Water gap sealing structure, filter element and water purification equipment

A technology of sealing structure and nozzle, applied in the field of nozzle sealing structure, filter element, and water purification equipment, can solve the problems of easy damage of seals, avoid wear problems, facilitate pressing operation, and simplify waterway design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

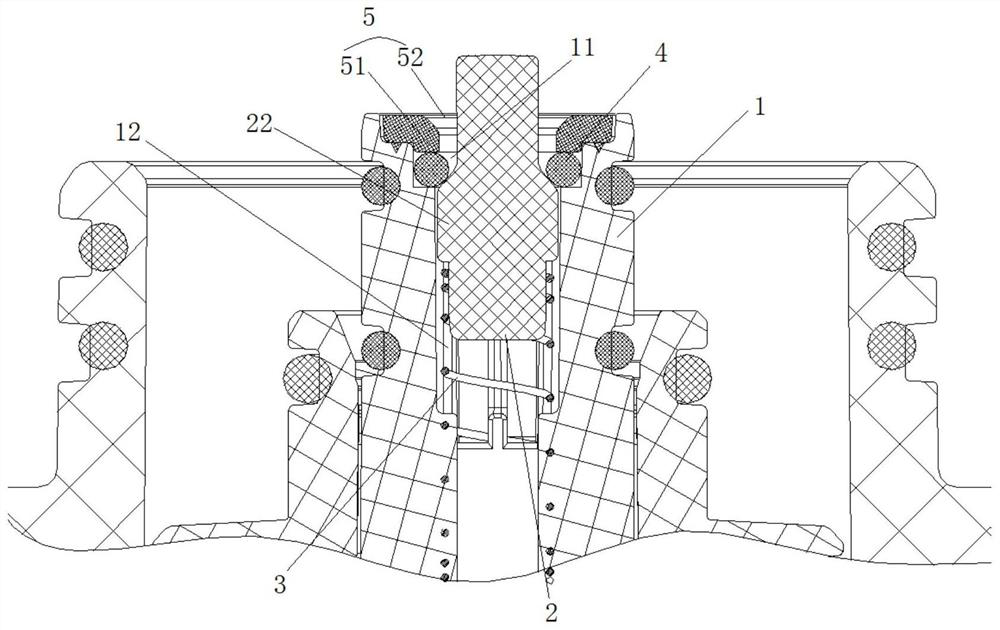

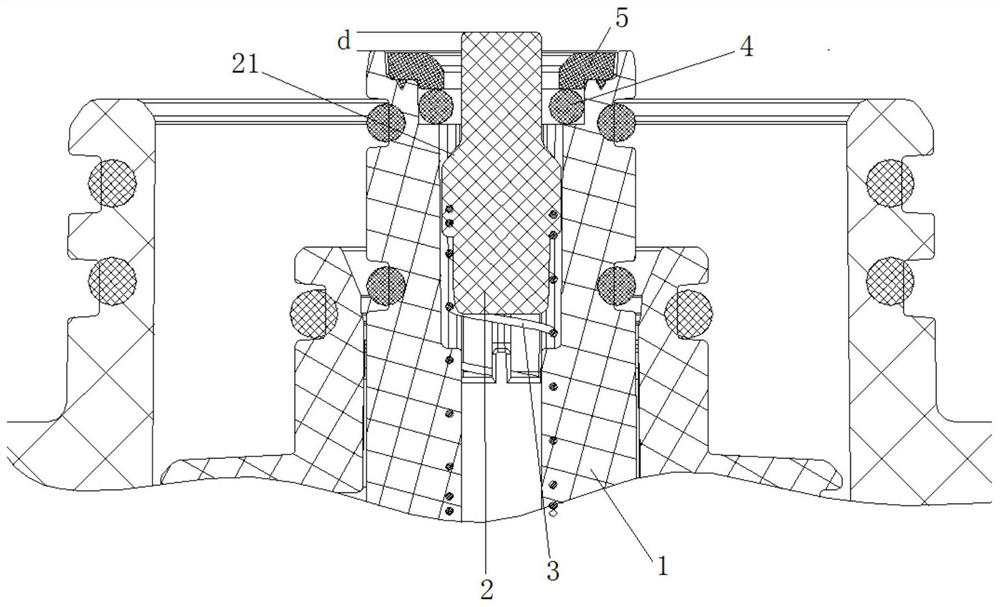

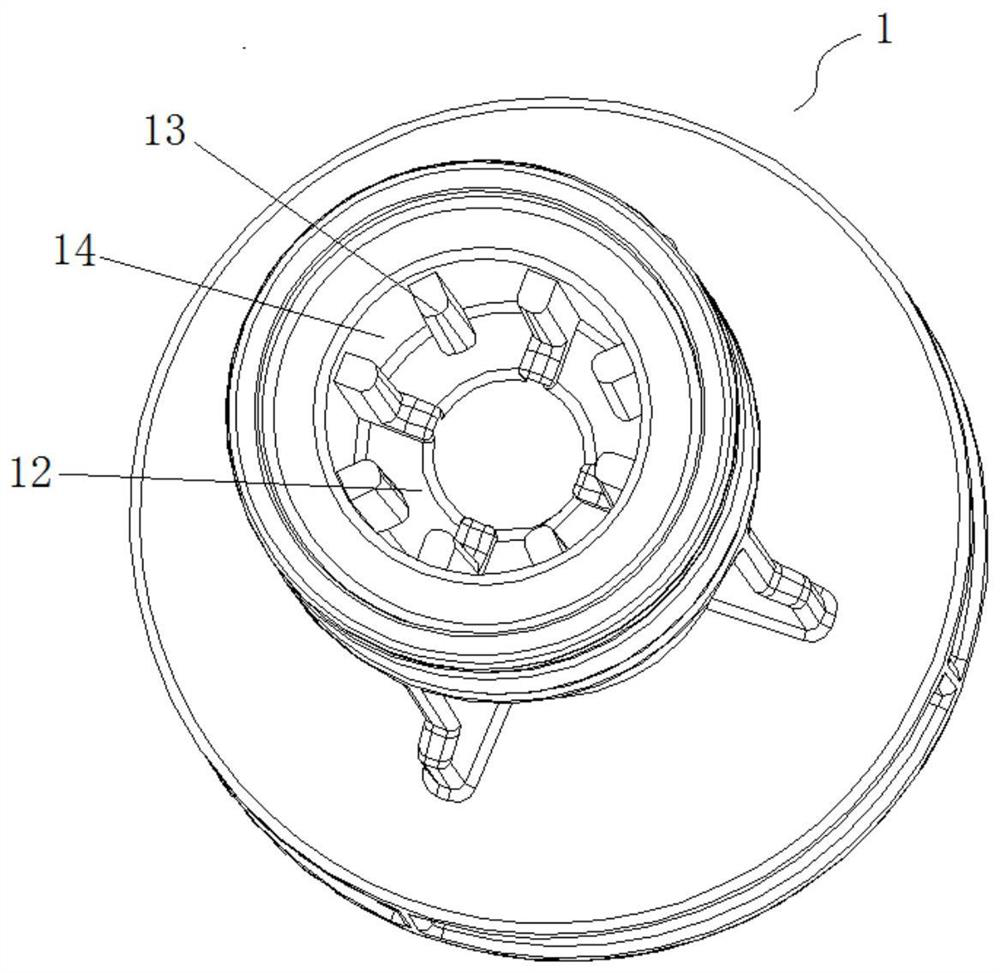

[0051] Such as Figure 1 to Figure 5As shown, a nozzle sealing structure provided in this embodiment includes: a substrate, on which a nozzle is formed, and a sealing groove 11 and a guide groove 12 formed at the nozzle, the sealing groove 11 and the guide groove 12 are arranged in communication; The water rod 2 is set on the guide groove 12 in a linear reciprocating manner under the action of the driving member 3; the sealing member 4 is arranged on the sealing groove 11; Under the action of the sealing part 21 abuts on the sealing member 4 .

[0052] In the sealing structure of the nozzle in this embodiment, the sealing member 4 is installed in the sealing groove 11. When the water stop rod is reciprocating, the sealing part 21 on it abuts against the sealing member 4 to realize the sealing at the nozzle. This design In this way, the seal 4 will not move together with the water stop rod 2, avoiding the wear of the seal 4, and the same water stop rod 2 is not installed with ...

Embodiment 2

[0065] Such as Figure 6 As shown, a filter element provided in this embodiment includes the nozzle sealing structure described in the above-mentioned embodiment 1, and a filter element body 6, the filter element body 6 is provided with a pure water channel 61, and the central rod 1 is set on the pure water On the water channel 61, the central rod 1 is inserted in the end of the pure water channel near its outlet in an interference fit manner, and a sealing ring structure is installed at the contact between the outer peripheral surface of the central rod 1 and the inner wall of the pure water channel to prevent water leakage .

Embodiment 3

[0067] This embodiment provides a water purification device, specifically a drinking water purifier commonly used in daily life, which includes the filter element in the above-mentioned embodiment 2, and has all its technical advantages, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com