Production system and production method of high-purity phosphoric acid

A high-purity phosphoric acid and production system technology, applied in the field of phosphorus pentoxide, can solve problems such as difficulty in obtaining high-purity phosphorus pentoxide vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

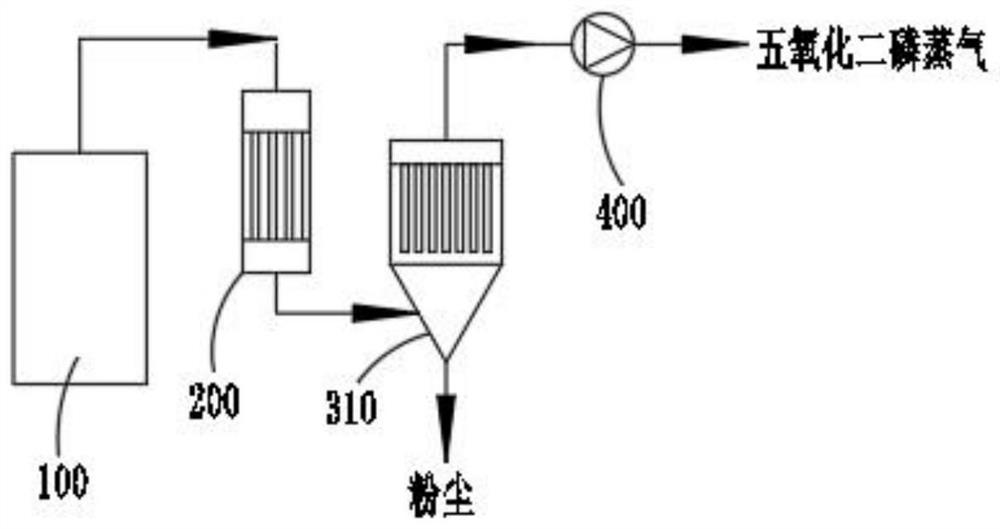

[0061] figure 1 It is a structural schematic diagram of the production equipment of phosphorus pentoxide vapor in this embodiment.

[0062] Such as figure 1 As shown, the production equipment of phosphorus pentoxide vapor includes:

[0063] Reduction and oxidation furnace 100, in which the raw material containing phosphate rock undergoes a reduction and oxidation reaction to generate a first gas with a temperature of 700-900°C containing phosphorus pentoxide vapor and dust;

[0064] The heat exchange unit 200, the heat exchange unit 200 outputs the second gas with a temperature of 365-500°C after processing the first gas, specifically, it can output the second gas with a temperature of 365°C, 380°C, 450°C or 500°C ;

[0065] A high-temperature filter unit 310, the high-temperature filter unit 310 intercepts the dust in the second gas and then outputs a dust content of ≤10mg / Nm 3 Phosphorus pentoxide vapor, specifically can output dust content ≤ 10mg / Nm 3 、≤8mg / Nm 3 、≤6mg...

Embodiment 2

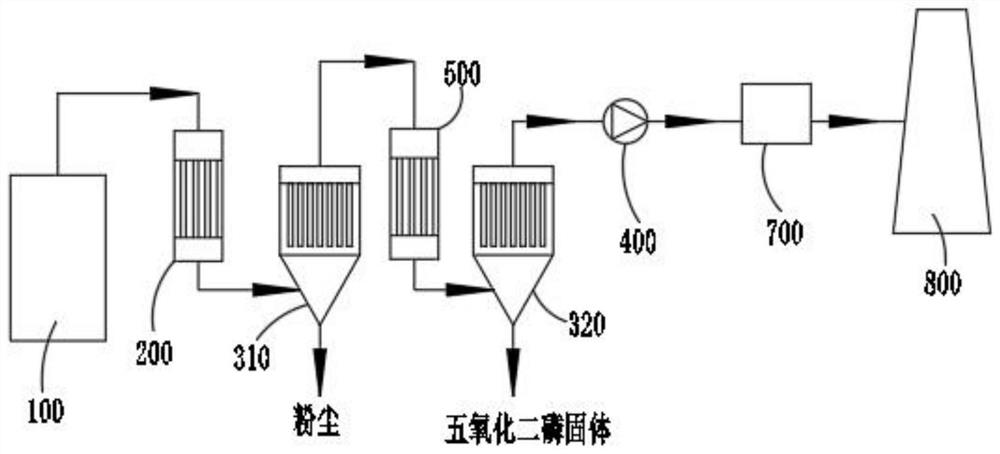

[0068] figure 2 It is a structural schematic diagram of the production system of phosphorus pentoxide solid in this embodiment.

[0069] Such as figure 2 Shown, the production system of phosphorus pentoxide solid comprises:

[0070] Reduction and oxidation furnace 100, in which the raw material containing phosphate rock undergoes a reduction and oxidation reaction to generate a first gas with a temperature of 700-900°C containing phosphorus pentoxide vapor and dust;

[0071] The heat exchange unit 200, the heat exchange unit 200 outputs the second gas with a temperature of 365-500°C after processing the first gas, specifically, it can output the second gas with a temperature of 365°C, 380°C, 450°C or 500°C ;

[0072] A high-temperature filter unit 310, the high-temperature filter unit 310 intercepts the dust in the second gas and then outputs a dust content of ≤10mg / Nm 3 Phosphorus pentoxide vapor, specifically can output dust content ≤ 10mg / Nm 3 、≤8mg / Nm 3 、≤6mg / Nm 3...

Embodiment 3

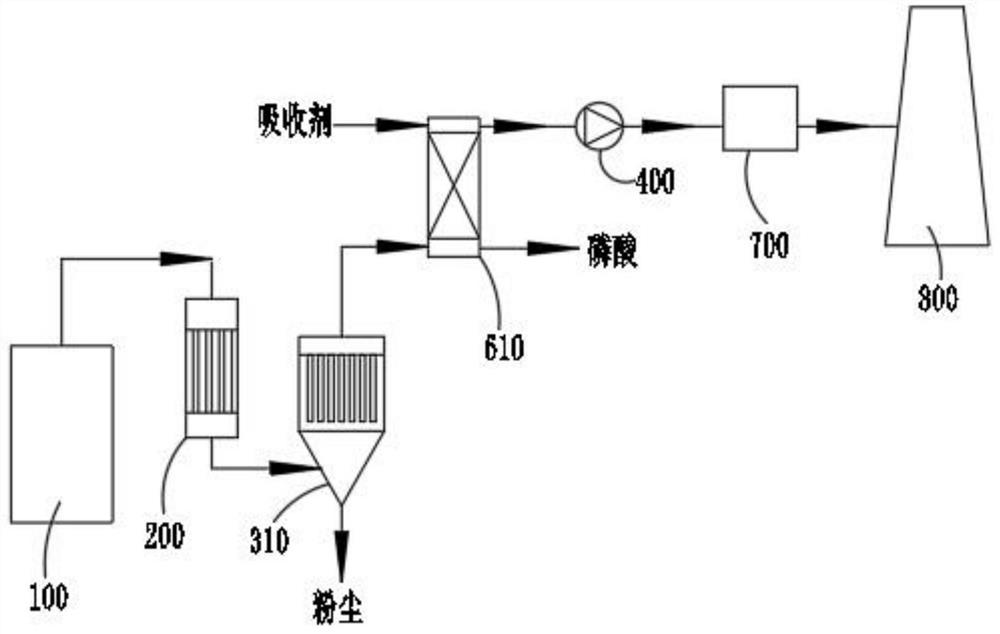

[0078] image 3 It is a structural schematic diagram of the phosphoric acid production system of this embodiment.

[0079] Such as image 3 As shown, the phosphoric acid production system includes:

[0080] Reduction and oxidation furnace 100, in which the raw material containing phosphate rock undergoes a reduction and oxidation reaction to generate a first gas with a temperature of 700-900°C containing phosphorus pentoxide vapor and dust;

[0081] The heat exchange unit 200, the heat exchange unit 200 outputs the second gas with a temperature of 365-500°C after processing the first gas, specifically, it can output the second gas with a temperature of 365°C, 380°C, 450°C or 500°C ;

[0082] A high-temperature filter unit 310, the high-temperature filter unit 310 intercepts the dust in the second gas and then outputs a dust content of ≤10mg / Nm 3 Phosphorus pentoxide vapor, specifically can output dust content ≤ 10mg / Nm 3 、≤8mg / Nm 3 、≤6mg / Nm 3 、≤5mg / Nm 3 、≤4mg / Nm 3 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com