Oil cylinder pulley type winch

A hoist and pulley technology, which is applied in the direction of hoisting devices, cranes, portable lifting devices, etc., can solve the problems of endangering the life safety of on-site workers, difficulty in installing small and medium-sized hoists, and occupying a large space, so as to avoid overweight hoisting, The effect of simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

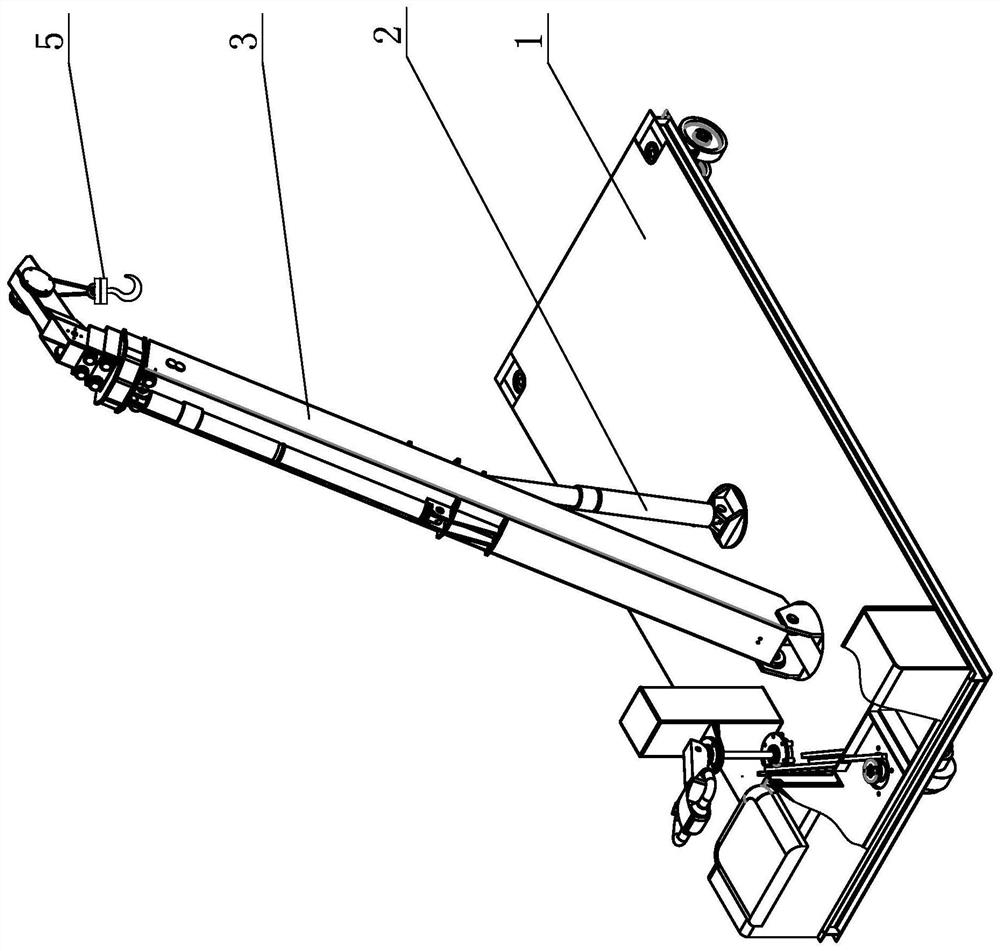

[0045] like Figure 5 As shown, the cylinder pulley winch of the present invention includes a boom assembly 3 . The hoist main body 4 is installed inside the boom assembly 3 . A drive cylinder 35 is installed on the outside of the boom, and the drive cylinder 35 provides power for the expansion and contraction of the boom. The two ends of the driving cylinder 35 are respectively hinged on two different booms of the boom assembly 3 . When the present invention is in use figure 1 As shown, the boom assembly 3 is hingedly installed on the car body 1, and a jacking cylinder 2 is also installed between the car body 1 and the boom assembly 3, and the jacking cylinder 2 can drive the boom assembly 3 to go up and down. Complete the lifting of the cargo.

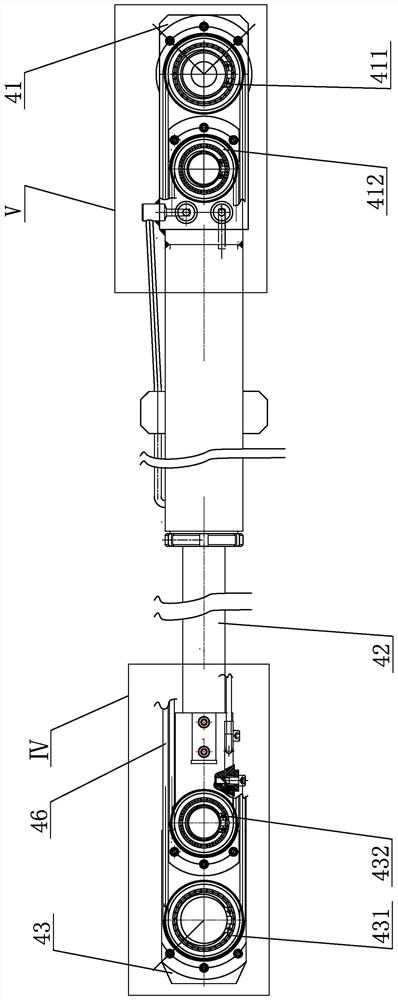

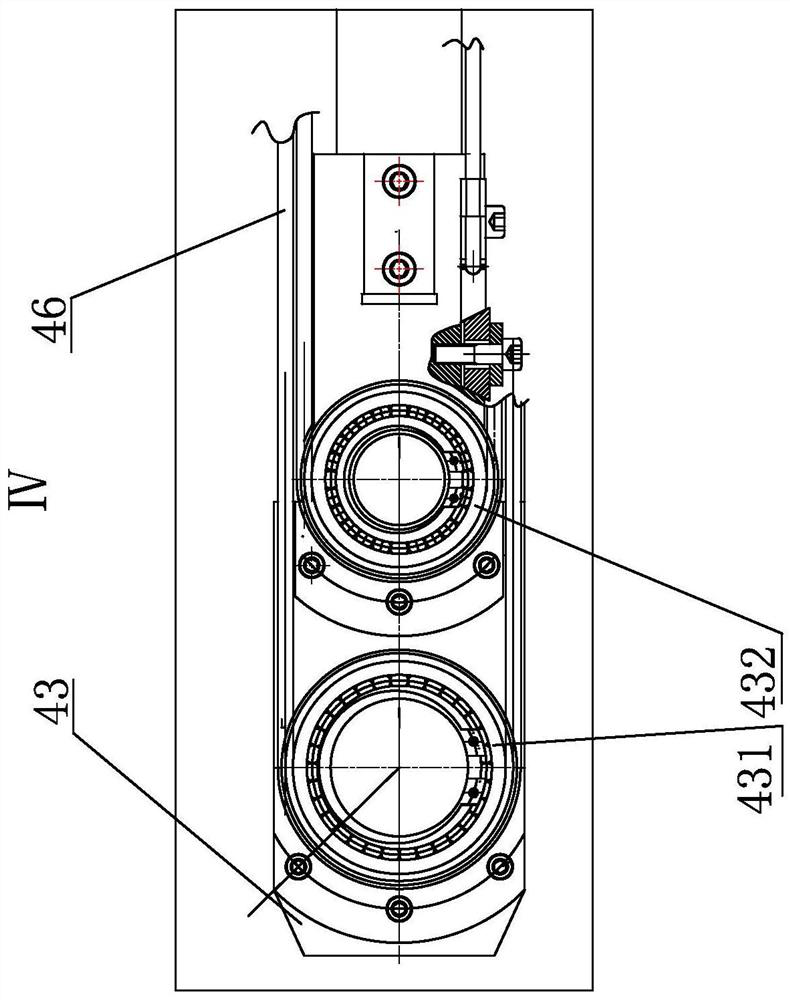

[0046] like Figure 8 As shown, the hoist main body 4 includes a first mounting plate 41, a telescopic oil cylinder 42, a second mounting plate 43 and two sets of pulley block mechanisms. The first mounting plate 41 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com