Novel material unloading equipment and novel material unloading device

A technology for unloading devices and materials, which is applied in the direction of hoisting equipment braking devices, hoisting devices, storage devices, etc., can solve the problems of difficulty in moving with the cargo, low overall efficiency, poor unloading and clean boxes, etc., to improve work efficiency and Safe operation, excellent environmental protection and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

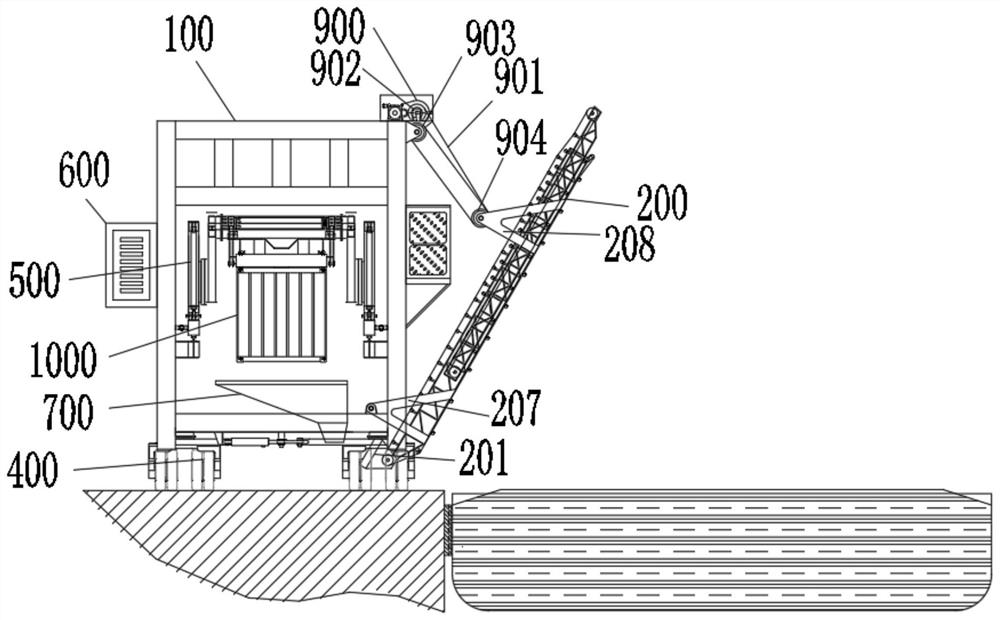

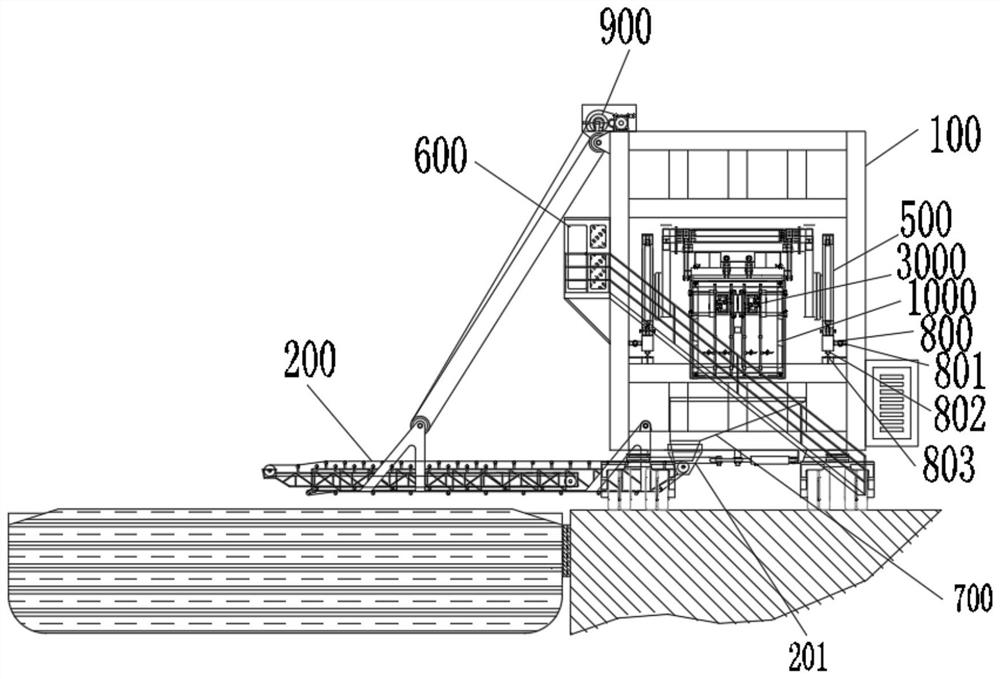

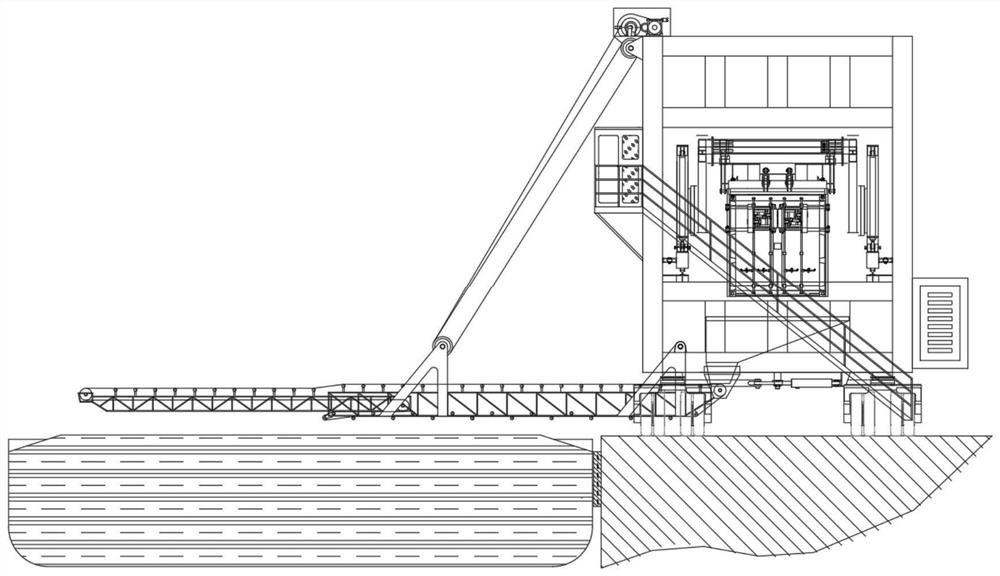

[0078] Such as Figure 1-Figure 10 As shown, a new type of material unloading device described in this embodiment includes a discharge frame 100, a discharge conveying mechanism 200, a lifting drive mechanism 900, and a discharge funnel 700. The bottom of the discharge channel of the discharge frame 100 is provided with a discharge The material funnel 700, the bottom end of the discharge conveying mechanism 200 is connected with the discharge frame 100 in rotation; The bottom end of the bottom is docked with the discharge port of the discharge funnel 700; based on this structure, the control room 600 and the stairs entering the control room can be set on the discharge frame.

[0079]In this embodiment, a driving wheel assembly is installed on the bottom of the unloading frame 100, and the driving wheel assembly includes a steering wheel assembly 300 and a driving wheel assembly 400, and the steering wheel assembly 300 and the driving wheel assembly 400 are installed on the unl...

Embodiment 2

[0086] A new type of material unloading equipment described in this embodiment includes the above-mentioned new type of material unloading device. The unloading channel of the unloading frame 100 of the new type of material unloading device is provided with a device for turning the container to a horizontal or vertical position. Shaped or inclined turning mechanism 500, and a translation drive mechanism 800 that drives the turning mechanism 500 to perform horizontal translation. The turning mechanism is provided with a spreader 110, and the end of the spreader 110 facing the discharge funnel is provided with a box for the container. The door opening and closing mechanism 3000 with the door kept open or closed, the translation drive member of the translation drive mechanism 800 is connected to the turning mechanism 500, and the translation driving mechanism 800 drives the turning mechanism to move to the discharge hopper or the container entry port of the discharge channel.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com