Gravel mixing device for constructional engineering

A technology of mixing device and construction engineering, applied in mixers, transportation and packaging, chemical/physical processes, etc., can solve the problems of low dispersion of sand and gravel, poor mixing adequacy, etc. Efficient mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

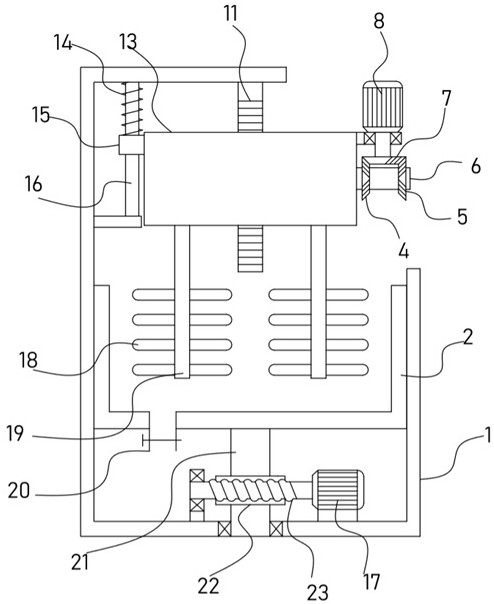

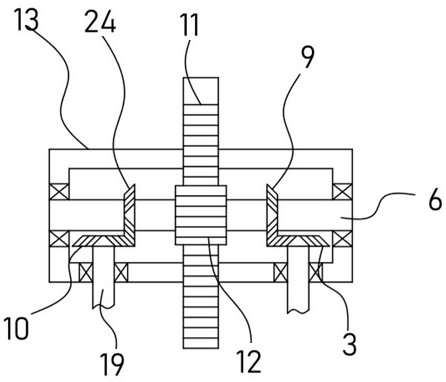

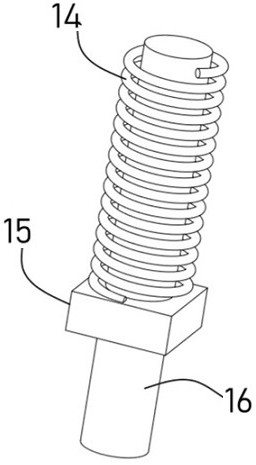

[0020] see Figure 1-3 , a construction engineering sand and gravel material mixing device, comprising a fixed frame 1, the fixed frame 1 is provided with a mixing tank 2 for storing sand and gravel materials, the bottom of the material mixing tank 2 is equipped with a discharge pipe 20, and the fixed frame 1 is provided with There is a steering mechanism for driving the rotation of the mixing tank 2. A transmission box 13 is slidably installed on the fixed frame 1 through a vertical guide mechanism, and a drive motor 8 is fixed on the transmission box 13. The drive motor 8 is driven and connected to a The transmission mechanism in 13 is driven and connected with two stirring shafts 19 vertically extending to the mixing tank 2 on the transmission mechanism, and several pairs of stirring rods 18 are fixed on the stirring shaft 19 at equal intervals.

[0021] The mixing tank 2 set in this device is used to store the sand and gravel materials to be stirred and mixed. The mixing t...

Embodiment 2

[0025] On the basis of Embodiment 1, in addition, the drive motor 8 of the device is driven and connected with an incomplete bevel gear 7, and the incomplete bevel gear 7 is alternately meshed with a bevel gear II4 and a bevel gear set and fixed on the drive shaft 6. Gear III5. The driving motor 8 drives the incomplete bevel gear 7 to rotate, and the incomplete bevel gear 7 alternately meshes with the bevel gear II4 and bevel gear III5. At this time, the drive shaft 6 rotates clockwise and counterclockwise alternately, that is, the drive shaft 6 can drive the transmission cylindrical gear 12 forward and reverse The hour hand rotates alternately. At this time, under the action of the spur rack 11, the transmission cylindrical gear 12 drives the drive shaft 6 together with the transmission box 13 to vertically reciprocate up and down, that is, the stirring rod 18 can vertically reciprocate up and down to realize the internal adjustment of the mixing tank 2. Thorough mixing of sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com