Method for solving pump end face profile data of three-blade rotating cam rotor

A lobe lobe pump, line data technology, applied in image data processing, special data processing applications, complex mathematical operations, etc., can solve the problem of difficult to accurately match the design and production of three-blade rotary lobe lobe pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

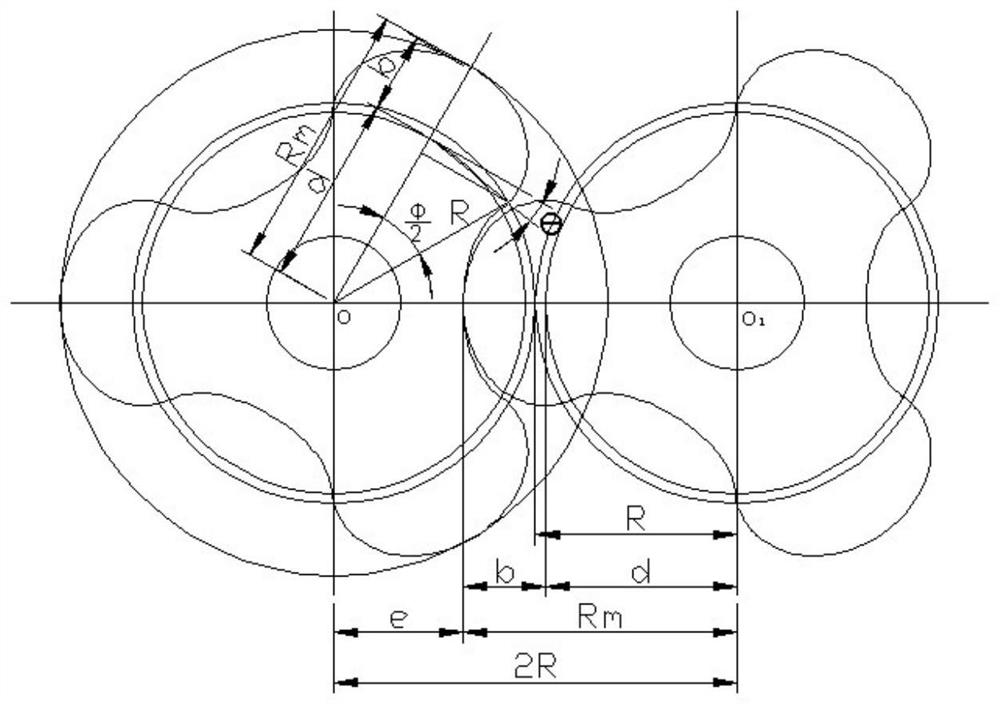

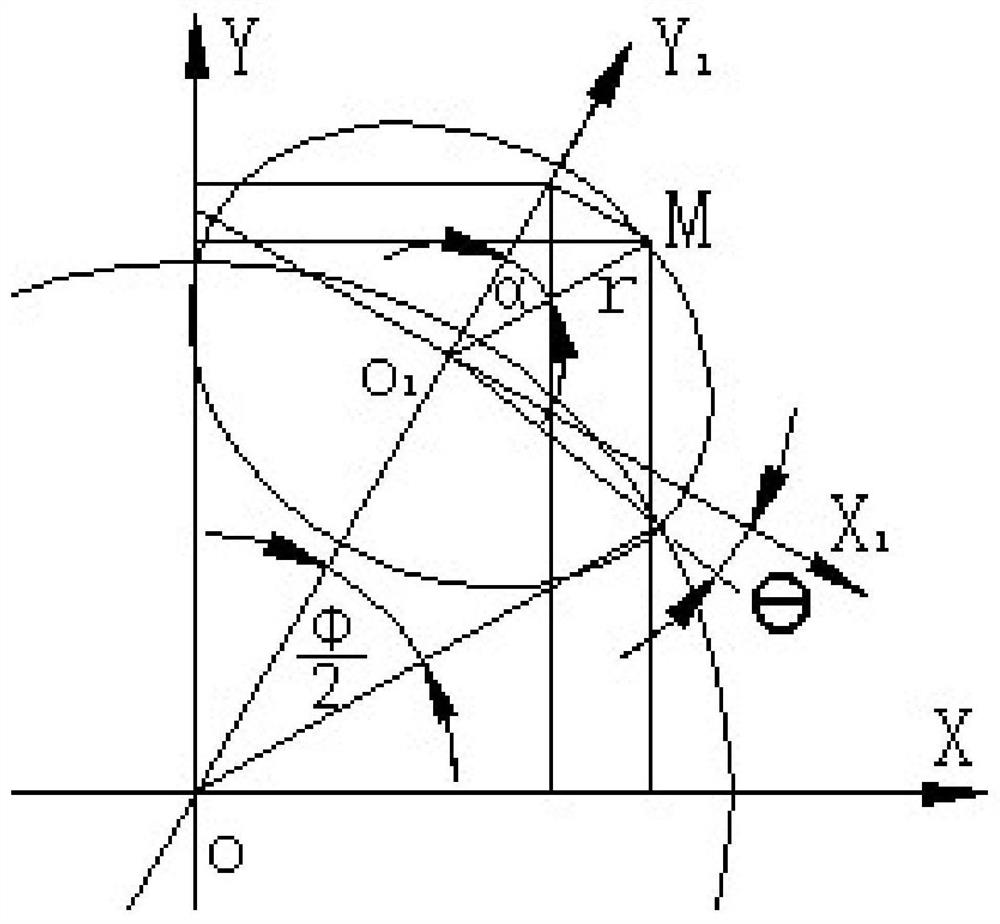

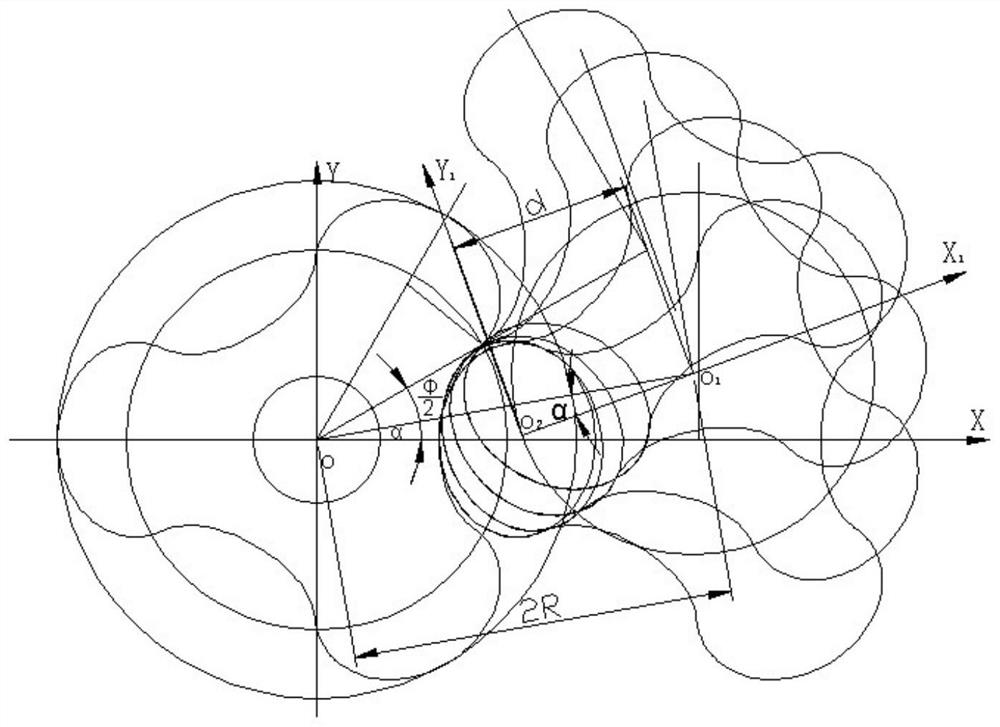

[0045] Reference attached Figures 1 to 6 , a method for calculating end surface profile data of a three-lobe rotary lobe rotor pump, comprising the following steps:

[0046] Step S1, the calculation of the semi-major and minor axes a and b of the ellipse; according to the condition that the peak and valley boundary points of the elliptic curve are on the pitch circle line, the following equation is established:

[0047]

[0048] y=Xtgθ=0.5Rtgθ (2)

[0049] In formulas (1) and (2), R is the radius of the rotor pitch circle, φ angle is 60°, and θ is the boundary point angle; according to the elliptic equation

[0050]

[0051] Substitute equations (1) and (2) into (3) to get the equation

[0052] b 2 =0.16R 2 (1+1.5625tg 2 θ) (4)

[0053] At the same time based on

[0054] b=Rm-Rcos30°-0.5Rtgθ (5)

[0055] From the formulas (4) and (5), the para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com