Three-dimensional patterned surface for enhancing dropwise condensation

A three-dimensional pattern, drop-shaped condensation technology, applied in the fields of condensation and heat and mass transfer, can solve the problems of reducing the size of the condensate detachment in the drop-shaped area, and achieve the effect of increasing the boundary perimeter, strong practicability, and promoting the final detachment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

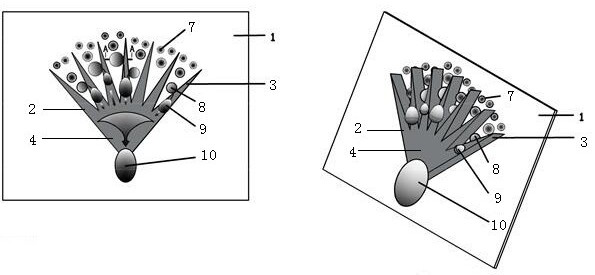

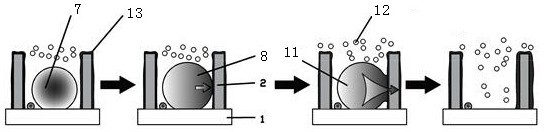

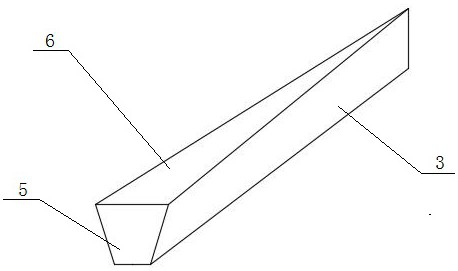

[0028] refer to Figure 1-3 , an embodiment of the present invention provides a three-dimensional patterned surface that enhances droplet condensation, including a superhydrophobic substrate 1 and an upwardly convex superhydrophilic three-dimensional pattern 2 disposed on the superhydrophobic substrate 1, the upwardly convex superhydrophilic pattern 2 The three-dimensional pattern 2 includes seven convex super-hydrophilic three-dimensional structures 3 and droplet collection areas 4, each of which is connected in sequence, and the droplet collection area 4 is located on the convex super-hydrophilic three-dimensional structure 3 Below: the vertical distance between the convex super-hydrophilic three-dimensional structure 3 and the super-hydrophobic substrate 1 is 500 μm, which reduces the detachment of the condensate in the drop-shaped area to the size of the film-like area and improves the condensation efficiency; the convex-shaped super-hydrophilic The three-dimensional struc...

Embodiment 2

[0030]An embodiment of the present invention provides a three-dimensional patterned surface that enhances drop-like condensation, including a superhydrophobic substrate 1 and an upwardly convex superhydrophilic three-dimensional pattern 2 disposed on the superhydrophobic substrate 1. The upwardly convex superhydrophilic three-dimensional pattern 2 Pattern 2 includes nine convex superhydrophilic three-dimensional structures 3 and droplet collection areas 4, each of which is connected in turn to form a cluster combination, and the droplet collection area 4 is located below the cluster combination; The vertical distance between the convex super-hydrophilic three-dimensional structure 3 and the super-hydrophobic substrate 1 is 800 μm; the convex super-hydrophilic three-dimensional structures 3 are connected in sequence, and the nine convex super-hydrophilic three-dimensional structures 3 form three clusters Cluster combination, the angle between adjacent convex superhydrophilic thr...

Embodiment 3

[0032] An embodiment of the present invention provides a three-dimensional patterned surface that enhances drop-like condensation, including a superhydrophobic substrate 1 and an upwardly convex superhydrophilic three-dimensional pattern 2 disposed on the superhydrophobic substrate 1. The upwardly convex superhydrophilic three-dimensional pattern 2 Pattern 2 includes nine convex superhydrophilic three-dimensional structures 3 and droplet collection areas 4, each of which is connected in sequence, and the droplet collection area 4 is located below the convex superhydrophilic three-dimensional structure 3 The vertical distance between the convex super-hydrophilic three-dimensional structure 3 and the super-hydrophobic substrate 1 is 1000 μm; the convex super-hydrophilic three-dimensional structure 3 is connected in sequence, and a plurality of convex super-hydrophilic three-dimensional structures 3 form a group Cluster combination, the angle between adjacent convex superhydrophil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com