Concrete reinforcement frame welding equipment

A technology for concrete reinforcement and welding equipment, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of moving frames and high labor intensity of construction workers, and achieve the goal of reducing labor intensity, manual operation, and operation difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

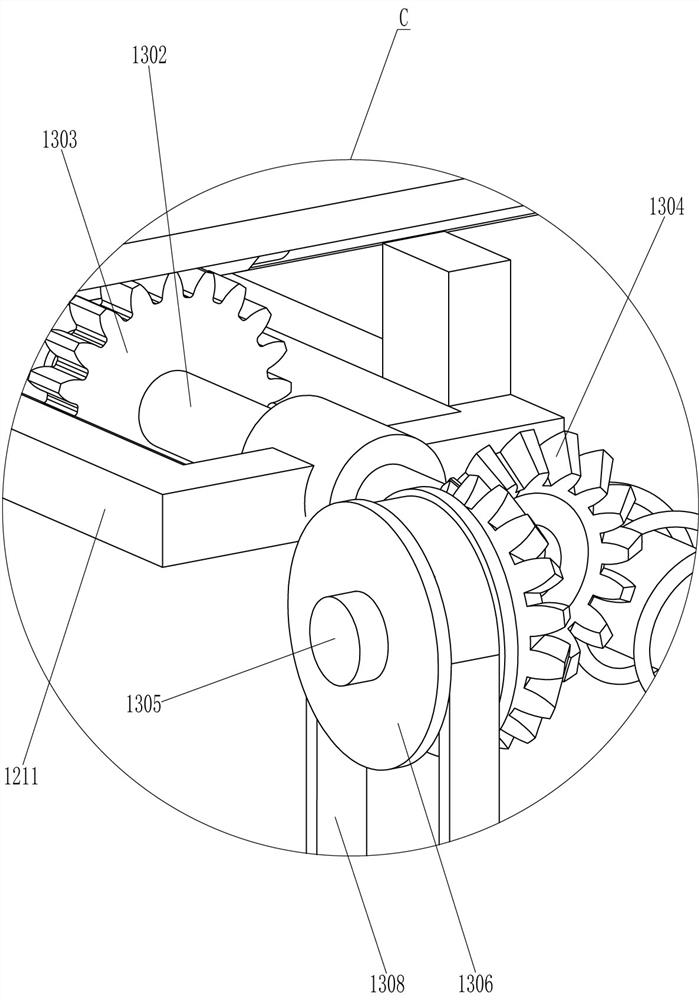

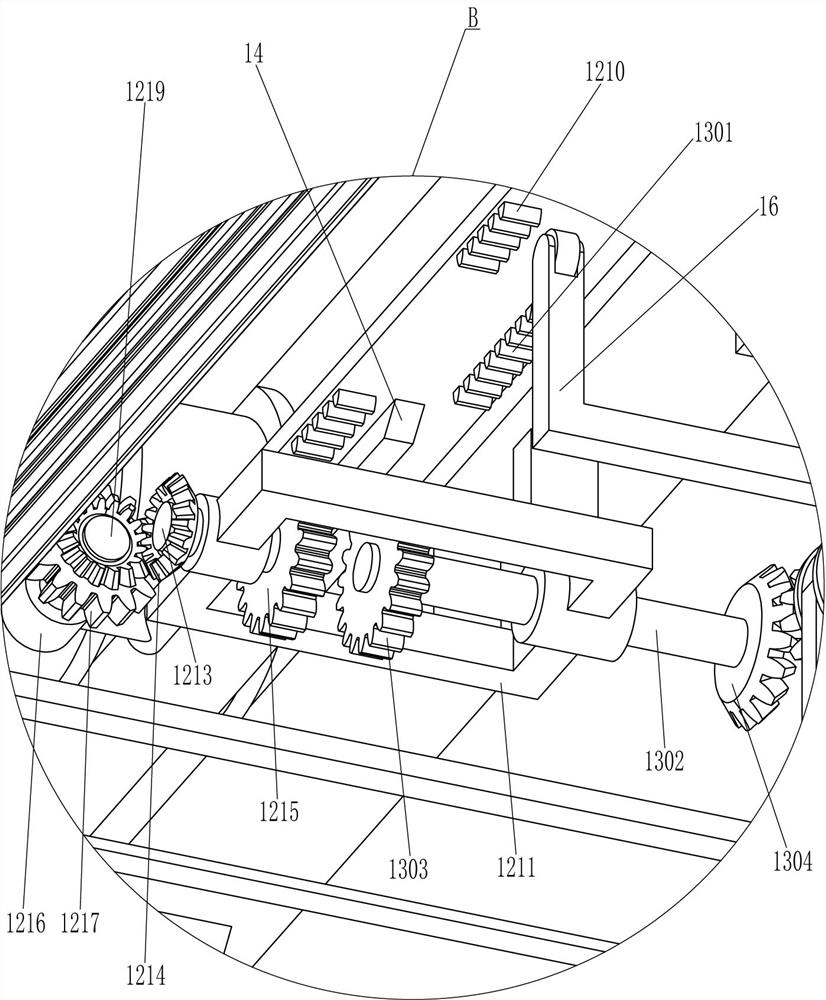

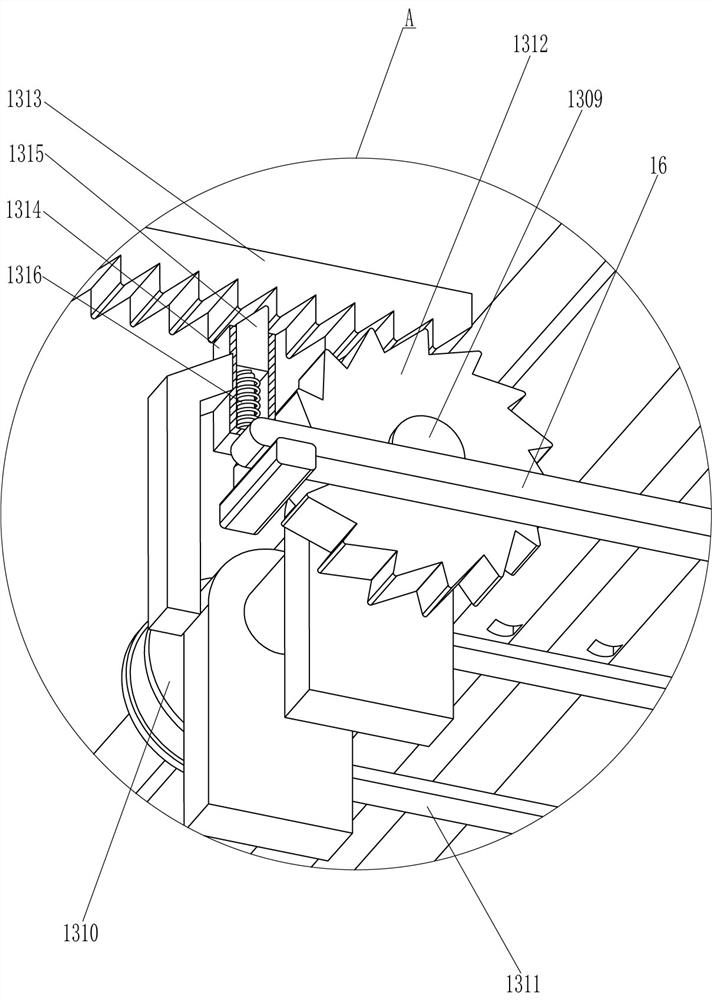

[0028] A concrete reinforcement frame welding equipment, such as Figure 1-10As shown, it includes a bottom plate 1, a guide rod 2, a placement frame 3, a first spring 4, a first support plate 5, a second support plate 6, a first support frame 7, a servo motor 8, a first transmission wheel 9, and a transmission belt. 10. Slide bar 11, spot welding assembly 12 and moving assembly 13. Guide rod 2, first support plate 5 and second support plate 6 are installed with bolts on the front and rear sides of the top of bottom plate 1. Guide rod 2 is located on the two first Between the supporting board 5 and the two second supporting boards 6, the two first supporting boards 5 are respectively connected with the two second supporting boards 6, a sliding frame 3 is provided between the two guiding rods 2, and the two guiding rods 2 The first spring 4 is sheathed on the rod 2, the right end of the first spring 4 is connected with the guide rod 2, the left end of the first spring 4 is conn...

Embodiment approach 2

[0035] On the basis of Embodiment 1, such as figure 2 , image 3 , Figure 7 , Figure 9 with Figure 10 As shown, it also includes trapezoidal strip 14, second guide sleeve 15, special-shaped rod 16 and fourth spring 17, two trapezoidal strips 14 are connected to the outside of transmission belt 10, and the second guide sleeve 15 is connected to the right side of the bottom plate 1 top. Two guide sleeves 15 are positioned at the right side of the third bracing frame 1307, and the second guide sleeve 15 is provided with a special-shaped rod 16, and the wedge-shaped rod 1315 and the drive belt 10 are all in contact with the special-shaped rod 16, and the special-shaped rod 16 is covered with a fourth spring 17. The bottom ends of the four springs 17 are connected with the second guide sleeve 15 , and the top ends of the fourth springs 17 are connected with the special-shaped rod 16 .

[0036] When the servo motor 8 rotates clockwise, the first transmission wheel 9 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com