High-entropy ceramic material with excellent tribological properties and preparation method thereof

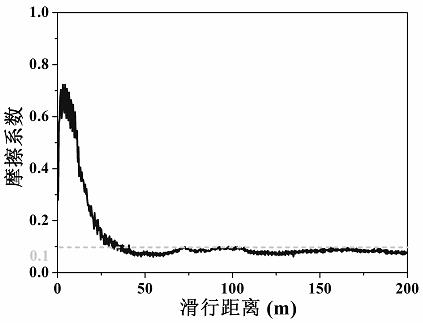

A ceramic material and tribological technology, applied in the field of high-entropy ceramic materials and its preparation, can solve the problems of very little research on tribological properties, and achieve the effects of favorable sintering, simple preparation process, and easy densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

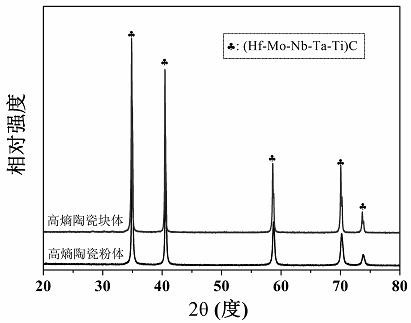

[0033] Example 1 A high-entropy ceramic material with excellent tribological properties, the material is in the form of a block, its composition is (Hf-Mo-Nb-Ta-Ti-)C, and it is made from the following raw materials in mass percentage: HfO 2 21.2%, MoO 3 14.5%, Nb 2 o 5 13.4%, Ta 2 o 5 22.3%, TiO 2 8.0% and graphite powder 20.6%.

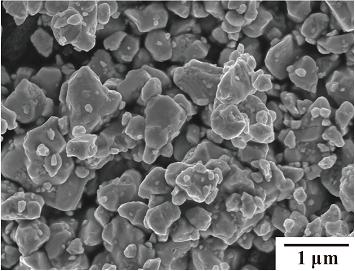

[0034] The preparation method of the high-entropy ceramic material: firstly weigh each raw material according to the proportion, put each raw material in a ball mill, then add anhydrous ethanol 0.25 times its mass to the mixed raw material, mix evenly, dry, pass through Sieve to obtain mixed powder with a particle size of 5-20 μm; put the mixed powder into a graphite mold, place it in a spark plasma sintering furnace and undergo spark plasma sintering. ℃ / min, the sintering temperature is 1750 ℃, the pressure is 15 MPa, and the holding time is 30 min. After sintering, the sintered product was pulverized in a high-energy ball mill to obtain a h...

Embodiment 2

[0035] Example 2 A high-entropy ceramic material with excellent tribological properties, the material is in the form of a block, its composition is (Hf-Mo-Nb-Ta-Ti-)C, and it is made from the following raw materials in mass percentage: HfO 2 21.9%, MoO 3 15.0%, Nb2 o 5 13.8%, Ta 2 o 5 23.0%, TiO 2 8.3% and graphite powder 18.0%.

[0036] The preparation method of the high-entropy ceramic material: firstly weigh each raw material according to the proportion, and place each raw material in a ball mill, then add anhydrous ethanol 0.35 times its mass to the mixed raw material, mix evenly, dry, pass through Sieve to obtain mixed powder with a particle size of 5-20 μm; put the mixed powder into a graphite mold and place it in a spark plasma sintering furnace for spark plasma sintering. The sintering conditions refer to a vacuum degree below 0.08 Pa and an average heating rate of 150°C / min, the sintering temperature is 1850°C, the pressure is 5MPa, and the holding time is 20 mi...

Embodiment 3

[0037] Example 3 A high-entropy ceramic material with excellent tribological properties, the material is in the form of a block, its composition is (Hf-Mo-Nb-Ta-Ti-)C, and it is made from the following raw materials in mass percentage: HfO 2 21.5%, MoO 3 14.7%, Nb 2 o 5 13.6%, Ta 2 o 5 22.7%, TiO 2 8.1% and graphite powder 19.4%.

[0038] The preparation method of the high-entropy ceramic material: firstly weigh each raw material according to the proportion, and place each raw material in a ball mill, then add anhydrous ethanol 0.30 times its mass to the mixed raw material, mix evenly, dry, pass through Sieve to obtain mixed powder with a particle size of 5-20 μm; put the mixed powder into a graphite mold and place it in a spark plasma sintering furnace for spark plasma sintering. / min, sintering temperature 1800 ℃, pressure 10MPa, holding time 25 min. After sintering, the sintered product is pulverized in a high-energy ball mill to obtain a high-entropy ceramic powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com