Alkali metal atom vacuum sample source based on all-glass material and implementation method

An alkali metal, all-glass technology, used in instruments, measuring instrument components, measuring devices, etc., can solve the problems of heavy mass, large device size, and unfavorable integration and engineering of quantum sensor physical probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with examples of implementation. It should be understood that the examples of implementation described here are only for illustration and explanation of the present invention, and are not intended to limit the present invention.

[0051] 1. Vacuum sample source of alkali metal atoms based on all-glass material.

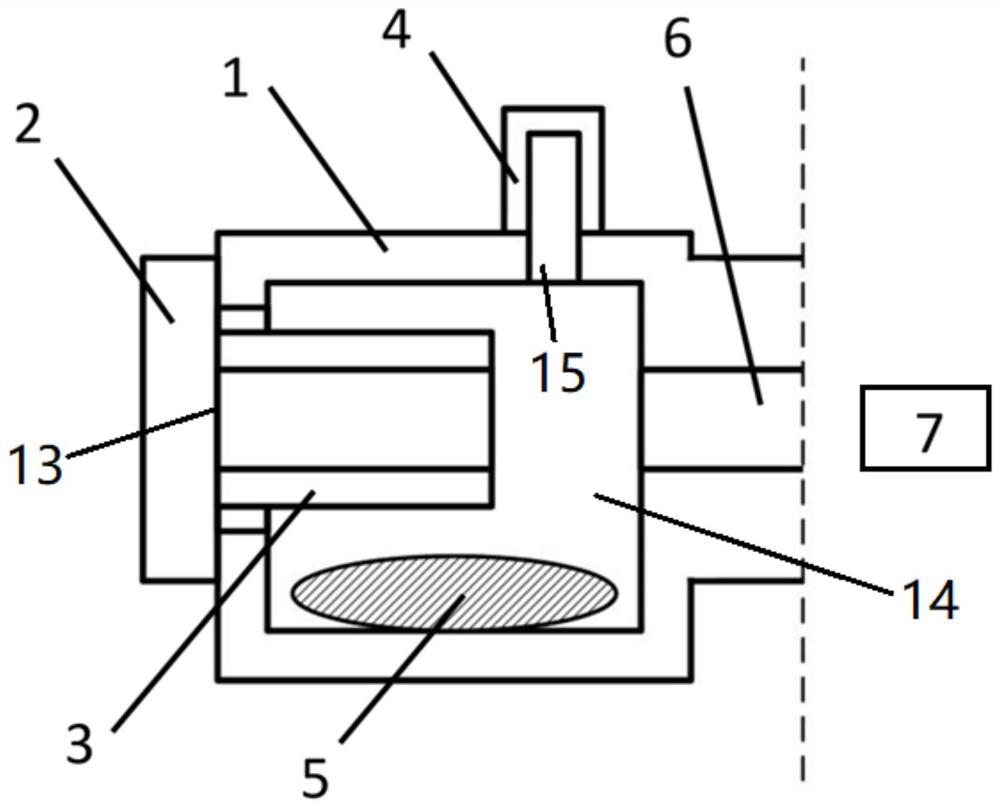

[0052] A.Overall

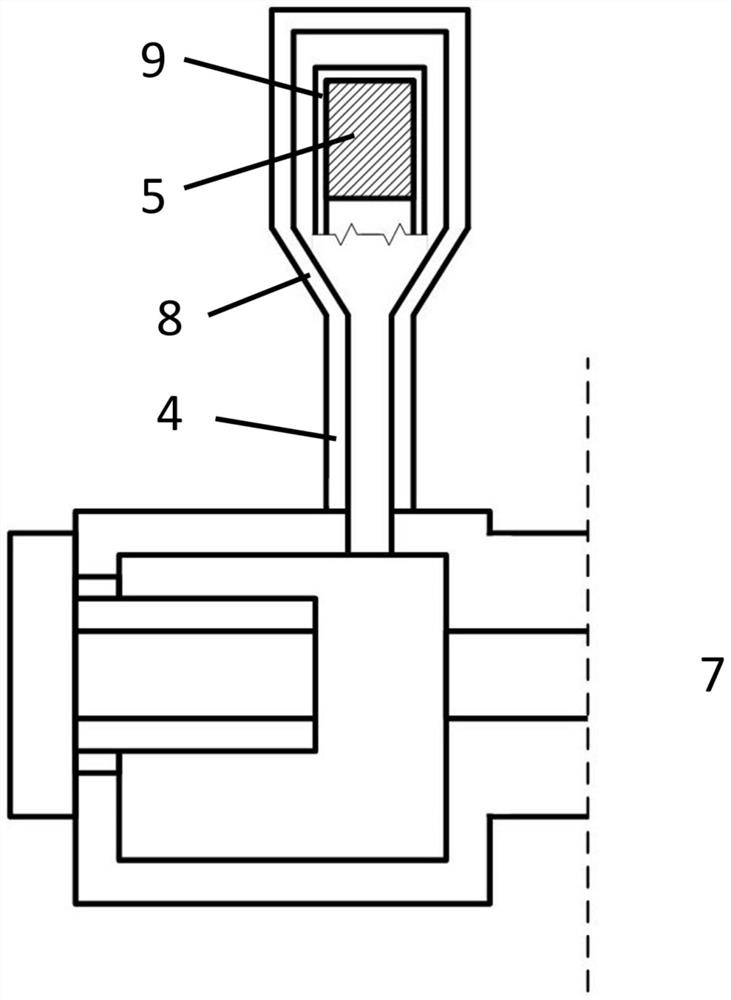

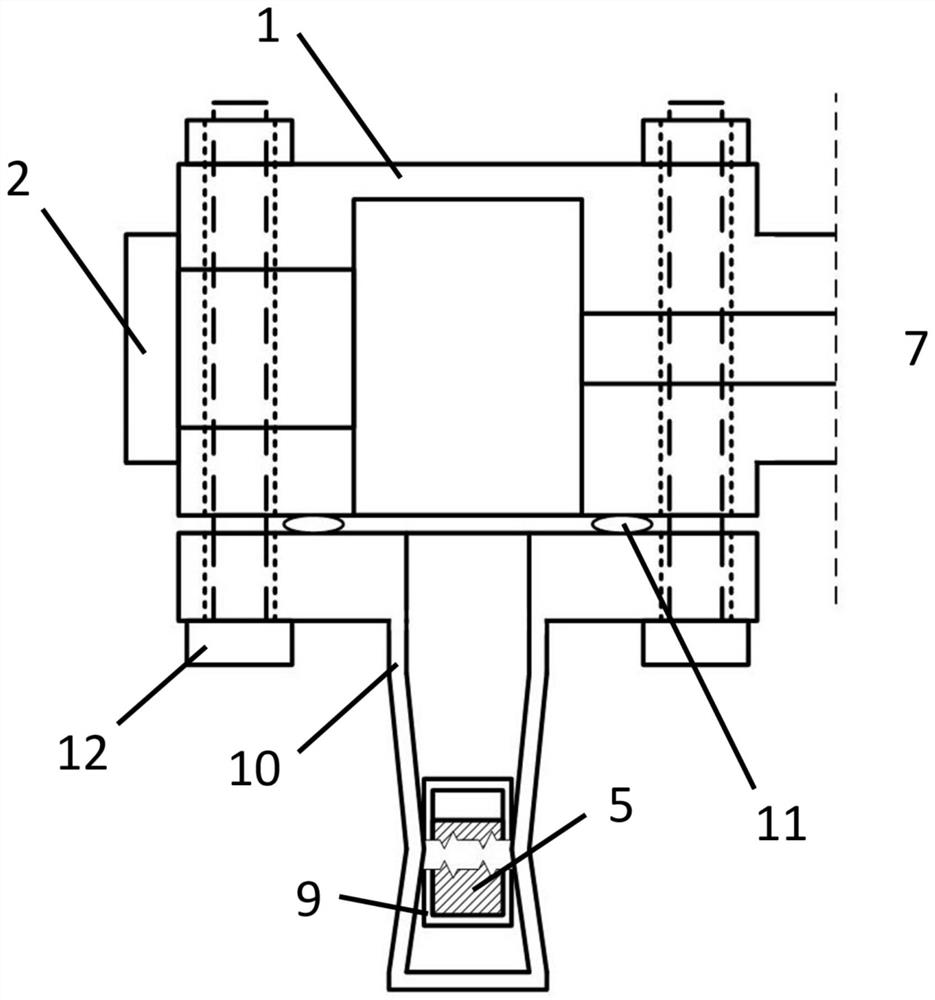

[0053] like figure 1 As shown, the vacuum sample source of alkali metal atoms based on an all-glass material includes a vacuum vessel body 1 , an optical window 2 , an anti-evaporation hole 3 , a filling transition tube 4 and an alkali metal sample 5 . The main body 1 of the vacuum vessel, the optical window 2, the anti-evaporation hole body 3, and the filling transition tube 4 are all made of glass materials (including optical glass, quartz, glass-ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com