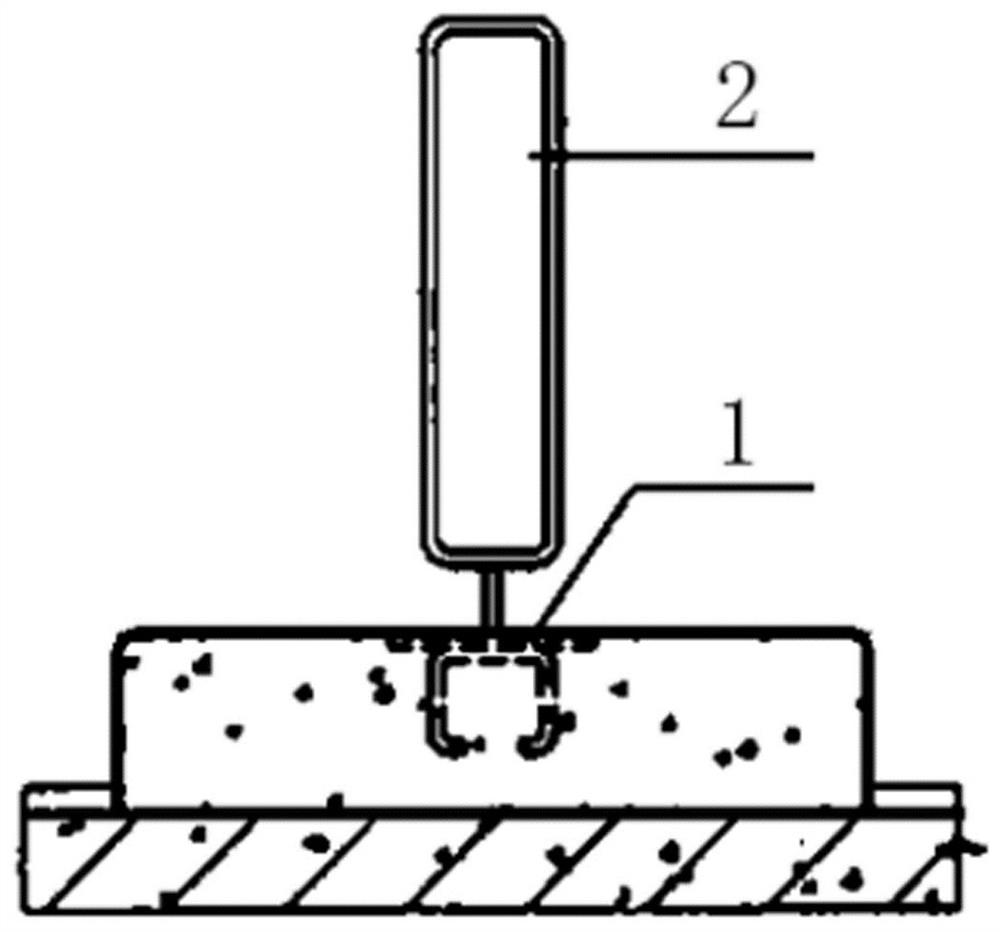

[0056] Install the concrete chamfering mold of the road tooth foundation;

[0057] Carry out the concrete pouring of the main structure of the slope slab, and then immediately carry out the foundation pouring of the corbels separated by the road; then pour the reinforced concrete slabs of the curbs separated by the road;

[0058] Carry out the demolition of the foundation f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com