Lobe mixer capable of generating swirling jet

A mixer and lobe technology, which is applied to the structural design of forced mixers in an aero-engine afterburner, can solve the problems of increased weight and mixing loss, complicated connection structure of lobe mixers, etc., and achieves low mixing loss and simple structure. , enhance the effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

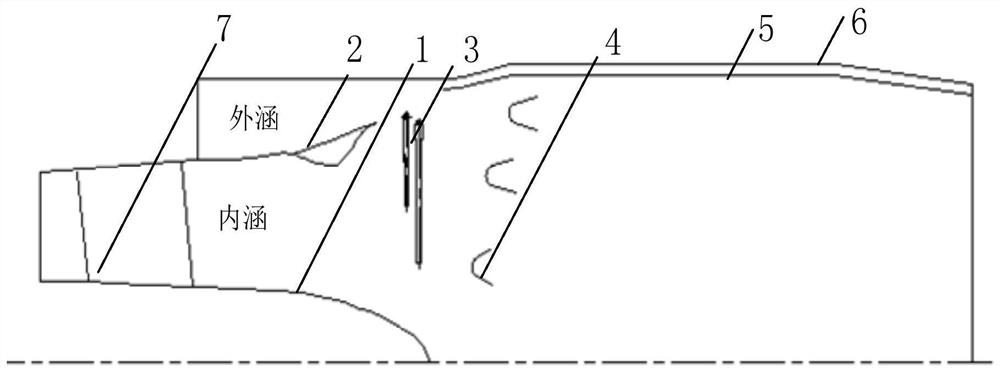

[0023] Such as figure 1 Shown is that the existing forced mixing afterburner includes a central cone 1 , a lobe mixer 2 , an afterburner fuel manifold 3 , a stabilizer 4 , a heat shield 5 , an outer wall of the cylinder 6 and a straightening strut 7 . The lobe mixer makes the internal high-temperature gas behind the support plate mix with the external low-temperature gas, and then the fuel injection is burned behind the stabilizer, which further increases the gas enthalpy and engine thrust. For small and medium bypass specific afterburners, the oxygen content of the inner gas is low and the temperature is high, and the oxygen content of the outer gas is high, but the temperature is low. The lobe mixer makes the temperature of the outer side after the mixer rise, Intrinsic oxygen content increased to improve afterburner efficiency.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com