A mud strip cutting device for purple clay teapot

A cutting device and a technology for a purple sand teapot, which are applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of cumbersome operation process, labor consumption, low work efficiency, etc., and achieve the effects of simple operation, improved work efficiency, and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

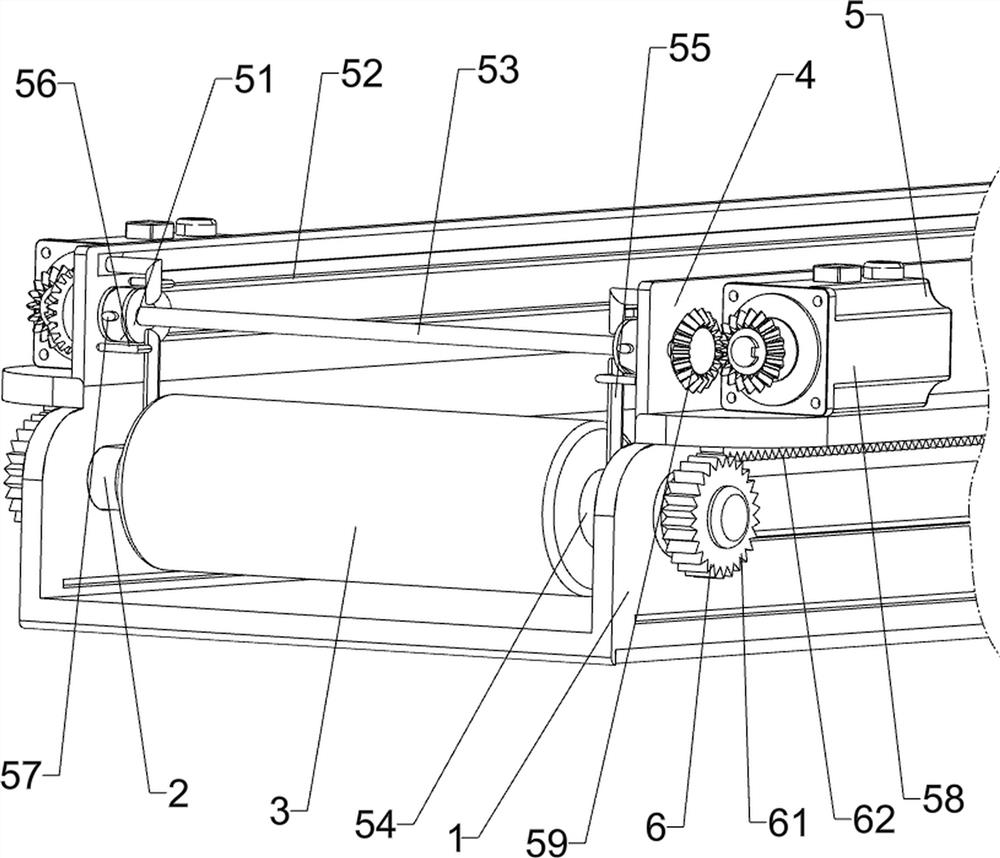

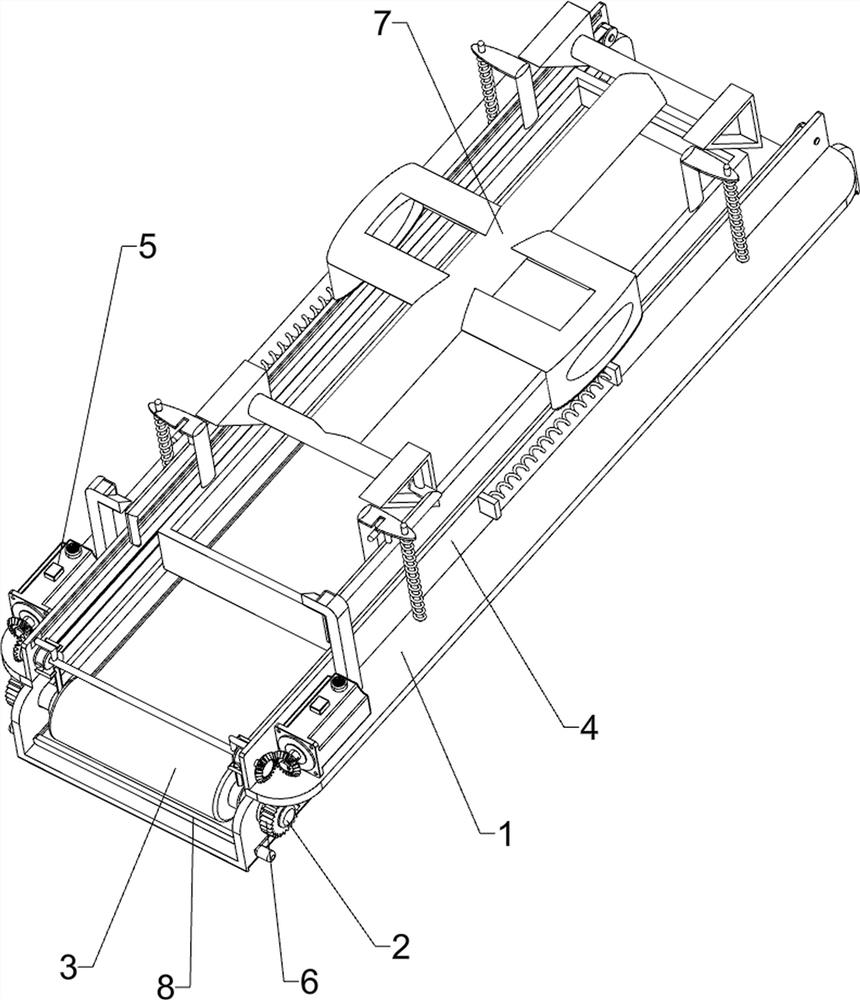

[0023] A mud strip cutting device for a purple clay teapot, such as Figure 1-2 As shown, it includes a bottom plate 1, a rotating shaft 2, a pressure roller 3 and a mounting plate 4. A rotating shaft 2 is slidably connected to the bottom plate 1, and the rotating shaft 2 is rotatably matched with the bottom plate 1. Both sides are connected with a mounting plate 4 , and also include a driving mechanism 5 and a transmission mechanism 6 .

[0024] The driving mechanism 5 includes a sprocket 51, a chain 52, a connecting rod 53, a collar 54, an L-shaped bar 55, a stop bar 56, a push block 57, a motor 58 and a bevel gear 59, and the front and rear sides of the mounting plate 4 are all rotationally connected. There is a sprocket 51, a chain 52 is wound between the two sprockets 51, a connecting rod 53 is connected between the two sprockets 51 on the front side, and the left and right sides of the rotating shaft 2 are rotatably connected with a collar 54. An L-shaped bar 55 is conn...

Embodiment 2

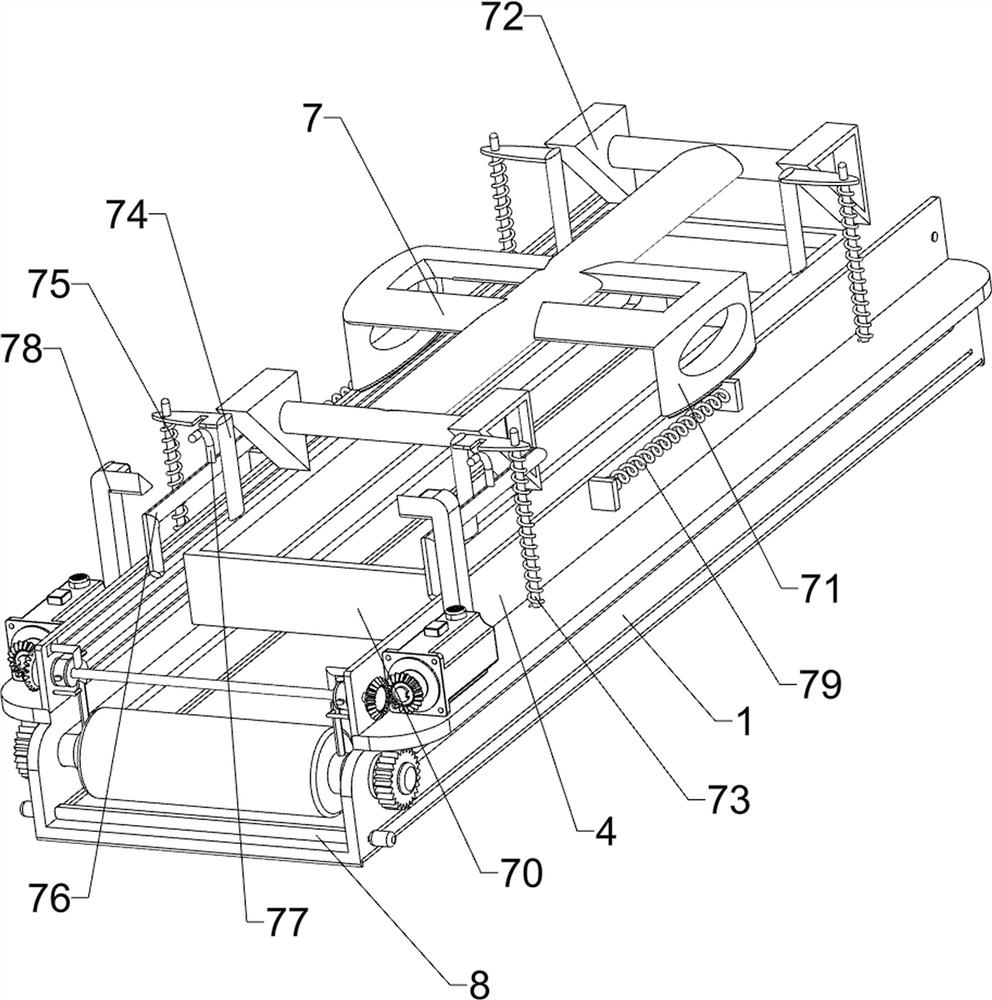

[0028] On the basis of Example 1, such as image 3 As shown, cutting mechanism 7 is also included, and cutting mechanism 7 includes rectangular blade 70, sliding seat 71, wedge block 72, sliding bar 73, cross bar 74, return spring 75, sliding bar 76, push rod 77, inclined bar 78 And tension spring 79, sliding type is connected with slide seat 71 between the mounting plate 4 tops on both sides, and two wedge-shaped blocks 72 are all connected with two wedge-shaped blocks 72 on the front and rear sides of slide seat 71, and are connected with two slide bars on the left and right sides of mounting plate 4 tops 73, the slide bar 73 is slidingly connected with a cross bar 74, the wedge block 72 cooperates with the cross bar 74, and a return spring 75 is connected between the cross bar 74 and the mounting plate 4, and the two wedge blocks 72 on the front side are all sliding A sliding rod 76 is connected, and a push rod 77 is connected to the sliding rod 76. A slanting rod 78 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com