A production method for false twisting and texturing of yarn and a detection method for tail joints in the process of false twisting and texturing of yarn

A production method and yarn technology, applied in jointing devices, spinning machines, textiles and papermaking, etc., can solve the problems of forgetting to lift the head, relying on manual work, and prone to errors, so as to avoid misrecording or omission and reduce production cost, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

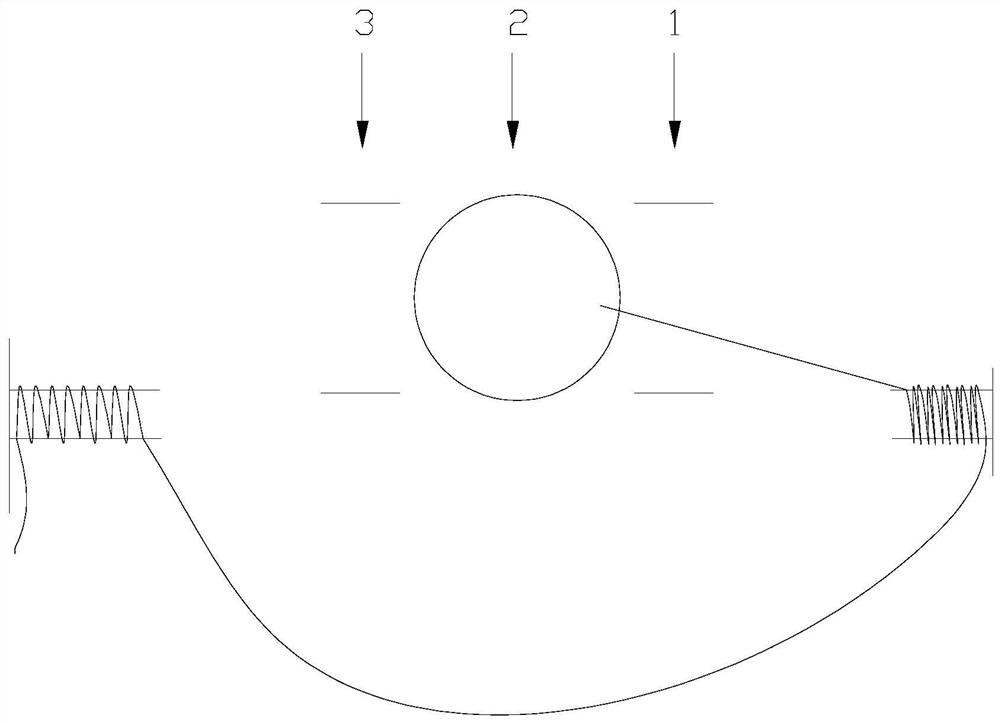

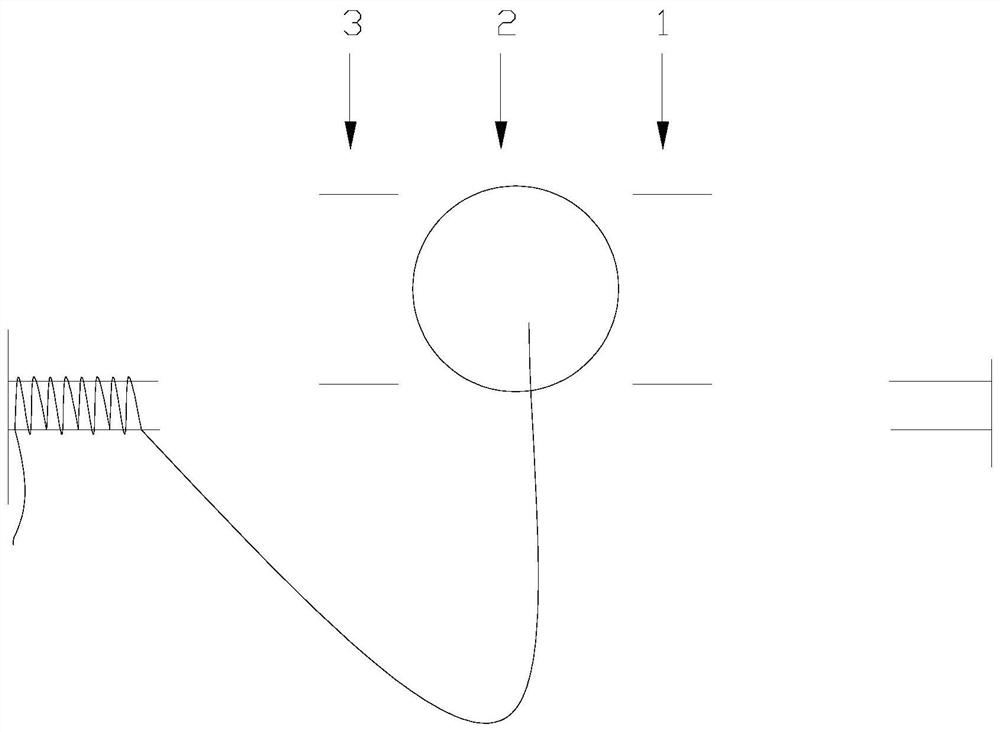

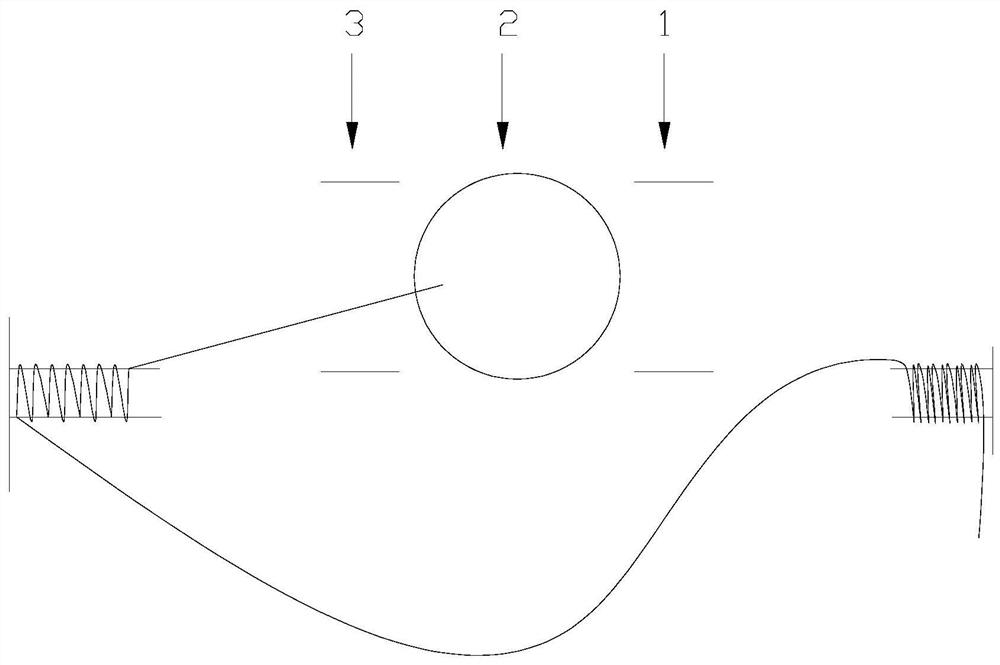

[0030] like Figure 1-3 As shown, in this example, polyester pre-oriented yarn (POY for short) is used as raw yarn in polyester yarn, and then DTY (drawn textured yarn, usually called polyester low elastic yarn) is made by stretching and false twisting processing as an example. The continuous production method comprises the following steps: passing a plurality of yarn coils whose heads and tails are connected in sequence through a false twisting and elasticizing process; making the yarns of the plurality of yarn coils connected at their heads and tails in sequence pass through a detection channel Then perform the false twisting and elasticizing process, wherein, the detection channel collects the position change information of switching a yarn spool that has finished running the yarn to the next yarn spool whose head and tail are connected in sequence, and collects the information. Each of the described position transformation information identifies an over-tail connector;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com