Bundling loading and unloading assembly line

A technology of assembly line and buffer device, which is applied to the parts of the strapping machine, strapping materials, packaging, etc., can solve the problems of loose straps and two boxes not completely overlapping, so as to avoid jitter and tilt and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

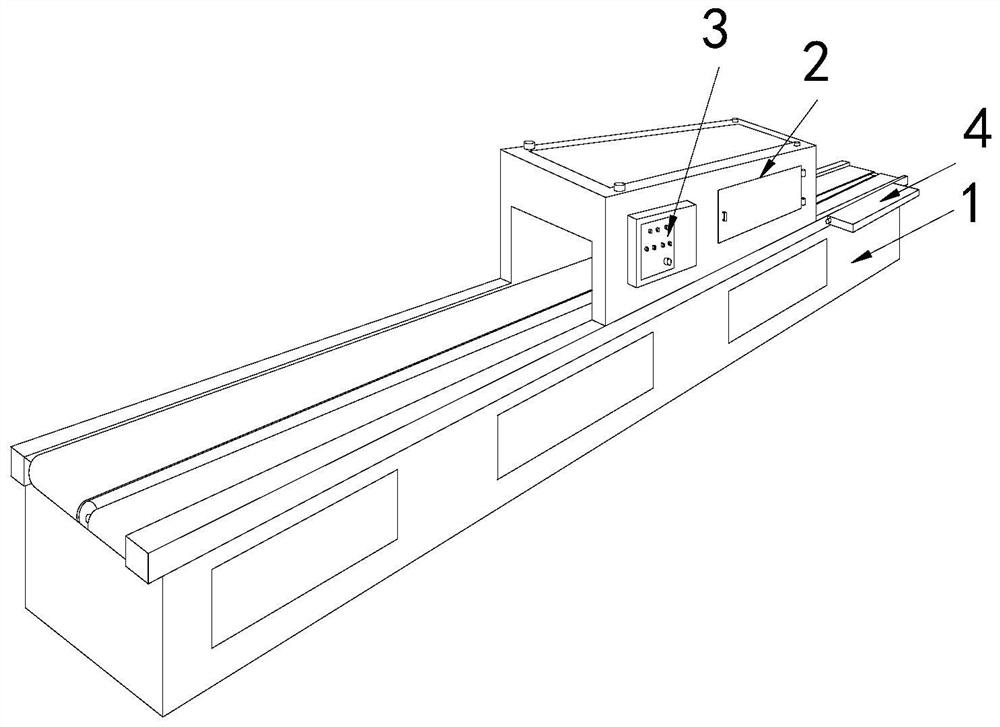

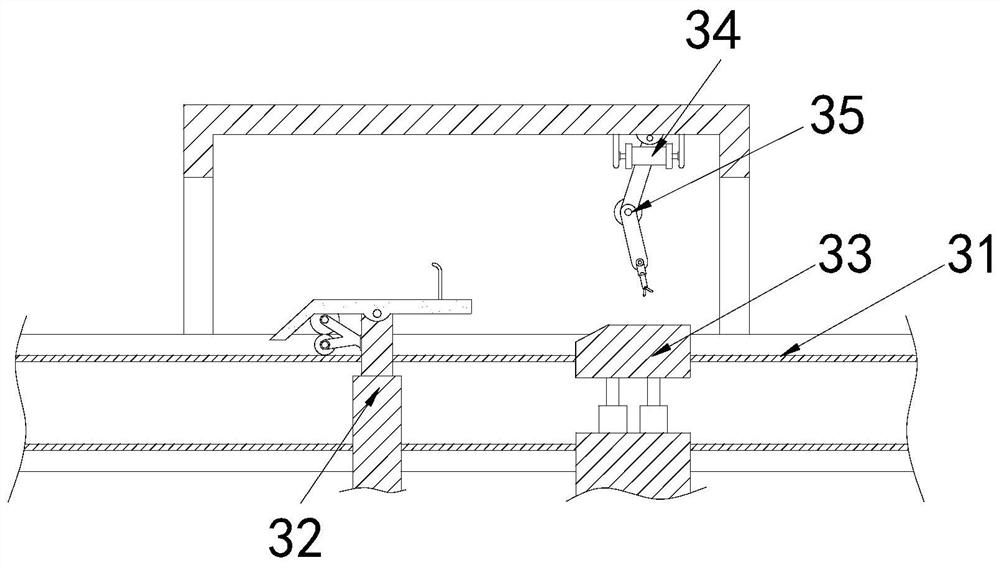

[0027] Its structure includes a main body 1, a binding box 2, a control panel 3, and a workbench 4. A binding box 2 is arranged in the middle of the top of the main body 1, and the control panel 3 is arranged at the front end of the binding box 2. The workbench 4 is located at the rear end of the main body 1, the main body 1 includes a conveyor belt 31, a stacking device 32, a binding table 33, a coil material belt 34, and a manipulator 35, the conveyor belt 31 is arranged on the top of the main body 1, and the stacking device 32 is set In the middle of the conveyor belt 31 , the strapping platform 33 is arranged at the rear end of the conveyor belt 31 , the coil material belt 34 is located directly above the stacking device 32 , and the manipulator 35 is installed on both sides of the top of the strapping box 2 .

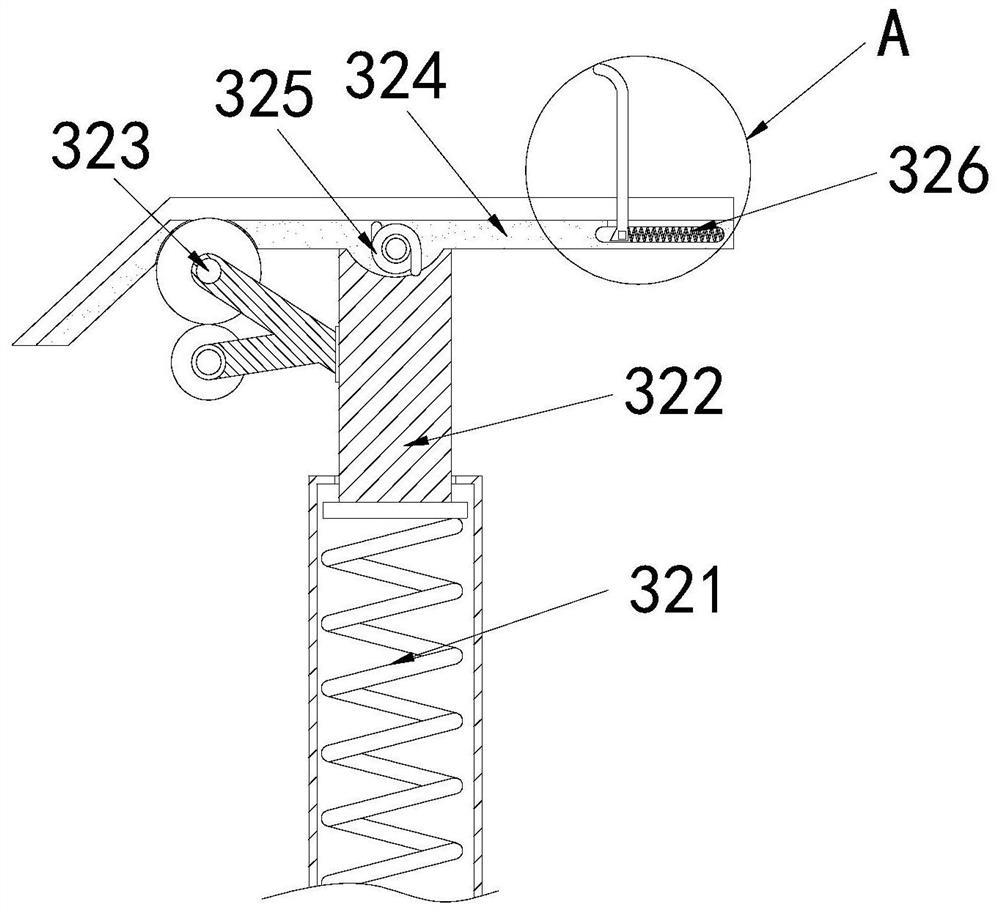

[0028] The stacking device 32 includes ...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0033] The buffer device 326 includes an empty slot b1, a buffer spring b2, and a packing plate b3. A buffer spring b2 is arranged in the empty slot b1. The packing plate b3 is engaged in the empty slot b1 and is connected with the buffer spring b2. With movable cooperation, the width of the end of the packing plate b3 is greater than the width of the port of the empty slot b1, which is beneficial for the sliding of the packing plate b3 in the empty slot b1.

[0034] The boxing board b3 includes a board body b31, an anti-drop block b32, a friction block b33, and a buffer block b34. The end of the board body b31 is provided with an anti-drop block b32, and there are more than ten friction blocks b33, and Horizontally arranged on the upper end surface of the plate body b31, two buffer blocks b34 are provided, and they are respectively located on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com