A kind of plastic liner of high pressure composite container

A composite container and liner technology, which is applied to pressure vessels, container discharge methods, and outer walls of container structures. It can solve problems such as reduced sealing performance and loose connections, and achieves the effect of strong resistance to multiple pressure and temperature changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in detail by the following examples. The following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations on the technical solutions of the present invention.

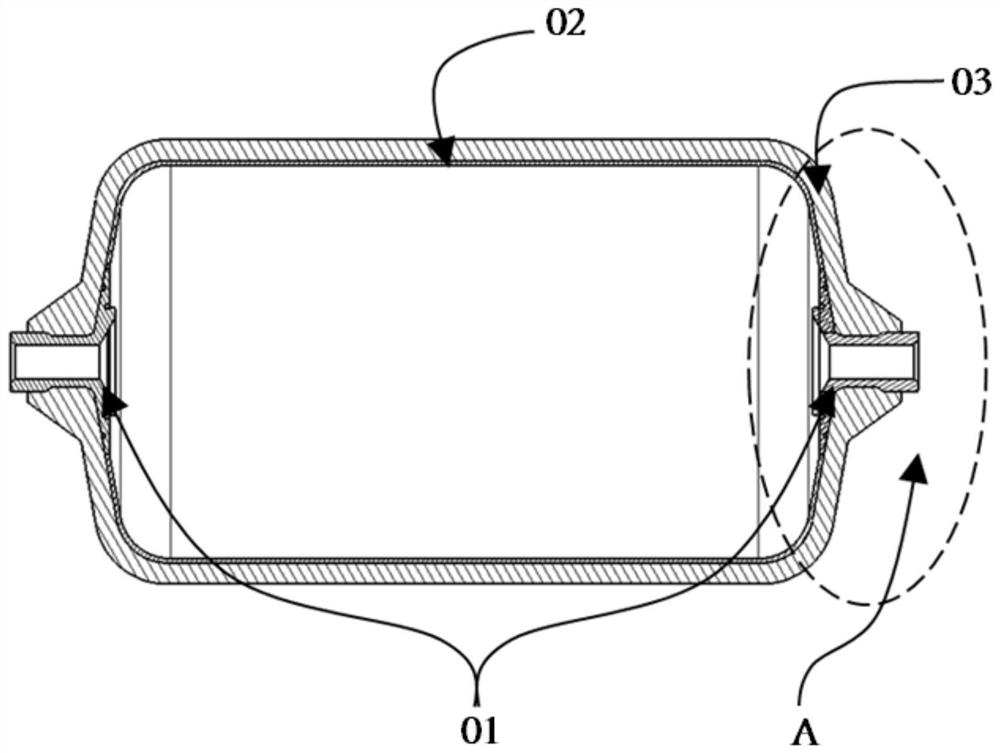

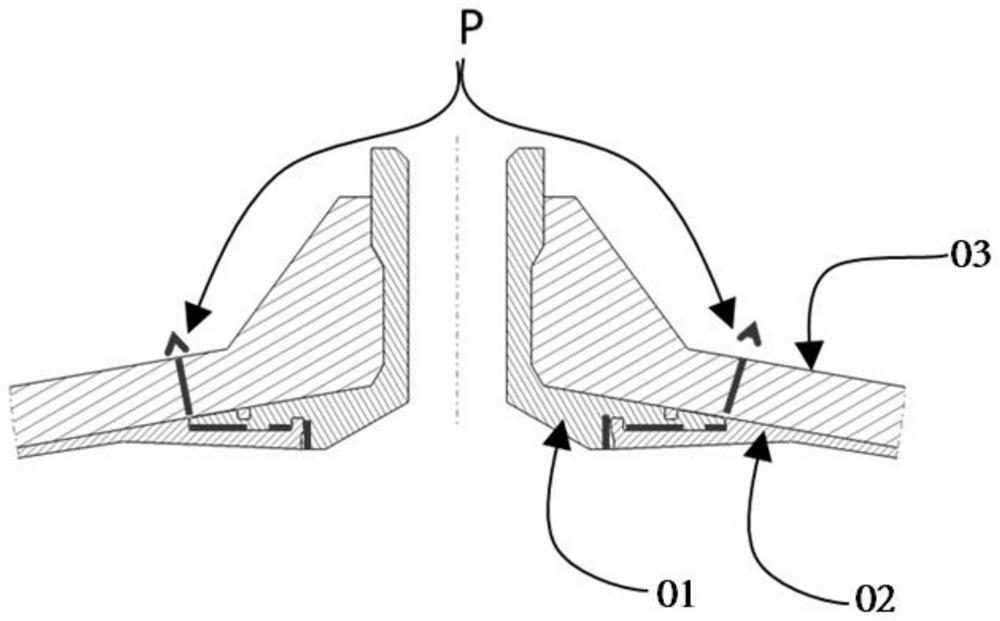

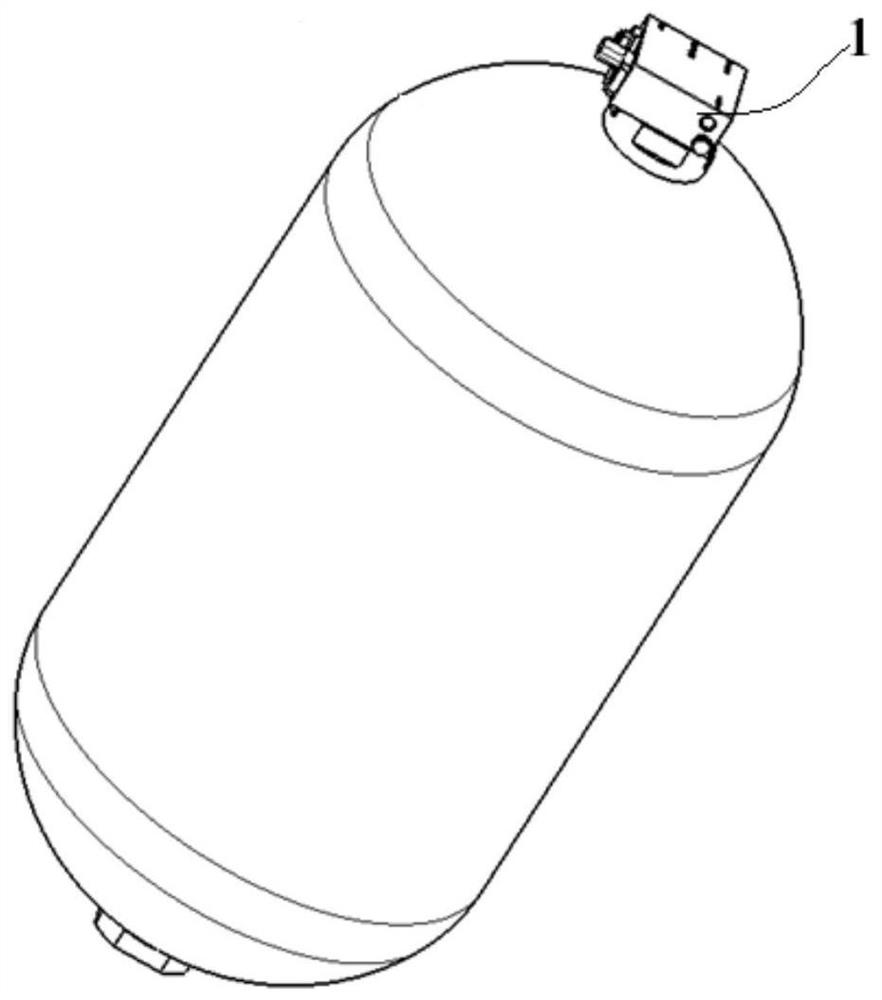

[0031] like image 3 As shown, the present application is a technical solution related to a plastic liner of a high-pressure composite container for storing high-pressure gaseous media, and a bottle valve 1 with a certain system function is also provided on the plastic liner.

[0032] The type of high-pressure gas used to store high-pressure gas does not need to be limited in this application. All gases that require high-pressure storage can be applied to this high-pressure composite container, such as hydrogen, CNG, helium, nitrogen, etc. The pressure is greater than 1MPa, such as 10MPa, 20MPa, 30MPa, 50MPa, 70MPa, 80MPa or higher pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com