Depth micrometer verification special-purpose testing fixture and verification method

A technology of depth micrometer and inspection tool, which is applied in the direction of micrometer, mechanical depth measurement, angle/taper measurement, etc., and can solve problems such as high roughness requirements, low work efficiency, and easy-to-scratch platforms 4

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention provides a special inspection tool and inspection method for depth micrometer verification, especially a special inspection tool and inspection method for detecting the parallelism between the measurement surface of the measuring rod and the measurement surface of the bottom plate during the inspection process of the depth micrometer. The following is combined with the accompanying drawings And the specific embodiment will further illustrate the present invention.

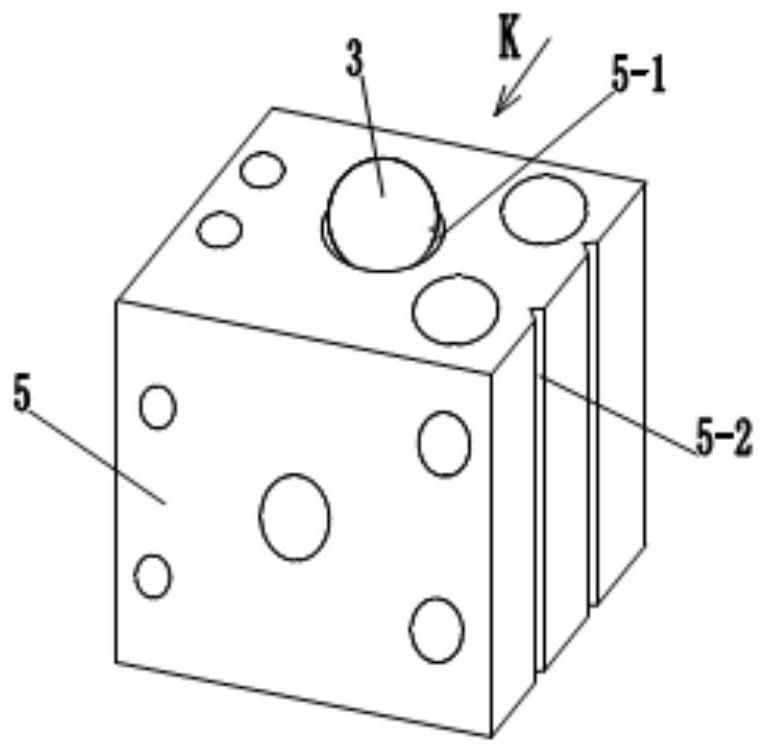

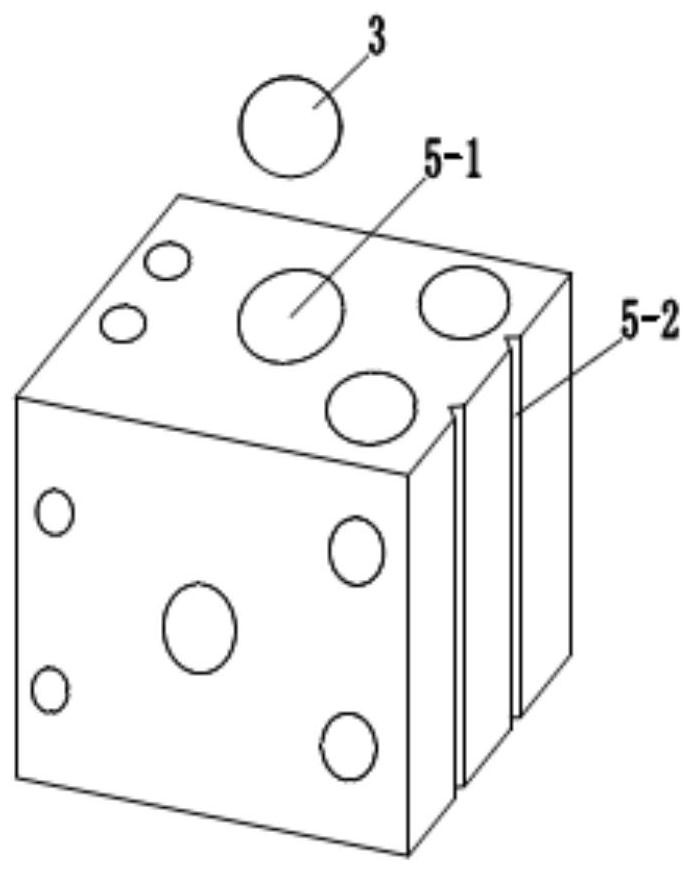

[0035] See Figure 2, image 3 , Figure 4 , Figure 5 , the special inspection tool for depth micrometer verification according to the present invention includes a rectangular measuring block 5 and a standard steel ball 3; the rectangular measuring block 5 is provided with several groups of circular grooves 5-1 of different sizes and specifications on its outer surface, The bottom surface of the circular groove 5-1 is a spherical arc surface; the standard steel balls 3 are configured in sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com