A non-clogging microporous aeration system

A microporous aeration and non-clogging technology, which is applied in the direction of water aeration, special treatment targets, chemical instruments and methods, etc., can solve the problem that the working area of multi-row microporous aeration tubes cannot be fully utilized and the sludge cannot be completely prevented from entering , It is not easy to disassemble the internal sludge cleaning and other problems, so as to achieve the effect of good sealing, enhanced agitation and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

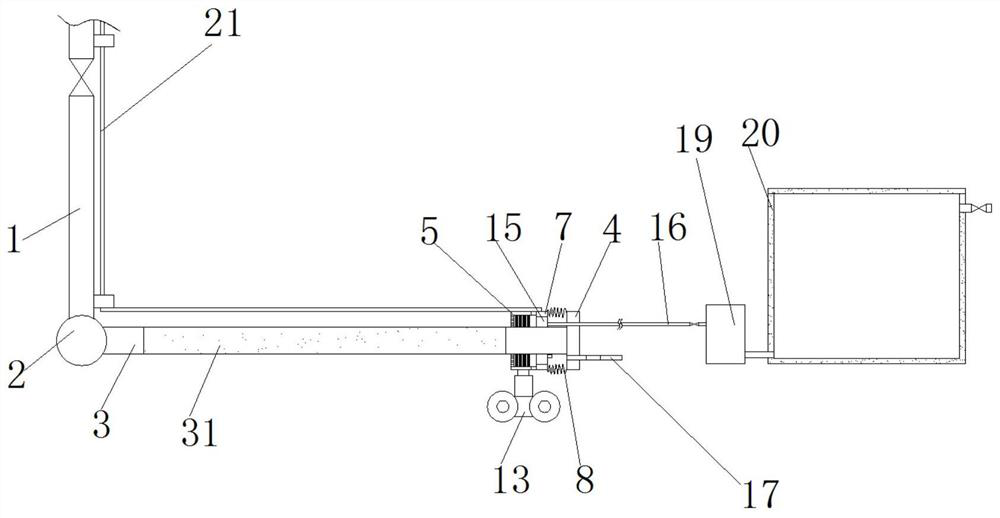

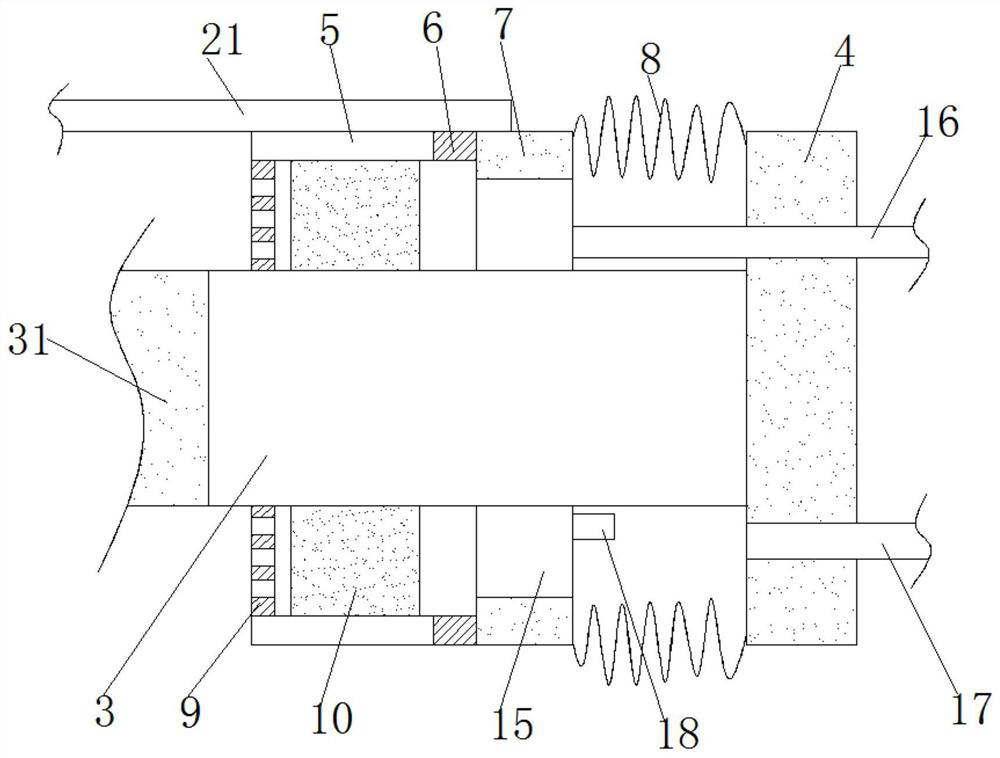

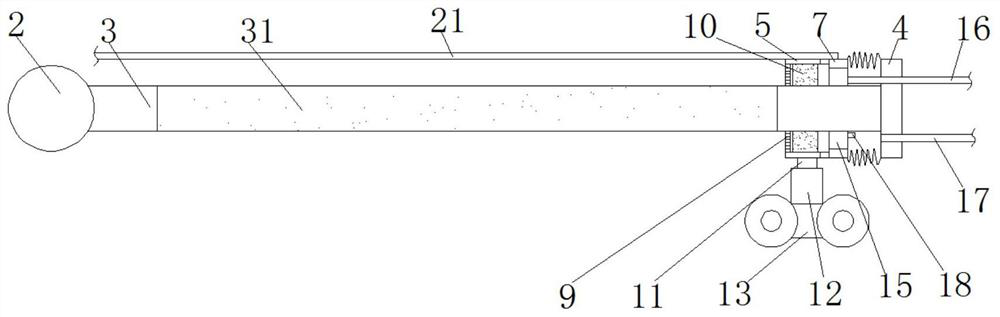

[0030] refer to Figure 1-7 , a non-blocking microporous aeration system, comprising an air inlet pipe 1, the upper end of the air inlet pipe 1 is connected with the outlet end of the blower or the compressed air pipe, the lower end of the air inlet pipe 1 is fixedly connected with a distribution pipe 2, the distribution pipe 2 is Pipe 2 is connected with evenly distributed aeration pipes 3, such as Figure 7 As mentioned above, the number of aeration pipes 3 on a single distribution pipe 2 is generally 2 to 12, and one end of the aeration pipe 3 away from the distribution pipe 2 is provided with a sealing plate 4, and the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com