Double-layer vibration isolation device

A vibration isolation and double-layer technology, applied in the direction of non-rotational vibration suppression, etc., can solve the problems that cannot meet the accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

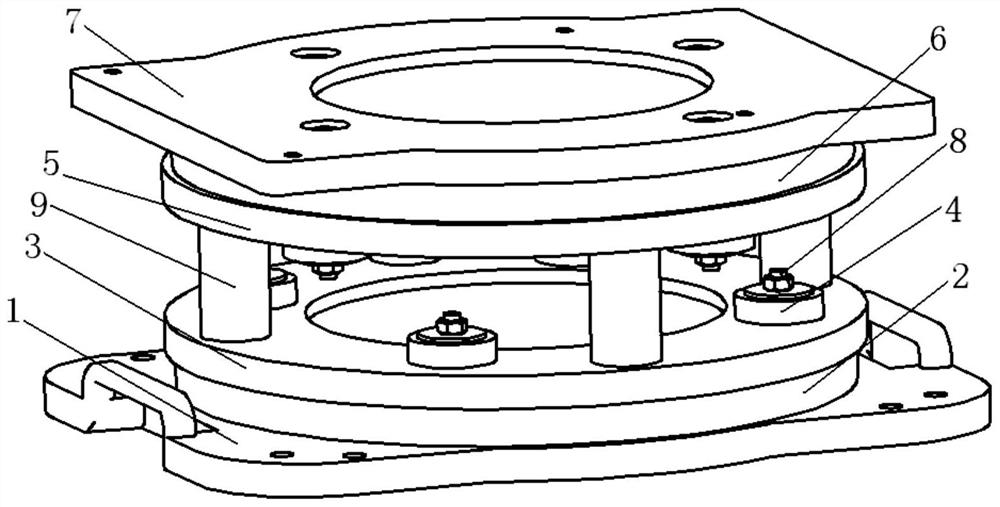

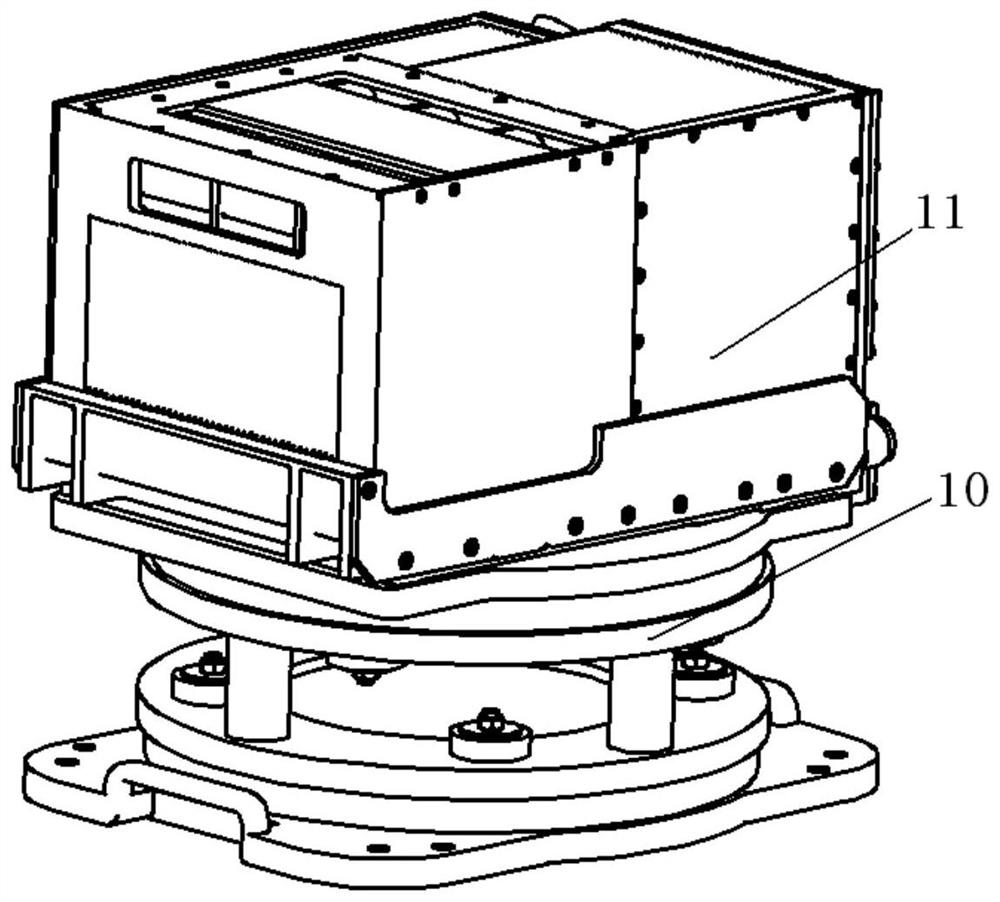

[0016] Such as figure 1 As shown, a double-layer vibration isolation device includes nine parts: first-level static platform 1, first-level isolation pad 2, first-level dynamic platform 3, bolt isolation pad 4, second-level static platform 5, second-level isolation pad 6, Secondary moving platform 7, bolt 8, column 9.

[0017] Among them, the first-level static platform 1 is the base of the vibration isolation device, which is used for external installation and provides an installation interface, and there are two wrenches on it to facilitate handling; the circular groove structure in the middle of the first-level static platform 1 is for reducing vibration. The heavy tank, the first-level isolation pad 2 is made of foam rubber material, located between the first-level static platform 1 and the first-level dynamic platform 3, the three-layer structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com