Aluminum profile finished product saw cutting sizing device and aluminum profile fixed cutting process

A technology for aluminum profiles and finished products, which is applied in the direction of sawing machine devices, sawing machine accessories, metal sawing equipment, etc., can solve problems such as loose fixation and low precision, and achieve high automation, improve production efficiency, and improve automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

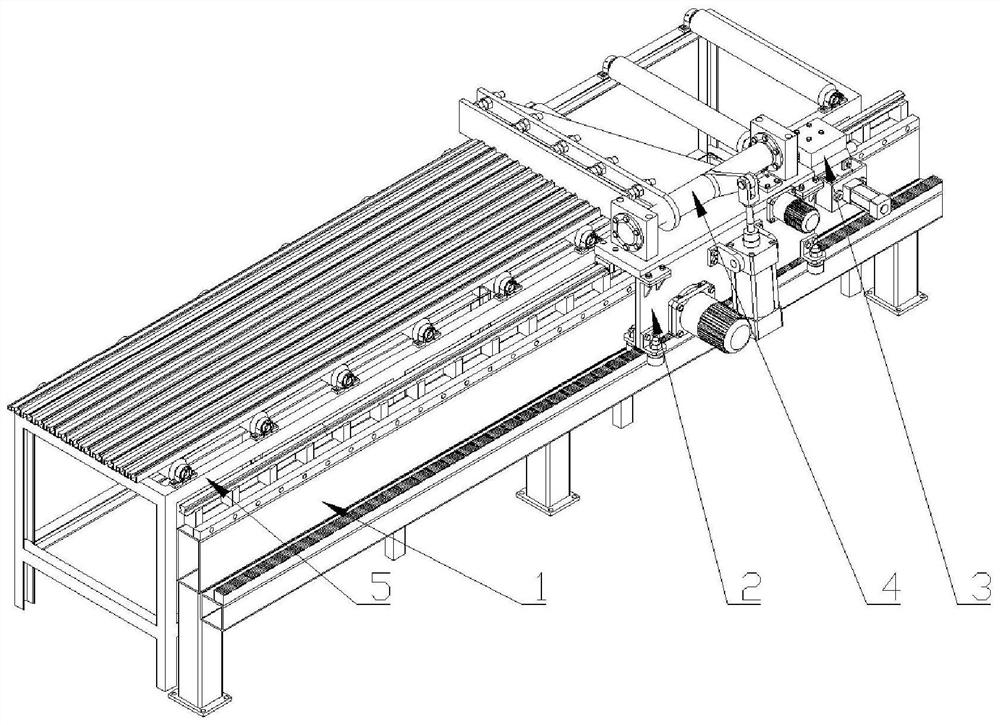

[0055] A sawing and sizing device for finished aluminum profiles, comprising a frame 1, a traveling mechanism 2, a positioning mechanism 3, and a baffle mechanism 4; wherein,

[0056]In the preferred solution of this embodiment, the frame 1 is arranged on one side of the conveying device 5 along the conveying direction; several positioning holes 107 are provided on the frame 1 along the length direction of the frame 1, so that The rack 1 further includes a slide rail 106 and a rack guide rail 104 , and the slide rail 106 and the rack guide rail 104 are both extended and arranged on the rack 1 along the length direction of the rack 1 .

[0057] In the preferred solution of this embodiment, the walking mechanism 2 is configured to move on the frame 1 along the length direction of the frame 1; The anti-deflection structure at the bottom of the main body 201, the power structure connected to the walking main body 201, and the first slider 203 connected to the walking main body 201...

Embodiment 2

[0076] This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and is further described on the basis of it:

[0077] A sawing and sizing device for finished aluminum profiles, comprising a frame 1, a traveling mechanism 2, a positioning mechanism 3, and a baffle mechanism 4; wherein,

[0078] In the preferred solution of this embodiment, the frame 1 is arranged on one side of the conveying device 5 along the conveying direction; on the frame 1 there are several equidistantly arranged positioning points along the length direction of the frame 1. hole 107, the positioning hole 107 is perforated along the horizontal direction perpendicular to the conveying direction of the conveying device, and the frame 1 also includes a slide rail 106 and a rack guide rail 104, and the slide rail 106 and the rack guide rail 104 are both Extended along the length direction of the frame 1 on the frame 1, the height of the rack guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com