Pure-plane solid wood floor and production process thereof

A technology of solid wood flooring and plane, which is applied in the direction of wood processing equipment, floors, impregnated wood, etc., can solve the problems of increasing the difficulty of cleaning the ground with solid wood flooring and affecting the appearance of the pavement, so as to achieve integrity and beauty, Good for cleaning and sanitation, and the effect of increasing tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

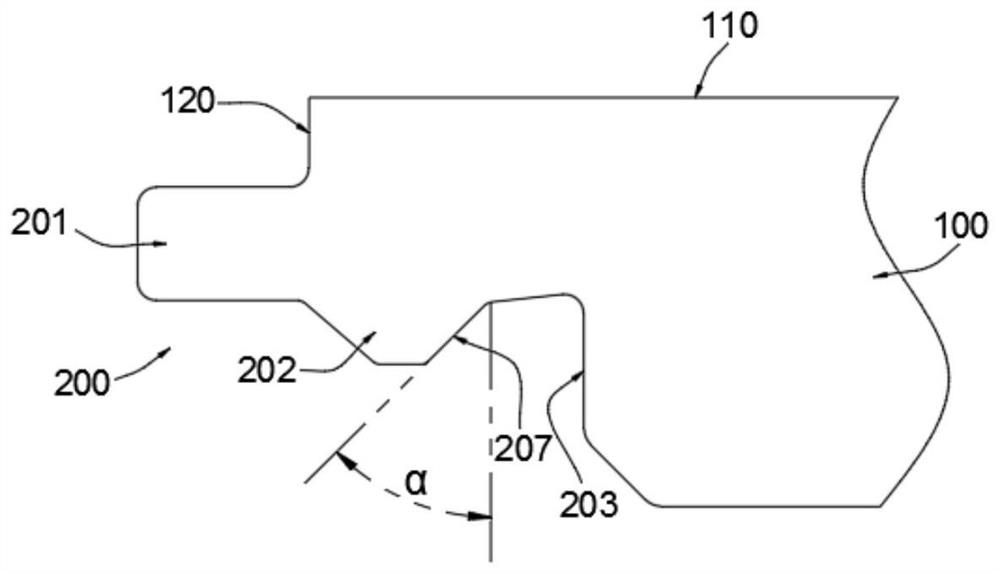

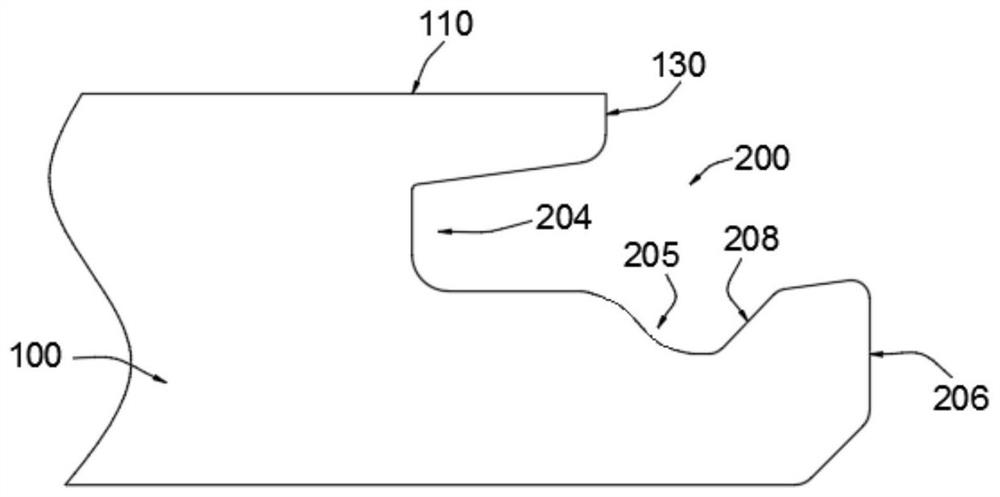

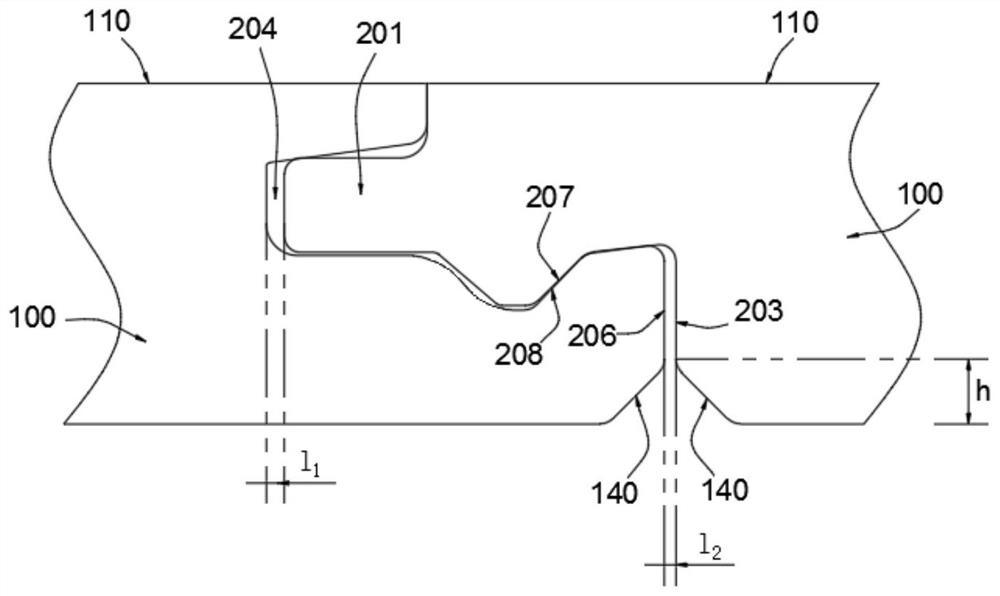

[0050] Example 1: Reference figure 1 , figure 2 The pure-planar solid wood floor shown includes a floor block body 100 and a locking structure 200 arranged on the periphery of the floor block body 100. The locking structure 200 includes a male and female tenon part formed by milling. When the floorboard body 100 is rectangular, the male tenon component includes a long-side male tenon arranged on the long side of the floorboard body 100, a short-side male tenon arranged on the short side of the floorboard body 100, and the long-side male tenon and the short side The male tenons are respectively located on the two male tenon sides 120 of the floorboard body 100; the female tenon components include a long-side female tenon arranged on the long side of the floorboard body 100 and a short-side female tenon arranged on the short side of the floorboard body 100, The long side tenon and the short side tenon are respectively located on the two dowel sides 130 of the floorboard body 100;...

Embodiment 2

[0054] Example 2: The difference between Example 2 and Example 1 is that reference Figure 4 , Figure 5 As shown, there is an obtuse angle β of 97~103° between the side 130 of the female tenon and the surface 110 1 After assembling, the side surface 120 of the male tenon and the side surface 130 of the female tenon are in surface contact fit. For example, there is an obtuse angle β of 100° between the side surface 130 of the female tenon and the surface 110 1 , There is an acute angle β of 80° between the side 120 of the male tenon and the surface 110 2 . Pass β 1 And β 2 When the local plate body 100 shrinks too much, the surface coordination between the two inclined surfaces can visually eliminate the gap between the male side 120 and the female side 130 to a certain extent. Moreover, as is well known to those skilled in the art, in order to smoothly assemble the male part into the female part, the upper top surface of the female part 204 is inclined. 97~103° obtuse angle β ...

Embodiment 3

[0055] Example 3: The difference between Example 3 and Example 1 is that reference Image 6 , Figure 7 As shown, there is an obtuse angle β of 97~103° between the side 130 of the female tenon and the surface 110 3 After assembling, an acute angle γ of 1 to 3° is formed between the side surface of the male tenon 120 and the side surface of the female tenon 130. For example, there is an obtuse angle β of 98° between the side 130 of the dowel and the surface 110 3 , There is an acute angle β of 80° between the side 120 of the male tenon and the surface 110 4 Therefore, after assembling, the upper edges of the male tenon side surface 120 and the female tenon side surface 130 abut against each other, and an acute angle γ of 2° is formed between the male tenon side surface 120 and the female tenon side surface 130. Therefore, compared with the technical solution of the second embodiment, the installation noise caused by the surface contact between the male tenon side surface 120 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com