Novel box type pneumatic actuator

A pneumatic actuator, box-type technology, applied in the direction of engine components, mechanical equipment, fluid pressure actuators, etc., can solve the problems of inconvenience, low cost, no take out, etc., and achieve high adjustment accuracy, convenient maintenance, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

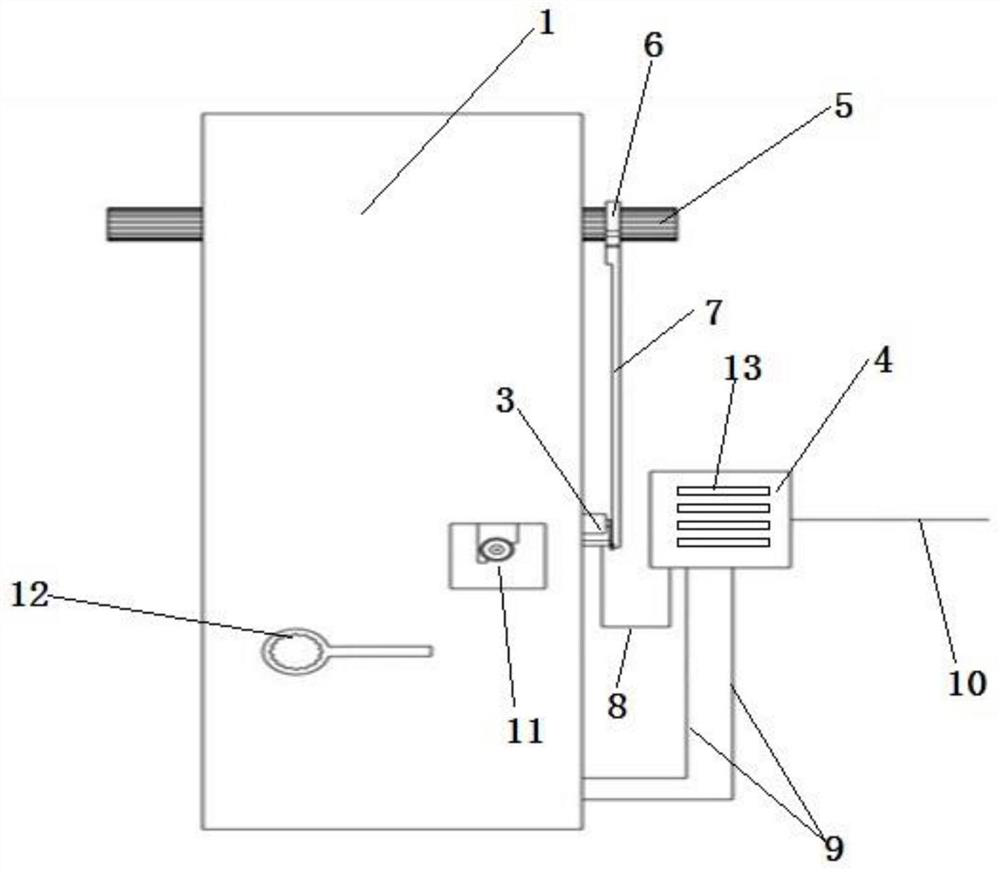

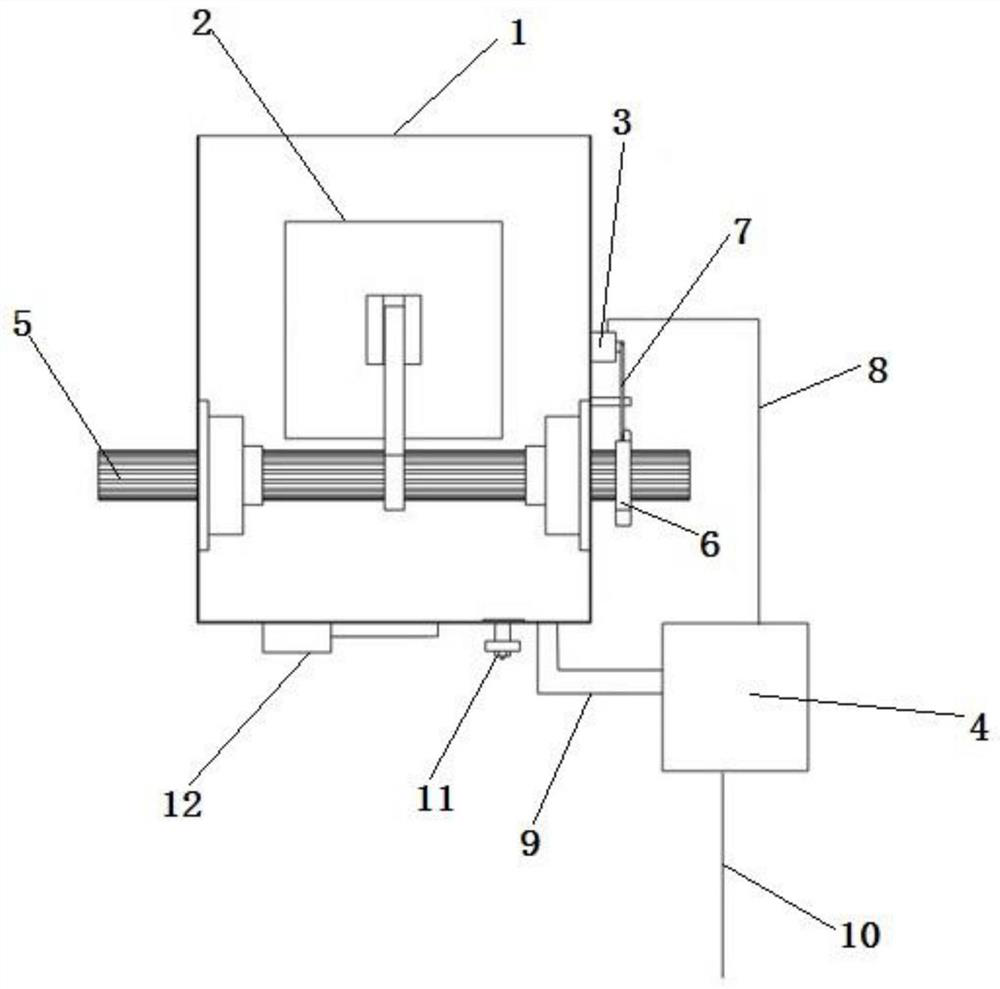

[0030] like figure 1 , figure 2 As shown, a new box-type pneumatic actuator includes a box body 1, a cylinder 2 located inside the box body 1, a signal feedback device 3 fixed on the outer wall of the box body 1, and a positioner 4 arranged outside the box body 1, The inside of the box 1 is provided with a horizontal horizontal spindle 5 connected to the cylinder 2 adjacent to its top. One end of the device 4 is provided with a universal joint 6, and a universal joint connecting rod 7 is arranged below the universal joint 6, and the universal joint 6 is connected with the signal feedback device 3 through the universal joint connecting rod 7, and the signal feedback device A signal cable 8 is provided between 3 and the positioner 4, and a signal gas source pipeline 9 is provided between the positioner 4 and the cylinder 2. The side of the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com